Abstract

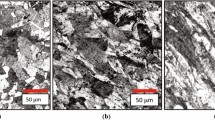

Stress relaxation and creep of the electrodeposited and rolled copper foils, 12-35 μm thick, are investigated near yield stress and near room temperature. The stress relaxation does not obey a logarithmic time law; the creep appears to follow a power function. These deviations from the expected logarithmic behavior are thought to be caused by very small grain size, unstable non-equilibrium defect structure and extensive micropore population (vacancies and vacancy clusters) typical of the electrodeposit. Relaxation and creep are significantly lower for the rolled (than for the electrodeposited) foil. Decreasing the electrode-posit thickness has an effect of enhancing relaxation and creep, attributable to a limited nucleation on the cathode surface and consequent generation of microvoids between growth clusters in the vicinity of the substrate. The foil thickness effect on creep and stress relaxation is not observed for the rolled foil, which is prone to embrittlement and stiffening at about 323K.

Similar content being viewed by others

References

A. Fox, J. Testing Evaluation 4, 74 (1976).

L.A. Tumanova and T.D. Shermergor, Phys. Met. Metall. 34 (4), 207 (1972).

L.A. Tumanova and T.D. Shermergor, Phys. Met. Metall. 48 (3), 172 (1979).

I.T. Aleksanyan, Phys. Met. Metall. 25 (5), 189 (1968).

V.l. Verbkina, K.K. Ziling and L.D. Pokrovskiy, Phys. Met. Metall. 39 (5), 1086 (1975).

L.S. Palatnikand A.I.Il’inskii,Sov.Phys. Usp. 11,564(1969).

F.R. Brotzen, Inter. Mater. Rev. 39, 24 (1994).

A.I. Il’inskii, L.S. Palatnik and N.P. Sapelkin, Sov. Phys. Solid State 15, 2134 (1974).

H.D. Merchant, Defect Structure. Morphology and Properties of Deposits, ed. Harish D. Merchant, (Warrendale, PA: TMS, 1995), p. 1.

M.Y. Fuks, L.S. Palatnik, A.I. Il’inskii and V.V. Belozerov, Sov. Phys. Solid State 9, 588 (1967).

K.K. Ziling and V. Y. Pchelkin , Zh. Prikl. Mekh. Tekh. Fiz. (3), 442 (1970).

I.I. Solonovich, Phys. Met. Metall. 40 (3), 158 (1975).

F.R. Brotzen, CT. Rosenmayer, CG. Cofer and R.J. Gale, Vacuum 41, 1287 (1990).

R.J. DeAngelis, D.B. Knorr and H.D. Merchant, J. Electron. Mater. 24, 927 (1995).

H.D. Merchant, J. Electron. Mater. 22, 631 (1993).

T.R. Bergstresser and H.D. Merchant, Defect Structure, Morphology and Properties of Deposits, ed. Harish D. Merchant, (Warrendale, PA: TMS, 1995), p. 115.

T.G. Nieh and W.D. Nix, Metall. Trans. A 12A, 893 (1981).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Merchant, H.D. Stress relaxation and creep of 12 to 35 μm copper foil. J. Electron. Mater. 26, 833–838 (1997). https://doi.org/10.1007/s11664-997-0259-5

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/s11664-997-0259-5