Abstract

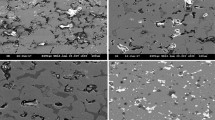

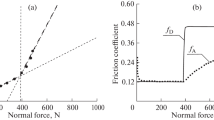

The present study discusses sliding wear characteristics of a gray cast iron over a range of applied loads in oil lubricated condition. Effects of MoS2 and graphite addition to the oil lubricant in governing the wear behavior have also been studied. The wear rate increased with load in general with a few exceptions in the case of oil plus 5% MoS2 wherein it had a tendency to show a reverse trend in the intermediate load range. Addition of 5% graphite to the oil brought about a decrease in the wear rate without affecting seizure resistance. Increasing quantity of graphite in the oil from 5 to 10% practically did not affect the wear rate at lower loads. However, it led to significantly lower wear rates at higher loads and also offered higher seizure resistance. In the case of oil plus 5% MoS2 lubricant mixture, the wear rate of the samples was higher than that of the lubricant with 5% graphite when tests were conducted at lower loads while identical response was observed at higher loads in both cases. Seizure resistance of the samples was not affected by the addition of 5% graphite and MoS2 to the oil. The frictional heating also increased with load in general, except in the case of oil containing 5% MoS2 and 10% graphite wherein it remained practically unaffected in the intermediate load range. The presence of 5% graphite and MoS2 in the oil lubricant brought about reduced frictional heating, except in the case of oil plus 5% graphite mixture wherein the trend reversed, and oil plus 5% MoS2 leading to comparable frictional heating during specimen seizure. Increasing test duration caused higher frictional heating. Adhesion was observed to be the principal wear mechanism while microcracking assisted delamination and abrasion also contributed to material loss.

Similar content being viewed by others

References

C.V. White, Gray Iron, Metals Handbook: Properties, Selection: Irons, Steels, High Performance Materials, Vol. 1, 10th ed., ASM, Materials Park, Ohio, USA, 1990, p 12–32

Y. Zhang, Y. Chen, R. He, and B. Shen, Investigation of Tribological Properties of Brake Shoe Materials—Phosphorous Cast Irons with Different Graphite Morphologies, Wear, 1993, 166, p 179–186

T.S. Eyre, Friction, Wear of Cast Irons, Metals Handbook: Friction, Lubrication, Wear Technology, Vol. 10, 18th ed., ASM, Materials Park, Ohio, USA, 1992, p 695–701

M. Yazun, Z. Wancheng, L. Shengna, J. Yuansheng, W. Yuscong, and T.C. Simon, Tribological Performance of Three Advanced Piston Rings in the Presence of MoDTC-Modified GF-3 Oils, Tribol. Lett., 2005, 18, p 75–83

F.J. Clauss, Solid Lubricants and Self-Lubricating Solids, Chapter 5, Handbook of Tribology, B. Bhushan and B.K. Gupta, Ed., McGraw Hill Inc., USA, 1991, p 5.1–5.86.

R.H. Boehringer, Grease, Metals Handbook: Friction, Lubrication, Wear Technology, Vol. 10, 18th ed., ASM, Materials Park, Ohio, USA, 1992, p 123–131

S.Q.A. Rizvi, Lubricant Additives and Their Functions, Metals Handbook: Friction, Lubrication, Wear Technology, Vol 10, 18th ed., ASM, Materials Park, Ohio, USA, 1992, p 98–112

B.K. Prasad and O.P. Modi, Sliding Wear Response of Zinc-Based Alloy as Affected by Suspended Solid Lubricant Particles in Oil Lubricant, Tribol. Mater. Surf. Interfaces, 2008, 2, p 84–91

B.K. Prasad, Lubricated Sliding Wear Behaviour of a Cast Iron: Effect of Graphite and/or Talc Fraction in Oil, J. Mater. Eng. Perform., 2010, 19, p 413–420

F. Wilson and T.S. Eyre, Addition of Graphite Particles to Oil Lubricants, Lubr. Eng., 1973, 29, p 65–72

T.H.C. Childs and F. Sabbagh, Boundary-Lubricated Wear of Cast Irons to Simulate Automotive Piston Ring Wear Rates, Wear, 1989, 134, p 81–97

B.K. Prasad, Effectiveness of an Externally Added Solid Lubricant on the Sliding Wear Response of a Zinc–Aluminium Alloy, its Composite and Cast Iron, Tribol. Lett., 2005, 18, p 135–143

J. Gansheimer and R. Holinski, Molybdenum Disulfide in Oils and Greases Under Boundary Lubrication, Trans. ASME J. Lubr. Technol., 1973, 95, p 242–248

B.K. Gupta and B. Bhushan, Fullerene Particles as an Additive to Liquid Lubricants and Greases for Low Friction and Wear, Lubr. Eng., 1994, 50, p 524–528

S. Qiu, Z. Zhou, J. Dong, and G. Chen, Preparation of Ni Nanoparticles and Evaluation of their Tribological Performance as Potential Additives in Oils, Trans. ASME J. Tribol., 2001, 123, p 441–443

G. Liu, X. Li, N. Lu, and R. Fan, Enhancing AW/EP Property of Lubricant Oil by Adding Nano Al/Sn Particles, Tribol. Lett., 2005, 18, p 85–90

L. Rapoport, V. Leshchinsky, I. Lapsker, Yu. Volovik, O. Nepomnyashchy, M. Lvovsky, R. Popovitz-Biro, Y. Feldman, and R. Tenne, Tribological Properties of WS2 Nanoparticles Under Mixed Lubrication, Wear, 2003, 255, p 785–793

US Patent No. 1714565 (1927) to W. Koehler, US Patent No. 2156803 (1934) to H.S. Cooper and V.R. Damuet, US Patent No. 2284785 (1939) to J.E. Wikey

W.O. Winer, Molybdenum Disulfide as a Lubricant: A Review of the Fundamental Knowledge, Wear, 1967, 10, p 422–452

A.A. Elsharkawy, Effects of Lubricant Additives on the Performance of Hydrodynamically Lubricated Journal Bearings, Tribol. Lett., 2005, 18, p 63–73

R.B. Rastogi and M. Yadav, Suspension of Molybdenum–Sulphur Complexes in Paraffin Oil as Extreme Pressure Lubricants, Tribol. Int., 2003, 36, p 511–516

T. Hisakado, T. Tsukizoe, and H. Yoshikawa, Lubrication Mechanism of Solid Lubricants in Oils, Trans. ASME J. Lubr. Technol., 1983, 105, p 245–253

B.K. Prasad, Sliding Wear Characteristics of a Gray Cast Iron as Influenced by the Sliding Speed, Load and Environment, Tribol. Mater. Surf. Interfaces, 2008, 2, p 128–138

B.K. Prasad, Sliding wear behaviour of a cast iron as affected by test environment and applied load, Ind. Lubri. Tribol., 2009, 61, p 161–172

B.K. Prasad, Influence of Suspended Talc Particles in Oil and Nature of Material Microconstituents on Sliding Wear Characteristics of Cast Iron and Zinc-Based Alloy, Can. Metall. Q., 2009, 48, p 455–464

B.K. Prasad, Sliding Wear Response of Cast Iron as Influenced by Microstructural Features and Test Condition, Mater. Sci. Eng. A, 2007, 456A, p 373–385

B.K. Prasad, Sliding Wear Response of Spheroidal Graphite Cast Iron as Influenced by Applied Pressure, Sliding Speed and Test Environment, Can. Metall. Q., 2008, 47, p 495–507

B.K. Prasad, Sliding Wear Response of a Cast Iron Under Varying Test Environments and Traversal Speed and Pressure Conditions, Wear, 2006, 260, p 1333–1341

P.K.D. Poddar and M. Chaudhuri, Chapter 2, Natural Minerals, Handbook of Ceramics, S. Kumar, Ed., Kumar and Associates Publishers, Calcutta, 1994, p 53–104

Wikipedia, The Free Encyclopedia, Graphite, http://en.wikipedia.org

P.J. Bryant, P.L. Gutshall, and L.H. Taylor, A Study of Mechanisms of Graphite Friction and Wear, Wear, 1964, 7, p 118–126

R.H. Savage, Graphite Lubrication, J. Appl. Phys., 1948, 19, p 1–10

H.E. Sliney, Solid Lubricants, Metals Handbook: Friction, Lubrication, Wear Technology, Vol. 10, 18th ed., ASM, Materials Park, Ohio, USA, 1992, p 113–122

Y. Lakhtin, Chapter 1, Crystal Structure of Metals, Engineering Physical Metallurgy, 1st ed., Mir Publishers, Moscow, 1963, p 11–24

A.F. Wells, Structural Inorganic Chemistry, Clarendon Press, Oxford, 1984

T. Bartels, Lubricants and Lubrication, Ullman’s Encyclopedia of Industrial Chemistry, Wiley VCH, Weinheim, 2002

P.K. Rohatgi, R. Asthana, and S. Das, Solidification, Structures, and Properties of Cast Metal-Ceramic Particle Composites, Int. Met. Rev., 1986, 31, p 115–139

P.K. Rohatgi, S. Ray, and Y. Liu, Tribological Properties of Metal Matrix-Graphite Particle Composites, Int. Mater. Rev., 1992, 37, p 129–152

G. Rowe, Some Observations on the Frictional Behaviour of Boron Nitride and of Graphite, Wear, 1960, 3, p 274–285

B.S. Mazumdar, A.H. Yegneswaran, and P.K. Rohatgi, Strength and Fracture Behaviour of Metal Matrix Particulate Composites, Mater. Sci. Eng., 1984, 68, p 85–96

B.K. Prasad and S. Das, The Significance of Matrix Microstructure on the Solid Lubrication Characteristics of Graphite in Aluminium Alloys, Mater. Sci. Eng. A, 1991, 144A, p 229–235

B.K. Prasad, A.K. Patwardhan, and A.H. Yegneswaran, Microstructure and Property Characterization of a Modified Zinc-Based Alloy and Comparison with Bearing Alloys, J. Mater. Eng. Perform., 1998, 7, p 130–135

B.K. Prasad, A.K. Patwardhan, and A.H. Yegneswaran, Factors Controlling the Dry Sliding Wear Behaviour of a Leaded-Tin Bronze, Mater. Sci. Technol., 1996, 12, p 427–435

S. Das, S.V. Prasad, and T.R. Ramachandran, Tribology of Al–Si Alloy-Graphite Composites: Triboinduced Graphite Films and the Role of Silicon Morphology, Mater. Sci. Eng. A, 1991, 138A, p 123–132

B.K. Prasad, A.K. Patwardhan, and A.H. Yegneswaran, Wear Characteristics of a Zinc-Based Alloy Compared with a Conventional Bearing Bronze Under Mixed Lubrication Condition: Effects of Material and Test Parameters, Can. Met. Q., 2001, 40, p 193–210

M.H. Cho, S.J. Kim, R.H. Basch, J.W. Fash, and H. Jang, Tribological Study of Gray Cast Iron with Automotive Brake Linings: The Effect of Rotor Microstructure, Tribol. Int., 2003, 36, p 537–545

A. Rac, Influence of Load and Speed on Wear Characteristics of Grey Cast Iron in Dry Sliding—Selection for Minimum Wear, Tribol. Int., 1985, 18, p 29–33

E. Takeuchi, The Mechanism of Wear of Spheroidal Graphite Cast Iron in Dry Sliding, Wear, 1972, 19, p 267–276

E. Takeuchi, The Mechanisms of Wear of Cast Iron in Dry Sliding, Wear, 1968, 11, p 201–212

R.S. Montgomery, The Mild Wear Mechanism of Nodular Iron, Wear, 1969, 13, p 337–343

Y.S. Lerner, Wear Resistance of Ductile Irons, J. Mater. Eng. Perform., 1994, 3, p 403–408

L. Fang, Y. Gao, L. Zhou, and P. Li, Unlubricated Sliding Wear of Ceramics Against Graphitized Cast Irons, Wear, 1994, 171, p 129–134

F. Wilson and T.S. Eyre, Effect of Matrix Structure and Hardness on the Wear Characteristics of an S.G. Cast Iron, Wear, 1969, 14, p 107–117

J.H. Zhu, P.K. Liaw, J.M. Corum, J.G.R. Hansen, and J.A. Cornie, Damage Mechanisms in a Cast Ductile Iron and a Al2O3p /Al Composite, Metall. Mater. Trans. A, 1998, 29A, p 2855–2862

A.K. Jha, B.K. Prasad, O.P. Modi, S. Das, and A.H. Yegneswaran, Correlating Microstructural Features and Mechanical Properties with Abrasion Resistance of a High Strength Low Alloy Steel, Wear, 2003, 254, p 120–128

M.V. Rayiko and N.F. Dmytrychenko, Some Aspects of Boundary Lubrication in the Local Contact of Friction Surfaces, Wear, 1988, 126, p 69–78

O.P. Modi, B.K. Prasad, A.H. Yegneswaran, and M.L. Vaidya, Dry Sliding Wear Behaviour of Squeeze Cast Aluminium Alloy-Silicon Carbide Composites, Mater. Sci. Eng. A, 1992, 151A, p 235–245

F.E. Kennedy, Jr., Thermal and Thermomechanical Effects in Dry Sliding, Wear, 1984, 100, p 453–476

L.H. Chen and D.A. Rigney, Transfer During Unlubricated Sliding Wear of Selected Metal Systems, Wear, 1985, 105, p 47–61

D.A. Rigney, L.H. Chen, M.G.S. Naylor, and A.R. Rosenfield, Wear Processes in Sliding Systems, Wear, 1984, 100, p 195–219

B.K. Prasad and S.V. Prasad, Microstructural Changes During Low-Stress Abrasion of a Plain Carbon (0.5% C) Steel, Wear, 1991, 151, p 1–12

B.R. Newcomb and W.M. Stobbs, A Transmission Electron Microscopy Study of the White Etching Layer on a Rail Head, Mater. Sci. Eng., 1984, 66, p 195–204

J. Larsen-Badse and K.G. Mathew, Influence of Structure on the Abrasion Resistance of 1040 Steel, Wear, 1969, 14, p 199–205

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prasad, B.K., Rathod, S., Yadav, M.S. et al. Sliding Wear Behavior of Cast Iron: Influence of MoS2 and Graphite Addition to the Oil Lubricant. J. of Materi Eng and Perform 20, 445–455 (2011). https://doi.org/10.1007/s11665-010-9689-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9689-y