Abstract

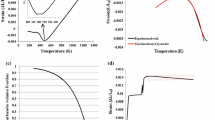

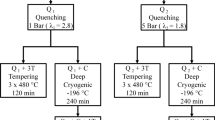

The increasing evolution of dilatometric techniques now allows for the identification of structural transformations with very low signal. The use of dilatometric techniques coupled with more common techniques, such as metallographic, hardness testing, and x-ray diffraction allows to plot a new CCT diagram for AISI M4 high-speed tool steel. This diagram is useful for a better selection of alternate solutions, hardening, and tempering heat treatments. More accurate determination of the various fields of transformation of austenite during its cooling was made. The precipitation of carbides highlighted at high temperature is at the origin of the martrensitic transformation into two stages (splitting phenomena). For slow cooling rates, it was possible to highlight the ferritic, pearlitic, and bainitic transformation.

Similar content being viewed by others

References

Technical data, Erasteel Company, Research and Development Department, Tour Maine, Montparnasse, 33 avenue du Maine, 75755 Paris Cedex 15

C. Garcia, F.G. Caballero, C. Capdevila, L.F. Alverez, Application of Dilatometric Analysis to the Study of Solid-Solid phase transformations in Steels, Mater. Character., 48, 2002, p 101–111

C. Kim, V. Biss, W.F. Hosford, A New Procedure for Determining Volume Fraction of Primary Carbides in High-Speed and Related Tool Steels, Metall. Trans. 13A, 1982, p 185

E. Bischoff, H. Opielka, I. Kabyemera, S. Karagöz, SEM-Investigation into the Quantitative Metallographical Determination of Carbides in High Speed Steels, Prakt. Metallogr., 32, 1995, p 2

R.A. Versaci, Stability of Carbides in M2 High Speed Steel, J. Mater. Sci. Lett., 7, 1988, p 273–275

G. Barreau, thèse d’etat, université de Paris Sud, Centre d’Orsay, 1982

L.A. Dobranski, Structure and Properties of High-Speed Steel with Wear Resistant Cases or Coating, J. Mater. Process. Technol., 109, 2001, p 44–51

M. Pavlickova, D. Vojech, P. Novak, J. Gemperlova, A. Gemperle, N. Zarubova, P. Lejcek, P. Jurci, P. Stolar, Thermal Treatment of PM-Tool Steel Alloyed with Niobium. Mater. Sci. Eng., A356, 2003, p 200–207

G. Delbart, A. Constant, Les Courbes de Transformation des Aciers de Fabrication Française, IRSID, France, 1974

F.G. Caballero, L.F Alvarez, C. Capdevila, C. Garcia de Andrés, The Origin of Splitting Phenomena in the Martensitic Transformation of Stainless Steels.Scripta Mater., 49, 2003, p 315–320

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Briki, J., Ben Slima, S. A New Continuous Cooling Transformation Diagram for AISI M4 High-Speed Tool Steel. J. of Materi Eng and Perform 17, 864–869 (2008). https://doi.org/10.1007/s11665-008-9238-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9238-0