Abstract

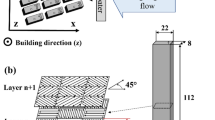

We reported the simulation and the analysis of the residual stress within the graded interlayered joints of MoSi2 to 316L stainless steel fabricated by spark plasma-sintering (SPS) technique. The residual stress in the joints was analyzed by the finite element ANSYS code. The results show that the maximum radial and axial residual tension stresses first decrease and then increase with the increase of the compositional distribution exponent (P), and consistently decrease with the increase of the number (n) and the thickness (d) of graded layer, respectively. The optimal values of compositional distribution exponent, the thickness, and the number of graded interlayered joints of the MoSi2 composite/316L are P = 0.8, d = 1.0 mm, and n = 9, respectively. The residual tension stresses in the samples treated by nine graded interlayers are reduced to 24% and 25% of those in the joints without the interlayer, respectively.

Similar content being viewed by others

References

J. Kuchino, K. Kurokawa, T. Shibayama, et al. Effect of Microstructure on Oxidation Resistance of MoSi2 Fabricated by Spark Plasma Sintering. Vacuum, 2004, 73: 623–628

P.V. Krakhmalev, E. Strom, C. Li. Microstructure and Properties Stability of Al-Alloyed MoSi2 Matrix Composites. Intermetallics, 2004, 12: 225–233

A.K. Vasudeval, J.J. Petrovic. A Comparative Overview of Molybdenum Disilicide Composites. Mater. Sci. Eng., 1992, A155: 2–3

J.J. Petrovic. Mechanical Behavior of MoSi2 and MoSi2 Composites. Mater. Sci. Eng. A, 1995, A192/A193: 31–37

S.D. Conzone, D.P. Butt, A.H. Bartlett. Joining MoSi2 to 316L Stainless Steel. J. Mater. Sci., 1997, 32: 3369–3374

M. Shinichi and T. Masato. Homogenization of Functionally Graded Materials (FGM) by Spark Plasma Sintering (SPS)[C]//NEDO International Symposium on FGM, 1999, p 183–186

R.U. Vaidya, Y.P. Rangaswam, M.A. M Bourke, et al. Measurement of Bulk Residual Stresses in Molybdenum Disilicide/Stainless Steel Joints Using Neutron Scattering. Acta Mater., 1998, 46(6): 2047–2061

Y.J. Xu, D.H. Tu, X.M. Li. Steady Thermal Stress of Functionally Gradient Material Plate Under Convective Heat Transfer Boundary. Mater. Mech. Eng., 2004, 28(7): 15–17

L.J. Zhang, Q.H. Rao, Y.H. He, et al. Research Advance on Thermal Stress of Functionally Gradient Materials. Mater. Sci. Eng. Powder Metall., 2005, 10(5): 257–262

Y. Zhang, N.S. Liu, L.Q. Chen, et al. Determination of the Physical Properties of Functional Gradient Materials. J. Solid Rocket Technol., 2004, 27(1):77–80

X.H. Zhang, W. Qu, X.Z. Zhang, et al. Optimum Design of TiC-Ni Functionally Graded Materials. Mater. Sci. Tech., 2000, 8(1):81–83

X.H. Zhang, J.C. Han, B.L. Wang, et al. Combustion Synthesis and Thermal Stress Analysis TiC-NiFGM. J. Astronautics, 2001, 22(1): 89–94

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Wu, H., Zhang, X. et al. Simulation and Analysis of Residual Stress in the Graded Interlayer of MoSi2 Composite/316L Stainless Steel Joint. J. of Materi Eng and Perform 17, 802–807 (2008). https://doi.org/10.1007/s11665-008-9226-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9226-4