Abstract

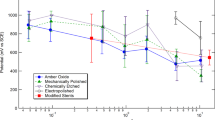

ASTM F 2129 test method nor the FDA provides any guidance as to what constitutes an acceptance criterion for the corrosion resistance of implantable medical devices. Neither provide any guidance on how many samples to test or how to handle censored data, i.e. datasets where there are only a few tests that breakdown. The development of both a statistically valid acceptance criterion for corrosion resistance and a method of evaluation would be of significant benefit to the medical device community. This study of 420 nitinol cyclic polarization tests, which builds on previous research that was presented at SMST 2007, investigates the effect of long-term exposure to simulated in vivo environments with differing degrees of aeration. This was accomplished by pre-exposing electropolished (EP) nitinol to phosphate buffered saline (PBS) at 37 °C that had been sparged with either ultra high purity nitrogen or laboratory air. Immersion times ranged from 1 h up to 30 days. A total of 290 EP samples were tested in order to obtain a reasonable number of samples with breakdown, i.e. pitted. In addition, a total of 130 mechanical polished (MP) samples were also analyzed. This data allow us to test our statistical model that was presented at SMST 2007. This model takes into account the probability of breakdown per unit of exposed surface area and, if breakdown occurs, predicts the probability that Eb − Er is greater than some threshold value. Aerated PBS environments were found to have a large influence on the margin of safety against pitting in vivo. Statistical methods for treating highly right censored pitting data are presented.

Similar content being viewed by others

Notes

Mann-Whitney Rank Sum Test (P = 0.101).

Mann-Whitney Rank Sum Test (P = 0.385).

Mann-Whitney Rank Sum Test (P = 0.001).

References

Clarke, B., et al., Influence of Nitinol wire surface treatment on oxide thickness and composition and its subsequent effect on corrosion resistance and nickel ion release. J Biomed Mater Res A, 2006. 79(1): 61–70.

Eiselstein, L.E., D.M. Proctor, and T.C. Flowers, Trivalent and Hexavalent Chromium Issues in Medical Implants. Materials Science Forum 539–543: p. pp. 698–703(2007).

J.J. Jacobs, J.L. Gilbert, and R.M. Urban, Current Concepts Review - Corrosion of Metal Orthopaedic Implants, The Journal of Bone and Joint Surgery, 1998, 80, p 268–282

“Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices,” ASTM F 2129-06, ASTM International Standard F 2129-06, Vol. 13.01, ASTM International, West Conshohocken, PA, 2006.

L. Eiselstein, et al., Toward an Acceptance Criterion for the Corrosion Resistance of Medical Devices: A Statistical Study of the Pitting Susceptibility of Nitinol, Proceedings of SMST-2007 the International Conference on Shape Memory and Superelastic Technologies, 2007, ASM International, Tsukuba City, Japan.

R.A. Corbett, Laboratory Corrosion Testing of Medical Implants, Proceedings of Materials and Processes for Medical Devices Conference, S. Shrivastava, Ed., ASM International, Materials Park, OH, 2004, p 166-171

R.A. Corbett and S.N. Rosenbloom, An Assessment of ASTM F 2129 Test Results Comparing Nitinol to Other Implant Alloys, SMST 2006: Proceedings of the International Conference on Shape Memory and Superelastic Technologies, 2006.

S.N. Rosenbloom and R. Corbett, “An Assessment of ASTM F 2129 Electrochemical Testing of Small Medical Implants—Lessons Learned,” Paper no. 07674, NACE 2007, Houston, TX, 2007.

B.G. Pound, Susceptibility of nitinol to localized corrosion. Journal of biomedical materials research. Part A, 2006. 77(1): p. 185–191.

G. Frankel, Pitting Corrosion, ASM Handbook, Vol 13A, S.D. Cramer and B.S. Covino Jr., Eds. ASM International, Materials Park, OH, 2003, p 236.

J.R. Scully and M.J. Kelly, Methods for Determining Aqueous Corrosion Reaction Rates, ASM Handbook, Vol 13A, S.D. Cramer and B.S. Covino Jr., Eds., ASM International, Materials Park, OH, 2003, p 68.

D. Silverman, “Tutorial on Cyclic Potentiodynamic Polarization Technique,” Paper no 299, CORROSION/98, NACE International, Houston, TX, 1998.

D. Silverman, Practical corrosion prediction using electrochemical techniques. In: R.W. Revie, editor. Uhlig’s Corrosion Handbook, 2nd ed. New York: Wiley; 2000. pp 1179–1225. 2000.

“Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants,” ASTM F 2063-05, Vol. 13.01, ASTM International, West Conshohocken, PA, 2005.

B.J. Burrow and J. Moskito, “Auger Electron Spectroscopy (AES) Surface Analysis Report,” Job Number: C07S6006, Evans Analytical Group, Sunnyvale, CA 94086, USA, 2007.

“Implants for Surgery—Measurements of Open-Circuit Potential to Assess Corrosion Behaviour of Metallic Implantable Materials and Medical Devices Over Extended Time Periods,” ISO 16429-04, Geneva, Switzerland. 2004.

T. Shibata, W.R. Whitney Award Lecture: Statistical and Stochastic Approaches to Localized Corrosion, Corrosion, 1996, 52(11), p 813–830

Kowaka, M., Introduction to Life Prediction of Industrial Plant Materials. (Allerton Press, Inc, New York, 1994).

T. Shibata, Corrosion Probability and Statistical Evaluation of Corrosion Data. In Uhlig’s Corrosion Handbook, R.W. Revie, Editor. (John Wiley & Sons, New York, 2000).

W.J. Conover, Practical Nonparametric Statistics, 2nd ed., Wiley Series in Probability and Mathematical Statistics, Wiley, New York, 1980.

S. Shabalovskaya, J. Anderegg, and J.V. Humbeeck, Recent Observations of Particulates in Nitinol, Mater. Sci. Eng. A, 2008, 481–482, p 431–436

S. Shabalovskaya, et al., The Effect of Surface Particulates on the Corrosion Resistance of Nitinol Wire, SMST-2003: The International Conference on Shape Memory and Superelastic Technologies, 2003, p 399–408.

J. Schaffer, A Probabilistic Approach to Modeling Microstructural Variability and Fatigue Behavior in ASTM F562 Medical Grade Wire, Presented May 19th, 2006 at the 9th International Fatigue Congress, Atlanta, USA. 2006.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at Shape Memory and Superelastic Technologies 2008, held September 21-25, 2008, in Stresa, Italy, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Eiselstein, L.E., Steffey, D., Nissan, A. et al. Acceptance Criteria for Corrosion Resistance of Medical Devices: Statistical Analysis of Nitinol Pitting in In Vivo Environments. J. of Materi Eng and Perform 18, 768–780 (2009). https://doi.org/10.1007/s11665-009-9420-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9420-z