Abstract

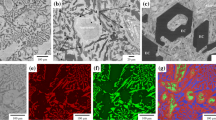

A 18.22 wt.% Cr white iron has been subjected to various destabilization heat treatments. Destabilization at 800 °C caused gradual precipitation of M23C6 secondary carbide particles with time leading to a gradual increase in the bulk hardness. At 900, 1000, and 1100 °C, an initial sharp increase in bulk hardness with time occurred, reaching a plateau that was followed by a slightly decreasing trend. The combination of martensite formed, stoichiometry, and morphology of the secondary carbides present (mostly M7C3) are responsible for the obtained values of hardness. At 1100 °C, severe dissolution of the secondary carbides and consequent stabilization of the austenitic phase took place. Maximum hardness values were obtained for destabilization at 1000 °C. The correlation between bulk hardness and microstructural features was elaborated.

Similar content being viewed by others

References

C.P. Tabrett, I.R. Sare, M.R. Ghomashchi, Microstructure-Property Relationships in High Chromium White Iron Alloys, Int. Mater. Rev., 41 (2), (1996), 52-89.

C.P Tabrett, I.R. Sare, The Effect of Heat Treatment on the Abrasion Resistance of Alloy White Irons, Wear, 203–204, (1997), 206-219.

C.P Tabrett, I.R. Sare, Effect of High Temperature and Sub-Ambient Treatments on the Matrix Structure and Abrasion Resistance of a High Chromium White Iron, Scr. Mater., 38 (12), (1998), 1747–1753.

O.N. Dogan, J.A. Hawk, G. Laird II, Solidification Structure and Abrasion Resistance of High Chromium White Irons, Metall. Mater. Trans., 28A, (1997), 1315-1328.

O.N. Dogan, J.A. Hawk, Effect of Carbide Orientation on Abrasion of High Cr White Cast Iron, Wear, 189, (1995) 136-142.

O.N. Dogan, G. Laird II, J. A. Hawk, Abrasion Resistance of the Columnar Zone in High Cr White Cast Irons, Wear, 181–183, (1995) 342–349.

S. Turenne, F. Lavallee, J. Masounave, Matrix Microstructure Effect in the Abrasion Resistance of High Chromium White Cast Iron, J. Mater. Sci., 24, (1989), 3021–3028.

M. Durand-Charre, Microstructure of Steels and Cast Irons, Springer-Verlag, New York, 2004, p 51–73, ISBN-13:9783540209638

C.P. Tabrett, I.R. Sare, Fracture Toughness of High-Chromium White Irons: Influence of Cast Structure, J. Mater. Sci., 35, (2000), 2069–2077.

J. Asensio, J.A. Pero-Sanz, J.I. Verdeja, Microstructure Selection Criteria for Cast Irons with More Than 10 wt% Chromium for Wear Applications, Mater. Character., 49, (2003), 83–93.

G.L.F. Powell, G. Laird II, Structure, Nucleation, Growth and Morphology of Secondary Carbides in High Chromium and Cr-Ni White Irons, J. Mater. Sci., 27, (1992), 29–35.

A. Wiengmoon, T. Chairuangsri, A. Brown, R. Brydson, D.V. Edmonds, J.T.H. Pearce, Microstructural and Crystallographical Study of Carbides in 30 wt% Cr Cast Irons, Acta Mater., 53, (2005), 4143–4154.

G.L.F. Powell, J.V. Bee, Secondary Carbide Precipitation in an 18 wt% Cr-1 wt% Mo White Iron, J. Mater. Sci., 31, (1996), 707–711.

S.D. Carpenter, D. Carpenter, J.T.H. Pearce, XRD and Electron Microscope Study of a Heat Treated 26.6% Chromium White Iron Microstructure, Mater. Chem. Phys., 101, (2007), 49–55.

Jun Wang, Cong Li, Haohuai Liu, Hongshan Yang, Baoluo Shen, Shenji Gao, Sijiu Huang (2006) The Precipitation and Transformation of Secondary Carbides in a High Chromium Cast Iron. Mater Character 56: 73–78.

S.D. Carpenter, D. Carpenter, X-ray Study of M7C3 Carbide within a High Chromium White Iron, Mater. Lett., 57, (2003), 4456–4459.

J.T.H Pearce, D.W.L Elwell, Duplex Nature of Eutectic Carbides in Heat Treated 30% Chromium Cast Iron, J. Mater. Sci. Lett., 5, (1986), 1063–1064.

J.T.H Pearce, Examination of M7C3 Carbides in High Chromium Cast Iron Using Thin Foil Transmission Electron Microscopy, J. Mater. Sci. Lett., 2, (1983), 428–432.

A. Inoque, T. Masumoto, Carbide Reactions (M3C⇒M7C3⇒M23C6⇒M6C) During Tempering of Rapidly Solidified High Carbon Cr-W and Cr-Mo steels, Metall. Transact., 11A, (1980), 739–747.

A. Bedolla-Jacuinde, L. Arias, B. Hernández (2003) Kinetics of Secondary Carbide Precipitation in a High-Chromium White Iron. J Mater Eng Perform 12(4): 371–382.

A.E. Karantzalis, A. Lekatou, and H. Mavros, Microstructural Modifications of As-Cast High Chromium White Iron by Heat Treatment, J. Mater. Eng. Perform., in press (doi:10.1007/s11665-008-9285-6).

Acknowledgments

The authors would like to acknowledge the Greek Modern Castings (GMC) S.A foundry for their kind assistance in the preparation of the examined alloy. They would also like to acknowledge, Dr. Vassilios Drakopoulos, Principal Scientist of the Institute of Chemical Engineering and High Temperature Process of the Foundation of Research, Greece and Mr. Alexander Katsoulidis, Post-graduate student of the Chemistry Department of the University of Ioannina, Greece for their assistance in the SEM examination.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karantzalis, A.E., Lekatou, A. & Diavati, E. Effect of Destabilization Heat Treatments on the Microstructure of High-Chromium Cast Iron: A Microscopy Examination Approach. J. of Materi Eng and Perform 18, 1078–1085 (2009). https://doi.org/10.1007/s11665-009-9353-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-009-9353-6