Abstract

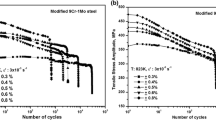

This study investigates discrepancies regarding cyclic softening of Cu processed by severe plastic deformation (SPD). All samples softened if the microhardnesses before and after fatiguing are compared. However, the effect decreases if the strain amplitude is small, Δεp <1 × 10−3). Samples with equiaxed subgrains were more resistant to softening and thermal recovery. All samples had “persistent” shear bands except those tested at the highest amplitudes, Δεp >1 × 10−2. Cu processed by SPD exhibits an enhanced fatigue life at low amplitudes. However, low thermal stability, potential for softening, and poor low-cycle properties discredit this advantage.

Similar content being viewed by others

References

J.R. Weertman, D. Farkas, K. Hernker, H. Kung, M. Mayo, R. Mitra, and H. Van Swygenhoven, MRS Bulletin 24, 44 (1999).

R.W. Seigel and G.E. Fouger, Nanostruct. Mater. 5, 205 (1995).

R.Z. Valiev, F. Chmelik, F. Bordeaux, G. Kapelski, and B. Baudelet, Scripta Metall. Mater. 27, 855 (1992).

A.B. Witney, P. G. Sanders, J. R. Weertman, and J. A. Eastman, Scripta Metal. 33, 2025 (1995).

A. Vinogradov, Y. Kaneko, K. Kitagawa, S. Hashimoto, V. Stolyarov, and R. Valiev, Scripta Mater. 36, 1345 (1997).

S.R. Agnew and J.R. Weertman, Mater. Sci. Eng. A244, 145 (1998).

J. Morrow, Internal Friction, Damping, and Cyclic Plasticity, ASTM STP 378, (Philadelphia, PA: ASTM, 1965), pp. 48–87).

C.E. Feltner and C. Laird, Acta Metall. 15, 1621 (1967).

C.E. Feltner and C. Laird, Acta Metall. 15, 1633 (1967).

G.E. Dieter, Mechanical Metallurgy, 3d ed. (New York: McGraw-Hill, 1986), p. 290.

A. Vinogradov, Y. Kaneko, K. Kitagawa, S. Hashimoto, and R. Valiev, Materials Forum 269–272, 987 (1998).

J. Polák, K. Obrtlík, M. Hájek, and A. Vašek, Mat. Sci. Eng. A151, 19 (1992).

J. Polák and M. Klesnil, Mat. Sci. Eng. 63, 189 (1984).

V.M. Segal, V.I. Reznikov, A.E. Drobyshevskiy, and V.I. Kopylov, Russian Metallurgy (English trans.) 1, 115 (1981).

V.M. Segal, Mat. Sci. Eng. A197, 157 (1995).

R.Z. Valiev, N.A. Krasilnikov, and N.K. Tsenev, Mat. Sci. Eng. A137, 35 (1991).

V.M. Segal, R.E. Goforth, and K.T. Hartwig, U.S. Patent 5,400,633 (1995).

A. Abel, Materials Forum 10, 11 (1987).

A. Abel, Mat. Sci. & Eng. 36, 117 (1978).

A. Abel, M. Wilhelm, and V. Gerold, Mat. Sci. Eng. 37, 187 (1979).

Y. Iwanishi, Z. Horita, M. Nemoto, and T. Langdon, Acta Mater. 46, 3317 (1998).

R.Z. Valiev, E.V. Kozlov, Yu.F. Ivanov, J. Lian, A.A. Nazarov, and B. Baudelet, Acta Metall. 42, 2467 (1994).

S.R. Agnew, U.F. Kocks, K.T. Hartwig, and J.R. Weertman, Proc. 19th Risø Inter. Symp. Mater. Sci., ed. J.V. Carstensen et al. (1998), p. 201.

P. Lukas and L. Kunz, Mater. Sci. Eng. 85, 67 (1987).

A.W. Tompson and W.A. Backofen, Acta Metall. 19, 597 (1971).

J.F. Tavernelli and L.F. Coffin, Trans. ASME 51, 483 (1959).

S.R. Agnew, Ph.D. thesis, Northwestern University (1998).

H. Shirai, Ph.D. thesis, Northwestern University (1984).

Sh.Kh. Khannanov, Phys. Met. Metallogr. 82, 263 (1996).

Y.J.M. Bruchet, Key Eng. Mater. 103, 21 (1995).

M. Zaiser, M. Avlonitis, and E.C. Aifantis, Acta Mater. 46, 4143 (1998).

M.V. Glazov and C. Laird, Acta Metall. Mater. 43, 2849 (1995).

T. Ogura, K. Fukushirna, and T. Masumoto, Scripta Metall. 9, 979 (1975).

T. Ogura, K. Fukushima, and T. Masumoto, Mat. Sci. Eng. 23, 2029 (1976).

H.S. Chen, Mater. Sci. Eng. 25, 59 (1976).

C.A. Pampillo and H.S. Chen, Mater. Sci. Eng. 13, 181 (1974).

J.E. Carsley, W.W. Milligan, S.A. Hackney, and E.C. Aifantis, Metall. Mater. Trans. A26, 2479 (1995).

X.H. Zhu, J.E. Carsley, W.W. Milligan, and E.C. Aifantis, Scripta Mater. 36, 721 (1997).

J.E. Carsley, W.W. Milligan, X.H. ZhLi, and E.C. Aifantis, Scripta Mater. 36, 727 (1997).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Agnew, S.R., Vinogradov, A.Y., Hashimoto, S. et al. Overview of fatigue performance of Cu processed by severe plastic deformation. J. Electron. Mater. 28, 1038–1044 (1999). https://doi.org/10.1007/s11664-999-0181-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-999-0181-0