Abstract

Nano-Ag paste sintering has attracted much attention for high-power electronics packaging owing to its excellent electrical conductivity, thermal conductivity, and oxidation resistance. However, it requires printing and pre-heating before the die attach process, and the organics in the paste do not evaporate easily for large-area die attachment. In this work, a nano-Ag film (~ 100 μm thickness) with only 2.1% organics is developed to realize low-temperature bonding, which is compatible with the current sintering bonding process. The optimized preparation parameters of the nano-Ag films was optimized as 180°C-5 min. The characteristics and sintering mechanism of nano-Ag film are discussed. The results showed that the micro/nanostructure on the surface of nano-Ag film with a small amount of organic material is responsible for the low-temperature sintering ability, which realized 24.01 MPa shear strength at 200°C. The fracture was analyzed and failure modes are discussed. The easy-to-use features and low-temperature sintering ability make the nano-Ag film a promising die-attach material with high reliability.

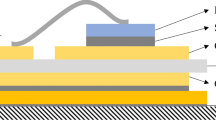

Graphical Abstract

Similar content being viewed by others

References

S.R. Esa, G. Omar, S.H. Sheikh, M. Fadzullah, and B. Out, Diffusion mechanism of silver particles in polymer binder for die attach interconnect technology. Int. J. Nanoelectron. M. 13, 461–472 (2020).

H. Zhang, H. Zhang, Q. Jia, C. Yin, Z. Deng, W. Guo, and Z. Wan, Novel SiC-based power device bonding materials of nano foam sheet and its characteristic and properties. IEEE T Electron. Pack. (2023). https://doi.org/10.1109/tcpmt.2023.3288389.

Lei, G. Thermomechanical reliability of low-temperature sintered attachments on direct bonded aluminum (DBA) substrate for high-temperature electronics packaging. Virginia Tech, (2010).

G. Qu, Z. Deng, W. Guo, Z. Peng, Q. Jia, E. Deng, and H. Zhang, The heat-dissipation sintered interface of power chip and heat sink and its high-temperature thermal analysis. IEEE T. Electron. Pack. (2023). https://doi.org/10.1109/tcpmt.2023.3290303.

C.M. Chen, K.J. Wang, and K.C. Chen, Isothermal solid-state aging of Pb-5Sn solder bump on Ni/Cu/Ti under bump metallization. J. Alloy. Compd. 432, 122–128 (2007). https://doi.org/10.1016/j.jallcom.2006.05.116.

Z. Zheng, C. Chen, Y. Yang, Z. Hao, and K. Suganuma, Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J. Alloy. Compd. 18, 34383 (2018). https://doi.org/10.1016/j.jallcom.2018.11.251.

R.W. Johnson, J.L. Evans, P. Jacobsen, J. Thompson, and M. Christopher, The changing automotive environment: high-temperature electronics. IEEE T. Electron. Pack. 27, 164–176 (2005). https://doi.org/10.1109/tepm.2004.843109.

C. Pei, C. Chen, K. Suganuma, and G. Fu, Thermal stability of silver paste sintering on coated copper and aluminum substrates. J. Electron. Mater. 47, 811–819 (2018). https://doi.org/10.1007/s11664-017-5857-2.

F. Yang, W. Zhu, Wu. Weizhen, H. Ji, C. Hang, and M. Li, Microstructural evolution and degradation mechanism of SiC-Cu chip attachment using sintered Nano-Ag paste during high-temperature ageing. J. Alloy. Compd. 846, 156442 (2020). https://doi.org/10.1016/j.jallcom.2020.156442.

J. Fan, G. Li, K. Rajavel, P. Zhu, and C.P. Wong, Synergistic size and shape effect of dendritic silver nanostructures for low-temperature sintering of paste as die attach materials. J. Mater. Sci. Mater. EL 32(1), 323–336 (2021). https://doi.org/10.1007/s10854-020-04783-9.

D.M. Rhee, H.Y. Hwang, J. Aw, S.L. Ho, and P.S. Ravinder, High power SiC inverter module packaging solutions for junction temperature over 220°C. IEEE T. Electron. Pack. (2014). https://doi.org/10.1109/eptc.2014.7028383.

C. Chen, C. Choe, D. Kim, Z. Zhang, X. Long, Z. Zhou, F. Wu, and K. Suganuma, Effect of oxygen on microstructural coarsening behaviors and mechanical properties of Ag sinter paste during high-temperature storage from macro to micro. J. Alloy. Compd. 834, 155173 (2020). https://doi.org/10.1016/j.jallcom.2020.155173.

R. Khazaka, M.L. Locatelli, S. Diaham, and P. Bidan, Effects of mechanical stresses, thickness and atmosphere on aging of polyimide thin films at high temperature. Polym. Degrad. Stabil. 98, 361–367 (2013). https://doi.org/10.1016/j.polymdegradstab.2012.09.005.

Q. Wang, S. Zhang, T. Lin, P. Zhang, P. He, and K.W. Paik, Highly mechanical and high-temperature properties of Cu-Cu joints using citrate-coated nanosized Ag paste in air. Prog. Nat. Sci. 31, 129–140 (2021). https://doi.org/10.1016/j.pnsc.2020.12.004.

C. Pei, C.T. Chen, K. Suganuma, and G.C. Fu, Thermal stability of silver paste sintering on coated copper and aluminum substrates. J. Electron. Mater. 47(1), 811–819 (2018). https://doi.org/10.1007/s11664-017-5857-2.

J.G. Bai, Z.Z. Zhang, J.N. Calata, and G.-Q. Lu, Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material. IEEE T. Comp. Pack. Man. 29(3), 589–593 (2006). https://doi.org/10.1109/tcapt.2005.853167.

S. Chen, C. Labarbera, and N.C. Lee, Silver sintering paste rendering low porosity joint for high power die attach application. Add. Conf. Dev. Pack. HiTEC HiTEN CICMT (2016). https://doi.org/10.4071/2016-hitec-134.

R.Z. Li, A. Hu, D. Bridges, T. Zhang, K.D. Oakes, R. Peng, U. Tumuluri, Z. Wu, and Z. Feng, Robust Ag nanoplate ink for flexible electronics packaging. Nanoscale 7(16), 7368–7377 (2015). https://doi.org/10.1039/c5nr00312a.

S. Katsuaki, Current status of joining ceramics and metals. Ceramist 9, 30–36 (2006).

T. Kunimune, M. Kuramoto, S. Ogawa, M. Nogi, and K. Suganuma, Low-temperature pressure-less silver direct bonding. IEEE T. Comp. Pack. Man. 3, 363–369 (2013). https://doi.org/10.1109/tcpmt.2012.2231901.

W. Wang, G. Zou, Q. Jia, H. Zhang, B. Feng, Z. Deng, and L. Liu, Mechanical properties and microstructure of low temperature sintered joints using organic-free silver nanostructured film for die attachment of SiC power electronics. Mater. Sci. Eng. A Struct. 793, 139894 (2020). https://doi.org/10.1016/j.msea.2020.139894.

Z. Liu, J. Cai, Q. Wang, Z. Wang, L. Liu, and G. Zou, Thermal-stable void-free interface morphology and bonding mechanism of low-temperature Cu-Cu bonding using Ag nanostructure as intermediate. J. Alloy. Compd. 767, 575–582 (2018). https://doi.org/10.1016/j.jallcom.2018.07.060.

J. Qiang, Z. Guisheng, Z. Hongqiang, W. Wengan, D. Zhongyang, R.H.L. Lei, P. Peng, and G. Wei, Research progress in sintering-bonding with nanoparticle materials as interlayer and its packaging application. J. Mech. Eng. 58, 2–16 (2022). https://doi.org/10.3901/JME.2022.02.002.

S.A. Paknejad, and S.H. Mannan, Review of silver nanoparticle based die attach materials for high power/temperature applications. Microelectron. Reliab. 70, 1–11 (2017). https://doi.org/10.1016/j.microrel.2017.01.010.

M.A. Asoro, D. Kovar, and P.J. Ferreira, Effect of surface carbon coating on sintering of silver nanoparticles: in situ TEM observations. Chem. Commun. 50(37), 4835–4838 (2014). https://doi.org/10.1039/c4cc01547a.

J. Yan, G. Zou, A.P. Wu, J. Ren, J. Yan, A. Hu, and Y. Zhou, Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scripta Mater. 66, 582–585 (2012). https://doi.org/10.1016/j.scriptamat.2012.01.007.

S. Zabihzadeh, S. Van Petegem, L.I. Duarte, R. Mokso, A. Cervellino, and H. Van Swygenhoven, Deformation behavior of sintered nanocrystalline silver layers. ACTA Mater. 97, 116–123 (2015). https://doi.org/10.1016/j.actamat.2015.06.040.

C. Chen, Z. Zhang, and K. Suganuma, Advanced SiC power module packaging technology direct on DBA substrate for high temperature applications: Ag sinter joining and encapsulation resin adhesion. IEEE T Electron. Pack. (2020). https://doi.org/10.1109/ECTC32862.2020.00223.

S. Nishimoto, Y. Nagatomo, T. Nagase, Development of direct bonded aluminum substrates with sintered Ag layer for SiC power modules. PCIM, (2015) 3924.

K. Lu, Sintering of nanoceramics. Int. Mater. Rev. (2008). https://doi.org/10.1179/174328008X254358.

H. Fang, C. Wang, S. Zhou, Q. Kang, and T. Suga, Rapid pressureless and low-temperature bonding of large-area power chips by sintering two-step activated Ag paste. J. Mater. Sci. Mater. EL 31(8), 6497–6505 (2020). https://doi.org/10.1007/s10854-020-03207-y.

Z.P. Bažant, Z.P. Bazant, and K.H.J. Buschow, Creep of concrete. Encycl. Mater. Sci. Technol. (2001). https://doi.org/10.1016/B0-08-043152-6/00325-9.

J.E. Blendell, and W. Rheinheimer, Solid-state sintering. Ref. Mod. Mater. Sci. Mater. Eng. (2020). https://doi.org/10.1016/B0-08-043152-6/01564-3.

C. Chen, S. Nagao, K. Suganuma, J. Jiu, and K. Tsuruta, Self-healing of cracks in Ag joining layer for die-attachment in power devices. Appl. Phys. Lett. 109, 93503 (2016). https://doi.org/10.1063/1.4962333.

P.G. Neudeck, Silicon carbide electronic devices. Encycl. Mater. Sci. Technol. (2001). https://doi.org/10.1016/B0-08-043152-6/01520-5.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (52205324) and the R&D Program of the Beijing Municipal Education Commission (KZ202210005005).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, L., Wang, Y., Jia, Q. et al. Low-Temperature-Sintered Nano-Ag Film for Power Electronics Packaging. J. Electron. Mater. 53, 228–237 (2024). https://doi.org/10.1007/s11664-023-10763-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-023-10763-6