Abstract

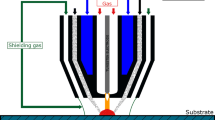

Among advanced manufacturing processes of metal matrix composite parts, thixoforging is one of the most effective forming processes. The investigation of this research article is to provide the proper conditions such as the die shape, the forging velocity, the forging time, the forging pressure, and reinforcement content in the thixoforming process for fabricating hollow shape parts. To investigate the effect of injection velocity and pressure on various defects in thixoforged cylinder liners, filling tests were performed by MAGMA S/W. In order to evaluate the effectiveness of calculated conditions, which are given by computer-aided engineering, A380 and SiCp/A380 cylinder liners were fabricated under the calculated conditions. SiCp/A380 composite billets were fabricated by both the mechanical stirring and electro-magnetic stirring processes. In the case of SiCp/A380 composite cylinder liners, the effect of reinforcement (SiCp) distribution, content (10-20 vol.%) and size (5.5-14 μm) on the mechanical properties was investigated.

Similar content being viewed by others

References

P.C. Cox, G.G. McGrath, and G.M. Savage, “Designing with Reinforced Composites to Provide Energy Absorption Mechanisma in Damage Formula 1 Cars,” Proc. of the 9th Int. Conf. on Composite Materials, Vol 6, Madrid, Antonio Miravete, 12–16 July, 1993, p 241–251

J.J. Manso, “Continous Process of Structural Frames for Automotive Applications,” Proc. of the 9th Int. Conf. on Composite Materials, Vol 6, Madrid, Antonio Miravete, 12–16 July, 1993, p 276–282

J.A. Cornie, H.K. Moon, and M.C. Flemings, “A Review of Semi-Solid Slurry Processing of Al-Matrix Composites,” Proc. of the 8th Int. Conf. on Composite Materials, Vol 4, Montreal Quebec, Canada, 17–29 Sep, 1990, p 63–78

F.A. Girot, L. Albingre, J.M. Quenisset, and R. Naslain, Rheocasting Al Matrix Composties, J. Mater. Proc. Technol., Nov. 1987, pp.18–21

S. Caron and J. Masounave, “A Literature Review on Fabrication Techniques of Particulates Reinforced Metal Composites,” Proc. of the 8th Int. Conf. on Composite Materials, Vol 3, Montreal Quebec, 17–29 Sep, 1990, p 79–86

Y. Morita, K. Ozawa, Y. Ando, S. Yahata, and A. Nanba, “Compocasting Conditions and Mechanical Properties of Aluminum Matrix Composite Reinforced by SiC Particles,” Proc. 3rd Int. Conf. on Semi-Solid Processing of Alloy and Composite, Institute of Industrial Science University of Tokyo, Japan, Manabu Kiuchi, 13–15 June, 1994, p 39–1 to 39–11

D.G. Lee, C.G. Kang (2001) Investigation of Reinforced Distribution in Fabrication Process of Metal Matrix Composites by Combined Stirring Process. J. Korean Soc. Comp. Mater. 14(15): 1–11

D.G. Lee, C.G. Kang (2002) Reheating Process of Metal Matrix Composites Fabricated by Combined Stirring Process for Thixoforming. Trans. Mater. Proc. 11(1): 45–53

J.C. Heo, C.G. Kang (2001) Digital Manufacturing Technology for Thixocasting of Particulate Reinforced Metal Matrix Composites with Pipe Shape. J. Korean Foundrymen’s Soc. 21(6): 311–321

J.J. Valencia, T.G. Friedhoff, T.P. Creeden, and J.J. Cardarella, “Microstructural Evaluation of Rapidly Heated Aluminium A356 Alloy Billets,” Proc. 5th. Intl. Conf. On Semi-Solid Processing of Alloys and Composites, Colorado School of Mines, Colorado, 23–25 June, 1998, p 397–404

S.S. Ahn, C.G. Kang, and H.H. Jo, “Induction Heating of Metal Matrix Composites for Thixoforming,” 2nd Asia-Australian Conf. on Composites Materials (ACCM-2000), Kyongju, Korea, 18–20 Aug, 2000, p 309–314

C.G. Kang, S.W. Youn, P.K. Seo (2002) Reheating Process of Metal Matrix Composites for Thixoforming and Their Inductive Coil Design. J. Mater. Eng. Perform. 11(2): 152–165

N.S. Kim, C.G. Kang (2000) An Investigation of Flow Characteristics Considering the Effect of Viscosity Variation in the Thixoforming Process. J. Mater. Proc. Technol. 103: 12–23

C.G. Kang S.W. Youn P.K. Seo (2003) Fabrication of SiCp/Al Composite Billets by Horizontal Continuous casting and their Mechanical Properties. Key Eng. Mater. 233–236: 679–684

A.R.A. Mchelland, H.V. Atkinson, P. Kapranos, D.H. Kirkwood (1991) Thixoforming Spray Aluminum/Silicon Carbide MMCs. Mater. Lett. 11: 26–30

Acknowledgments

This work was supported by the Korea Science and Engineering Foundation (KOSEF) through grants-in-sid for the National Core Research Center Program (NCRC) from MOST/KOSEF (NO. R15-2006-022-02001-0).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, K., Lee, S. & Kang, C. Two-phase Flow Characteristics in Hollow Shape Fabrication Process of Metal Matrix Composites by Thixoforging. J. of Materi Eng and Perform 17, 432–444 (2008). https://doi.org/10.1007/s11665-007-9159-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9159-3