Abstract

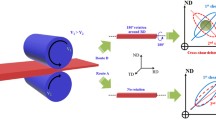

A new rolling process, so-called as equal channel angular rolling (ECAR) process, for fabricating the magnesium alloy sheets with an enhanced formability at room temperature is introduced. The ECAR device was designed so that it could feed the sheet with the preheated temperature of 673 K in a continuous manner at a relatively high speed of 0.43 m/s. A significant amount of the shear deformation could be achieved by passing the sheet through the mold with the oblique angle of 115°. The x-Ray spectra were examined to analyze the crystal orientation of the sheets, which indicates that the crystal orientation with non-basal plane was fabricated after ECAR processing. The grain was not refined and plenty of twins were brought out because of the low-shear deforming temperature. The high stress and low ductility for the ECARed specimens can be related to the presence of twins. In spite of having the similar optical microstructure, the elongation to failure for the ECARed specimens after annealing was above 33%, which was larger than that of about 20% for the as-received/annealed specimens. And the drawability for the ECARed/annealed specimens with the Erichsen value of 6.24 mm and the limiting drawing ratio of 1.6 can be obtained, which is improved dramatically than that of 4.18 mm and 1.2 for the as-received/annealed specimens, respectively. These can be related to the rotation of (0002) basal plane toward the rolling direction because of the shear deformation induced by ECAR process.

Similar content being viewed by others

References

Shoichiro Y., Hisashi N., Hirokuni Y., Manabe K. (2003) Formability Enhancement in Magnesium Alloy Stamping using a Local Heating and Cooling Technique: Circular Cup Deep Drawing Process. J. Mater. Processing Technol. 142(3):609–613

Chen F.K., Huang T.B., Chang C.K. (2003) Deep Drawing of Square Cups with Magnesium Alloy AZ31 Sheets. Int. J. Machine Tools Manufacture 43(15):1553–1559

Chang T.C., Wang J.Y., Ming O.C., Lee S. (2003) Grain Refining of Magnesium Alloy AZ31 by Rolling. J. Mater. Processing Technol. 140:588–591

Pérez-Prado M.T., del Valle J.A., Ruano O.A. (2005) Achieving High Strength in Commercial Mg Cast Alloys Through Large Strain Rolling. Mater. Lett. 59:3299–3303

Q.L. Zhang, C. Lu, Y.P. Zhu, and W.J. Ding, 轧 制 方 式 对 AZ31 镁合金薄板组织和性能的影响 (Effect of Rolling Method on Microstructure and Properties of AZ31 Magnesium Alloy thin Sheet). Chin. J. Nonferrous Metals, 2004, 14(3), p 391–397 (in Chinese)

Iwanaga K., Tashiro H., Okamoto H., Shimizu K. (2004) Improvement of Formability from Room Temperature to Warm Temperature in AZ-31 Magnesium Alloy. J. Mater. Processing Technol. 155–156:1313–1316

Mukai T., Yamanoi M., Watanabe H., Higashi K. (2001) Ductility Enhancement in AZ31 Magnesium Alloy by Controlling its Grain Structure. Scripta Mater. 45:89–94

Agnew S.R., Horton J.A., Lillo T.M., Brown D.W. (2004) Enhanced Ductility in Strongly Textured Magnesium Produced by Equal Channel Angular Processing. Scripta Mater. 50:377–381

Koike J. (2003) New Deformation Mechanisms in Fine-Grain Mg Alloys. Mater. Sci. Forum 419–422:189–194

Kim W.J., Hong S.I., Kim Y.S., Min S.H., Jeong H.T., Lee J.D. (2003) Texture Development and Its Effect on Mechanical Properties of an AZ61 Mg Alloy Fabricated by Equal Channel Angular Pressing. Acta Mater. 51:3293–3307

J.A. del Valle, F. Carreño, and O.A. Ruano, Influence of Texture and Grain Size on Work Hardening and Ductility in Magnesium-based Alloys Processed by ECAP and Rolling. Acta Mater., 2006, 54, p 4247–4259

Yoshida Y., Cisar L., Kamado S., Kojimo Y. (2003) Effect of Microstructural Factors on Tensile Properties of an ECAE-Processed AZ31 Magnesium Alloy. Materialia Transaction 44(4):468–475

Kim H.K., Kim W.J. (2004) Microstructural Instability and Strength of an AZ31 Mg Alloy after Severe Plastic Deformation. Mater. Sci. Eng. A385:300–308

Watanbe H., Mukai T., Ishikawa K. (2004) Differential Speed Rolling of an AZ31 Magnesium Alloy and the Resulting Mechanical Properties. J. Mater. Sci. 39:1477–1480

Kim S.H., You B.S., Yim C.D., Seo Y.M. (2005) Texture and Microstructure Changes in Asymmetrically Hot Rolled AZ31 Magnesium Alloy Sheets. Mater. Lett. 59:3876–3880

Chino Y., Mabuchi M., Kishihara R., Hosokawa H., Yamada Y., Wen C.E., Shimojima K., Iwasaki H. (2002) Mechanical Properties and Press Formability at Room Temperature of AZ31 Mg Alloy Processed by Single Roller Drive Rolling. Mater. Trans. 43(10):2554–2560

Saito Y., Utsunomiya H., Suzuki H. (2000) Improvement in the r-value of Aluminum Strip by a Continuous Shear Deformation Process. Scripta Mater. 42:1139–1144

Utsunomiya H., Hatsuda K., Sakai T., Saito Y. (2004) Continuous Grain Refinement of Aluminum Strip by Conshearing. Mater. Sci. Eng. A372:199–206

Lee J.C., Seok H.K., Han J.H., Chung Y.H. (2001) Controlling the Textures of the Metal Strips via the Continuous Confined Strip Shearing (C2S2) Process. Mater. Res. Bull. 36:997–1004

Lee J.C., Seok H.K., Suh J.Y. (2002) Microstructural Evolutions of the Al Strip Prepared by Cold Rolling and Continuous Equal Channel Angular Pressing. Acta Mater., 50:4005–4019

Nam C.Y., Han J.H., Chung Y.H., Shin M.C. (2003) Effect of Precipitates on Microstructural Evolution of 7050 Al Alloy Sheet During Equal Channel Angular Rolling. Mater. Sci. Eng. A347:253–257

Park J.W., Kim J.W., Chung Y.H. (2004) Grain Refinement of Steel Plate by Continuous Equal-Channel Angular Process. Scripta Mater. 51:181–184

Y.Q. Cheng, Z.H. Chen, W.J. Xia, and D.F. Fu, 等径角轧制 AZ31 镁合金板材组织与性能研究 (Microstructures and Mechanical Properties of AZ31 Magnesium Alloy Sheet Processed by Equal Channel Angular Rolling), Chin. J. Nonferrous Metals, 2005, 15(9), p 1369–1375 (in Chinese)

Z.H. Chen, Y.Q. Cheng, and W.J. Xia, Effect of Equal Channel Angular Rolling Pass on Microstructure and Properties of Magnesium Alloy Sheets. Mater. Manufacturing Processes, 2007, 22, p 51–56

Luis Pérez C.J. (2004) On the Correct Selection of the Channel Die in ECAP Processes. Scripta Mater. 50:387–393

Iwahashi Y., Wang J.T., Horita Z., Nemoto M., Langdon T.G. (1996) Principle of Equal-Channel Angular Pressing for the Processing of Ultra-fine Grained Materials. Scripta Mater. 35(2):143–146

Yoshida Y., Cisar L., Kamado S., Koike J., Kojima Y. (2003) Texture Development of AZ31 Magnesium Alloy during ECAE Processing. Mater. Sci. Forum 419–422:533–538

Pérez-Prado M.T., Ruano O.A. (2002) Texture Evolution During Annealing of Magnesium AZ31 Alloy. Scripta Mater. 46:149–155

Yang P., Cui F., Ma S.C., Gottstein G. (2003) Influence of Initial Textures on Dynamic Recrystallization and Textures in AZ31 Magnesium Alloys. Trans. Nonferrous Met. Soc. China 13(3):504–508

Couret A., Cailiard D. (1985) An in situ Study of Prismatic Glide in Magnesium – I. The Rate Controlling Mechanism. Acta Metal. 33(8):1447–1454

Koike J., Ohyama R., Kobayashi T., Suzuki M., Maruyama K. (2003) Grain-boundary Sliding in AZ31 Magnesium Alloys at Room Temperature to 523 K. Mater. Trans. 44(4):445–451

Wagener H.W., Hartmann J.H., Reinhard F. (2003) Deep Drawing and Impact Extrusion of Magnesium Alloys at Room Temperature. Adv. Eng. Mater. 5(4):237–242

Y. Q. Cheng, Z.H. Chen, and W.J. Xia, Drawability of AZ31 Magnesium Alloy Sheet Produced by Equal Channel Angular Rolling at Room Temperature. Mater. Charact., 2007, 58, p 617–622

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, Y.Q., Chen, Z.H., Xia, W.J. et al. Improvement of Drawability at Room Temperature in AZ31 Magnesium Alloy Sheets Processed by Equal Channel Angular Rolling. J. of Materi Eng and Perform 17, 15–19 (2008). https://doi.org/10.1007/s11665-007-9103-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9103-6