Abstract

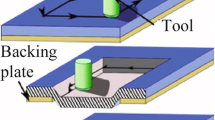

Superplastic forming (SPF) is a manufacturing process that can facilitate increased use of aluminum in automobile body structures. Despite considerable advantages with regards to formability and tooling costs, the process has been mostly limited to low volume production due to relatively long cycle times and the need to use specially processed sheet alloys. To address these issues, advanced processes such as two stage gas forming (TSGF) and hot draw mechanical pre-forming (HDMP) have been developed. Advantages of these processes have been demonstrated on the forming of a complex dash panel part. Final thickness distribution and forming time on this part manufactured with these two processes were compared to that of the same panel produced with conventional SPF. The HDMP technology which combines hot stamping with SPF was found to have the capability of forming a complex shaped component with a superior thickness profile and faster forming cycle than that formed with a conventional single stage or two stage forming cycle. Additionally, the HDMP process proved to be a robust process with a wide temperature window and allowed for the forming of lower-cost, non-spf aluminum, and magnesium sheet alloys. Finally, analysis of the post-form microstructure indicated that there was essentially no cavitation in panels formed with the HDMP process and that material with a coarse grain structure could be successfully formed.

Similar content being viewed by others

References

C.H. Hamilton and A.K. Ghosh, Superplastic Sheet Forming, Metals Handbook, 1988, p 852–869

P.A. Friedman, S.G. Luckey, and W.B. Copple, Automotive Perspectives on Superplastic Forming of Aluminum Sheet, Proc. of International Symposium on Aluminum Applications, October 13-15, 2003 (ASM Conference, Pittsburgh, PA)

S.G. Luckey, Development of Finite Element Analysis Based Tools and Methods for the Design of Advanced Superplastic Forming Dies and Processes, Ph.D. Thesis, Michigan Technological University, 2005

K. Nakamura, Manufacturing Method of Formed Product Having Required Wall Thickness by Superplastic Blow Forming Method, Patent Abstract of Japan, No. 197020, 1989

J.R. Fischer, Prethinning for Superplastic Forming, U.S. Patent Number 5,823,032, 1998

P.A. Friedman, Method and Apparatus for Superplastic Forming, U.S. Patent Number 6,581,428, 2003

Y. Luo, S.G. Luckey, P.A. Friedman, and Y. Peng, On Practical Forming Limits in Superplastic Forming of Aluminum Sheet, J. Mater. Perform. Eng., 2007, 16, p 274–283

P.A. Friedman and W.B. Copple, Superplastic Response in Al-Mg Sheet Alloys, J. Mater. Eng. Perform., 2004, 13, p 335–347

Y. Luo, S.G. Luckey, P.A. Friedman, and Y. Peng, Finite Element Analysis of an Advanced Superplastic Forming Process Utilizing a Mechanical Pre-form, SAE 2007-01-1676

S.G. Luckey, P.A. Friedman, and K.J. Weinmann, Correlation of Finite Element Analysis to Superplastic Forming Experiments, J. Mater. Process. Technol., 2007, 194, p 30–37

Acknowledgments

The authors would like to acknowledge the assistance of Pete Jolley and Ken Kendall of Aston Martin for their help in identifying the production panel used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was presented at the AeroMat Conference, International Symposium on Superplasticity and Superplastic Forming (SPF) held in Baltimore, MD, June 25-28, 2007.

Rights and permissions

About this article

Cite this article

Luo, Y., Luckey, S., Copple, W. et al. Comparison of Advanced SPF Die Technologies in the Forming of a Production Panel. J. of Materi Eng and Perform 17, 142–152 (2008). https://doi.org/10.1007/s11665-007-9176-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9176-2