Abstract

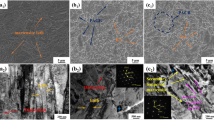

The stress corrosion cracking (SCC) behavior of two developmental nanocrystalline 5083 alloys with varied composition and processing conditions was studied. The results were compared to a commercial aluminum AA 5083 (H111) alloy. The pitting densities, size and depths, and residual tensile strengths were measured after alternate immersion in artificial seawater and atmospheric exposure under different loading conditions. Optical and scanning electron microscopy (SEM) with EDX was used to analyze the fracture surfaces of failed specimen after removal at selected intervals and tensile testing. One of the nanostructured Al-Mg alloys exhibited significantly superior pitting resistance when compared to conventional microstructured AA 5083. Under conditions where pitting corrosion showed up as local tunnels toward phase inclusions, transgranular cracking was observed, whereas under conditions when pitting corrosion evolved along grain boundaries, intergranular cracking inside the pit was observed. Pit initiation resistance of the nano alloys appears to be better than that of the conventional alloys. However, long-term pit propagation is a concern and warrants further study. The objective of this investigation was to obtain information regarding the role that ultra-fine microstructures play in their degradation in marine environments and to provide insight into the corrosion mechanisms and damage processes of these alloys.

Similar content being viewed by others

References

V. Tellkamp E. Lavernia, Processing and Mechanical Properties of Nanocrystalline 5083 Al Alloy, Nanostructured Materials, 12, 1999 pp. 249–254

U. Erb, G. Palumbo, R. Zugic, and K.T. Aust, Processing and Properties of Nanocrystalline Materials, C. Suryanarayana, Ed., TMS, 93, 1996

C. Cheung, D. Wood, and U. Erb, Processing and Properties of Nanocrystalline Materials, C. Suryanarayana, Ed., TMS, 1996, p 479–491

R.B. Inturi, Z. Szklarska-Smialowska, Localized corrosion of nanocrystalline 304 type stainless steel films, Corrosion 48,1992, pp. 398–405

O. Elkedim, H.S. Cao, P. Fluzin, Hardness and Corrosion Performance of Nanocrystalline Iron Powder Prepared by Ball Milling, Materials Sci. Forum, 312–314, 1999, pp. 635–640

W. Zieger, M. Schneider, H. Worch,” Passivity and Pitting Corrosion of a Nanocrystalline FeAl-8 Alloy,” Materials Sci. Forum, 269–272, 1998, pp.833–836

J.C. Chang, T.H. Chuang, “Stress-corrosion cracking susceptibility of the superplastically formed 5083 aluminum alloy in 3.5 pct NaCl solution,” Metall. and Mater. Trans. A, 30A, 1999, pp. 3191–3199

R. Verma, A.K. Ghosh, S. Kim, C. Kim, “ Grain Refinement and Superplasticity in 5083 Al,”Materials Sci. Eng., 191A, 1995, pp.143–156

E. Sikora, X.J. Wei, B.A. Shaw, “ Corrosion Behavior of Nanocrystalline Bulk Al-Mg-Based Alloys,” Corrosion, 60, (4), 2004, p. 387–397

ASTM G31-72, Standard Practice for Laboratory Immersion Corrosion Testing of Metals, Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, 2004, www.astm.org

ASTM G1-03, Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E8-04, Standard Test Methods for Tension Testing of Metallic Materials, Book of Standards Vol. 3.01, ASTM International, West Conshohocken, PA, www.astm.org

ASTM G44-99, Standard Practice for Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5% Sodium Chloride Solution, Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, 2005, www.astm.org

ASTM G50-76, Standard Practice for Conducting Atmospheric Corrosion Tests on Metals, Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, 2003, www.astm.org

ASTM G46-94, Standard Guide for Examination and Evaluation of Pitting Corrosion, Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, 2005, www.astm.org

ASTM G67-04, Standard Test Method for Determining the Susceptibility to Intergranular Corrosion of 5XXX Series Aluminum Alloys by Mass Loss After Exposure to Nitric Acid (NAMLT Test), Book of Standards Vol. 3.02, ASTM International, West Conshohocken, PA, www.astm.org

G.S. Chen, D.J. Harlow, and R.P. Wei, FAA/NASA, Inst. Symp. on Advanced Structure Integrity Methods for Airframe Durability and Damage Tolerance, NASA Conference Publication 3274, Langley Research Center, Hampton VA, Sept. 1994, p 157

G.S. Chen, M. Gao, R.P. Wei, “Micro-Constituents Induced Pitting Corrosion in a 2024-T3 Aluminum Alloy“ Corrosion, 52, 1996, p. 8

V. S. Sinyavskii, “ Pitting and Stress Corrosions of Aluminum Alloys; Correlation Between Them,” Protec. Of Metals, 37(5), 2001, pp. 521-530

V.L. Tellkamp, A. Melmed, E.J. Lavernia, “ Mechanical Behavior and Microstructure of Thermally Stable Bulk Nanostructured Al Alloy,” Metal and Mater Trans A, Vol. 32A, 2001, pp. 2335–2343

E. Kus, Z. Lee, S. Nutt, F. Mansfeld, “ A Comparison of the Corrosion Behavior of Nanocrystalline and Conventional Al 5083 Samples,” Corrosion, 62 (2), 2006, pp. 152–161.

C. Vanleugenhaghe, L. Klimzack-Mathieu, J. Meunier, M. Porbaix, Corros. Sci. 2, 1962, p. 69

M. Bethencourt, F.J. Botana, M.A. Cauqui, M. Marcos, M.A. Rodriguez, J.M. Rodriquez-Izquierdo,” Protection Against Corrosion in Marine Environments of AA5083 Al-Mg Alloy by Lanthanide Chlorides,” J.Alloy Comp. 250, 1997, p. 98

Witkin B.Q., Han E.J. Lavernia, “ Room-Temperature Mechanical Behavior or Cryomilled Al Alloys,” Metal and Mater Trans A, Vol.37A, 2006, pp. 185–194.

S.Y. Chang, B.D. Ahn, S.K. Hong, S. Kamado, Y. Kojima, D.H. Shin, “ Tensile Deformation Characteristics of a Nano-structured 5083 Al Alloy,” Journ. of Alloy and Comp. 386, 2005, pp. 197–201

Acknowledgments

This work was sponsored by the Office of Naval Research (ONR) grant # N00014-00-1-0153 and NACE international seed grant # N000140210024. The authors would also like to thank The LaQue Testing and Research Center for their assistance in testing and analysis, and Boeing Corporation and E. Lavernia at University of California-Irvine for providing the nanostructured alloys. Many thanks are also extended to Barbara Shaw and Ela Sikora who collaborated on this ONR project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, M., Ziemian, C.W. Pitting and Stress Corrosion Cracking Susceptibility of Nanostructured Al-Mg Alloys in Natural and Artificial Environments. J. of Materi Eng and Perform 17, 870–878 (2008). https://doi.org/10.1007/s11665-008-9215-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-008-9215-7