Abstract

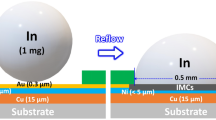

Although gold remains a preferred surface finish for components used in high-reliability electronics, rapid developments in this area have left a gap in the fundamental understanding of solder joint gold (Au) embrittlement. Furthermore, as electronic designs scale down in size, the effect of Au content is not well understood on increasingly smaller solder interconnections. As a result, previous findings may have limited applicability. The current study focused on addressing these gaps by investigating the interfacial microstructure that evolves in 63Sn-37Pb solder joints as a function of Au layer thickness. Those findings were correlated to the mechanical performance of the solder joints. Increasing the initial Au concentration decreased the mechanical strength of a joint, but only to a limited degree. Kirkendall voids were the primary contributor to low-strength joints, while brittle fracture within the intermetallic compounds (IMC) layers is less of a factor. The Au embrittlement mechanism appears to be self-limiting, but only once mechanical integrity is degraded. Sufficient void evolution prevents continued diffusion from the remaining Au.

Similar content being viewed by others

References

P. Vianco, Soldering Handbook, 3rd ed., (Miami: American Welding Society, 1999).

M. Wolverton, in IPC APEX EXPO Conference Proceedings, 2015.

P. Vianco, A Review of Interface Microstructures in Electronic Packaging Applications: Soldering Technology. J. Mater. 71, 1 (2018).

D. Crowe, A. Feinberg, Design for Reliability, 1st edn. (CRC Press, 2001)

M.H. Bester, in International Electronics Packaging and Production Conference Proceedings (1968), p. 211

F. Foster, in Papers on Soldering (1963) ASTM International.

W.B. Harding, H.G. Pressley, in 50th Annual Convention: American Electroplaters' Society Conference Proceedings (1963), p. 90

Hare, E., Gold Embrittlement of Solder Joints. 2010, SEM Lab, Inc.

C. Hillman, N. Blattau, J. Arnold, T. Johnston, and S. Gulbrandsen, Gold Embrittlement in Leadfree Solder. SMTA J. 26, 4 (2013).

B. Lee, J. Plante, (2006), NASA GSFC, Code 562.

H. Manko, Solders and Soldering, 2nd ed., (New York: McGraw-Hill, 1979).

M. Schwartz, Soldering: Understanding the Basics, 1st edn. (ASM International, Ohio, 2014)

H.A.H. Steen and G. Becker, The Effect of Impurity Elements on the Soldering Properties of Eutectic and Near Eutectic Tin-Lead Solders. Brazing Solder. (UK) 11, 4 (1986).

R. Strauss, SMT Soldering Handbook, 2nd ed., (Oxford: Newnes, 1998).

D.F. Susan, P.T. Vianco, R.P. Grant, P. Hlava, A.C. Kilgo, and G.L. Zender, Microscopy of Solder Joint Failures Due to Gold Intermetallic Embrittlement. Microsc. Microanal. 11, 1600 (2005).

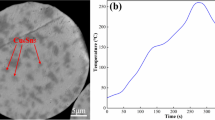

S.V. Prasad, P.G. Kotula, J.R. Michael, P.T. Vianco, Direct Visualization of Kirkendall Voids from In-situ TEM Heating Studies, Internal Report, (Sandia National Lab, Albuquerque, NM 2019)

P. Vianco, G. Bryant, P. Hlava, and G. Zender, Interface Reactions Between 50In-50Pb Solder and Electroplated Au Layers. Mater. Sci. Eng. A 409, 179 (2005).

K. Yamamoto, T. Kato, T. Kawamura, H. Nakano, M. Koizumi, H. Akahoshi, and R. Satoh, The Embrittlement Mechanism and Improvement of Impact Strength for Lead-Free Solder Joints in BGA Packaging Using Electrolytic Ni/Au Plating. Welding Interntl 23, 7 (2009).

J.A. Davis, M.J. Bozack, and J.L. Evans, Effect of (Au, Ni)Sn4 Evolution on Sn-37Pb/ENIG Solder Joint Reliability Under Isothermal and Temperature-Cycled Conditions. IEEE Trans. Compon. Packag. Manuf. Technol. 30, 1 (2007).

Z. Mei, P. Callery, D. Fisher, F. Hua, J. Glazer, in Pacific Rim/ASME International Intersociety Elect. and Photonic Pack. Conference Proceedings (1997), p. 1543

D. Morilla, A.L. Genua, D. Nunez, M. Dominguez, Degolding and Retinning Processes on Leadless SMD Packaged Devices. (Alter Technology 2019), https://wpo-altertechnology.com/degolding-retinning-processes-leadless-smd-packaged-devices/. Accessed 1 Jul 2020.

P. Vianco, An overview of surface finishes and their role in printed circuit board solderability and solder joint performance. Circuit World 25 (1998).

Acknowledgments

Sandia National Laboratories is a multimission laboratory managed and operated by National Technology and Engineering Solutions of Sandia, LLC., a wholly owned subsidiary of Honeywell International, Inc., for the U.S. Department of Energy's National Nuclear Security Administration under contract DE-NA-0003525. This article has been authored by an employee of National Technology & Engineering Solutions of Sandia, LLC under Contract No. DE-NA0003525 with the U.S. Department of Energy (DOE). The views expressed in this article do not necessarily represent the views of the U.S. Department of Energy or the United States Government. The United States Government retains and the publisher, by accepting the article for publication, acknowledges that the United States Government retains a non-exclusive, paid-up, irrevocable, world-wide license to publish or reproduce the published form of this article or allow others to do so, for United States Government purposes. The DOE will provide public access to these results of federally sponsored research in accordance with the DOE Public Access Plan https://www.energy.gov/downloads/doe-public-access-plan. Authors would like to extend thanks to the members of the Sandia Metallography Lab (Christina Profazi, Jeier Yang, and Alex Hickman) for always delivering high quality metallographic samples that enable the analyses discussed above as well as to Dr. Don Susan for providing a thorough review. Authors would also like to thank Somuri Prasad for providing initial guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wheeling, R., Vianco, P., Williams, S. et al. Impact of Gold Thickness on Interfacial Evolution and Subsequent Embrittlement of Tin–Lead Solder Joints. J. Electron. Mater. 51, 7337–7352 (2022). https://doi.org/10.1007/s11664-022-09891-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09891-2