Abstract

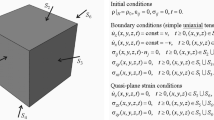

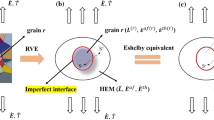

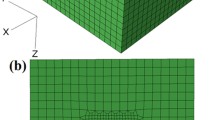

A finite element method was recently designed to model the mechanisms that cause superplastic deformation (A.F. Bower and E. Wininger, A Two-Dimensional Finite Element Method for Simulating the Constitutive Response and Microstructure of Polycrystals during High-Temperature Plastic Deformation, J. Mech. Phys. Solids, 2004, 52, p 1289–1317). The computations idealize the solid as a collection of two-dimensional grains, separated by sharp grain boundaries. The grains may deform plastically by thermally activated dislocation motion, which is modeled using a conventional crystal plasticity law. The solid may also deform by sliding on the grain boundaries, or by stress-driven diffusion of atoms along grain boundaries. The governing equations are solved using a finite element method, which includes a front-tracking procedure to monitor the evolution of the grain boundaries and surfaces in the solid. The goal of this article is to validate these computations by systematically comparing numerical predictions to experimental measurements of the elevated-temperature response of aluminum alloy AA5083 (M.-A. Kulas, W.P. Green, E.M. Taleff, P.E. Krajewski, and T.R. McNelley, Deformation Mechanisms in Superplastic AA5083 materials. Metall. Mater. Trans. A, 2005, 36(5), p 1249–1261). The experimental work revealed that a transition occurs from grain-boundary sliding to dislocation (solute-drag) creep at approximately 0.001/s for temperatures between 425 and 500 °C. In addition, increasing the grain size from 7 to 10 μm decreased the transition to significantly lower strain rates. Predictions from the finite element method accurately predict the effect of grain size on the transition in deformation mechanisms.

Similar content being viewed by others

References

Barnes A.J. (1994) Superplastic Forming of Aluminum Alloys. Mater. Sci. Forum 170–172:701–714

J.G. Schroth, “General Motors Quick Plastic Forming process,” Advances in Superplasticity and Superplastic Forming, E.M. Taleff, P.A. Friedman, P.E. Krajewski, R.S. Mishra, and J.G. Schroth, Eds., TMS, 2004, p 9–20

Verma R., Ghosh A.K., Kim S., Kim C. (1995) Grain Refinement and Superplasticity in 5083 Al. Mater. Sci. Eng. A191:143–150

Verma R., Friedman P.A., Ghosh A.K., Kim S., Kim C. (1996) Characterization of Superplastic Deformation Behavior of a Fine Grain 5083 Al Alloy Sheet. Metall. Mater. Trans. A 27A:1889–1898

Khaleel M.A., Smith M.T., Pitman S.G. (1997) The Effect of Strain Rate History on the Ductility in Superplastic AA-5083. Scripta Mater. 37(12):1909–1915

Iwasaki H., Hosokawa H., Mori T., Tagata T., Higashi K. (1998) Quantitative Assessment of Superplastic Deformation Behavior in a Commercial 5083 Alloy. Mat. Sci. Eng. A. A252:199–202

Patankar S.N., Jen T.M. (1998) Strain Rate Insensitive Plasticity in Aluminum Alloy 5083. Scripta Mater. 38(8):1255–1261

Hsiao I.C., Huang J.C. (1999) Development of Low Temperature Superplasticity in Commercial 5083 Al-Mg Alloys. Scripta Mater. 40(6):697–703

Martin C.F., Blandin J.J., Salvo L. (2001) Variations in Microstructure and Texture during High Temperature Deformation of Al–Mg Alloy. Mater. Sci. Eng. A 297:212–222

Cleveland R.M., Ghosh A.K., Bradley J.R. (2003) Comparison of Superplastic Behavior in Two 5083 Aluminum Alloys. Mater. Sci. Eng. A. A351(1–2):228–236

Sherby O.D., Wadsworth J. (1989) Superplasticity-Recent Advances and Future Directions. Prog. Mater. Sci. 33:169–221

Kulas M.-A., Green W.P., Taleff E.M., Krajewski P.E., McNelley T.R. (2005) Deformation Mechanisms in Superplastic AA5083 materials. Metall. Mater. Trans. A 36(5):1249–1261

Agarwal S., Krajewski P.E., Briant C.L. (2004) Texture Development and Dynamic Recrystallization in AA5083 during Superplastic Forming at Various Strain Rates. Taleff E.M., Friedman P.A., Krajewski P.E., Mishra R.S., Schroth J.G. (eds) Advances in Superplasticity and Superplastic Forming, Charlotte, TMS, p 95–108

Bower A.F., Wininger E. (2004) A Two-Dimensional Finite Element Method for Simulating the Constitutive Response and Microstructure of Polycrystals during High-Temperature Plastic Deformation. J. Mech. Phys. Solids 52:1289–1317

Pierce D., Asaro R.J., Needleman A. (1983) Material Rate Dependence and Localized Deformation in Crystalline Solids. Acta Metall. 31:1951–1976

H. Frost, M.F. Ashby, Deformation Mechanism Maps, 1st ed., Chap. 4, Pergamon Press, 1982, p 20–29

Raj R., Ashby M.F. (1971) On Grain Boundary Sliding and Diffusion Creep. Metal. Trans. 2(4):1113–1127

Acknowledgments

This work was performed as part of the General Motors Collaborative Research Laboratory on Computational Materials Research at Brown University. Research at The University of Texas was funded by General Motors.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article was presented at the AeroMat Conference, International Symposium on Superplasticity and Superplastic Forming (SPF) held in Seattle, WA, June 6–9, 2005.

Rights and permissions

About this article

Cite this article

Agarwal, S., Briant, C.L., Krajewski, P.E. et al. Experimental Validation of Two-dimensional Finite Element Method for Simulating Constitutive Response of Polycrystals During High Temperature Plastic Deformation. J. of Materi Eng and Perform 16, 170–178 (2007). https://doi.org/10.1007/s11665-007-9028-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-007-9028-0