Abstract

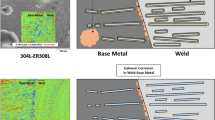

Welding plays an essential role in fabrication of components such as boiler drum, pipe work, heat exchangers, etc., used in power plants. Gas tungsten arc welding (GTAW) is mainly used for welding of boiler components. Pulsed GTAW is another process widely used where high quality and precision welds are required. In all arc-welding processes, the intense heat produced by the arc and the associated local heating and cooling lead to varied corrosion behavior and several metallurgical phase changes. Since the occurrence of corrosion is due to electrochemical potential gradient developed in the adjacent site of a weld metal, it is proposed to study the effects of welding on the corrosion behavior of these steels. This paper describes the experimental work carried out to evaluate and compare corrosion and its inhibition in SA 516 Gr.70 carbon steel by pulsed GTAW process in HCl medium at 0.1, 0.5, and 1.0 M concentrations. The parent metal, weld metal and heat affected zone are chosen as regions of exposure for the study made at room temperature (R.T.) and at 100 °C. Electrochemical polarization techniques such as Tafel line extrapolation (Tafel), linear polarization resistance (LPR), and ac impedance method have been used to measure the corrosion current. The role of hexamine and mixed inhibitor (thiourea + hexamine in 0.5 M HCl), each at 100 ppm concentration is studied in these experiments. Microstructural observation, surface characterization, and morphology using SEM and XRD studies have been made on samples exposed at 100 °C in order to highlight the nature and extent of film formation.

Similar content being viewed by others

References

R.L.O. Brien, Welding Processes, Welding Handbook, Vol. 2, 8th ed., AWS, Miami, Florida, USA,1995

T.G. Gooch, The Effect of Welding on Corrosion, Process Industry Corrosion – Theory and Practice, NACE Publication, 1982, p 739–755

M. Henthorne, (1974) Corrosion Testing of Weldments. Corrosion – NACE 30:39

G.E. Linnert, Welding Metallurgy, Carbon and Alloy Steels, Vol. 1, 4th ed., AWS, Miami, Florida, USA, 1994

G.S. Theus and P.L. Daniel, Corrosion in Power Generating Equipment, Proc. 8th International Brown Boveri Symposium (Baden, Switzerland), 1983, p 185–188

NACE, Corrosion Testing of Chemical Cleaning Solvents, NACE Publication 3M, Mater. Perform. 21, 1982, p 48

A.N. Rothwell (1992) Weld Corrosion: Causes and Solutions. J. Corros. Prevent. Control 39(5):113–118

S. Natarajan, “Studies on Corrosion Behaviour of Boiler Steel Weldments in Acid Medium,” Ph.D. Thesis, Bharathidasan University, Tiruchirapalli, India, 1990

P.J. Antony, S. Natarajan, R. Vaideeswaran (2003) Corrosion and its Inhibition in the Carbon Steel Induction-Pressure Weldments used in Power Plants. J. Corros. Prevent. Control 50(4):181–188

Natarajan S., Sivan V. (2003) High Temperature Corrosion and its Inhibition in Carbon Steel Fusion Weldments used in Power and Process Plants. Int. J. Join. Mater. 15(3):17–23

S. Kou, Welding Metallurgy, 2nd ed., John Wiley & Sons, 2003

S.P. Kumaresh Babu and S. Natarajan, Influence of Heat Input on Corrosion Behaviour of FCA Weldments in Power Plant Carbon Steel, Proc. of International Conference, Chennai, NACE, CORCON-2005, 2005

S. Natarajan, V. Sivan (2003) Weldment Corrosion and its Control in Power Generating Components. J. Corros. Prevent. Control 50(1):7–19

S.P. Kumaresh Babu and S. Natarajan, Corrrosion Behaviour of Flux Cored Arc Weldments in Carbon Steel Used in Power Plants, J. STEEL-GRIPS, 2006, 4(3), p 207–211

G.M.W. Mann (1977) History and Causes of On-Load Water Side Corrosion in Power Boilers. Br. Corros. J. 12(1):6–13

D. Jones, Principles and Prevention of Corrosion, 2nd ed., Prentice Hall of India, 1996

L. Kayafas, Corrosion Product Removal from Steel Fracture Surfaces for Metallographic Examination, J. Corros., 25, 1990, p 443

P. Mayer and A.V. Manolesu, Growth and Structure of Indigenous Magnetite on Boiler Tubes, Proc.7th ICMC (Ontaria, Canada), Trans Tech Publications Inc., 1980, p 1480–1487

W.M.M. Huijbregts, Protection Effectiveness of Magnetite Layers in Relation to Boiler Corrosion, 5th ICMC (Tokyo), Trans Tech Publications Inc., 1972, p 857

P.H. Effertz, Morphology and Composition of Magnetite Layers in Boiler Tubes Following Long Exposure, Proc. 5th ICMC (Tokyo, Japan), Trans Tech Publications Inc., 1972, p 920

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumaresh Babu, S., Natarajan, S. Corrosion Behavior of Pulsed Gas Tungsten Arc Weldments in Power Plant Carbon Steel. J. of Materi Eng and Perform 16, 620–625 (2007). https://doi.org/10.1007/s11665-007-9118-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9118-z