Abstract

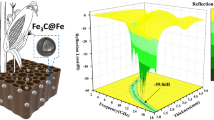

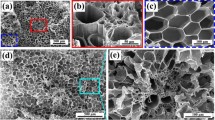

An activated carbon/epoxy composite was synthesized in which waste mango leaves biomass was used as the carbon source. To create a sufficient amount of porosity in the biomass, a simple process of carbonization followed by its activation was used. The morphology and porosity of the activated carbon material were studied by SEM, TEM, and BET analysis, which confirmed the presence of macro- and mesopores in the material. The activated carbon/epoxy composite with 3 mm thickness gave the highest reflection loss (RL) of − 39.57 dB at 6.48 GHz. At a thickness of just 2 mm the maximum effective absorption bandwidth (RL < − 10 dB) of 2.14 GHz was achieved. This excellent microwave absorption performance was attributed to the porous and bowl-type structure, which resulted in large surface area, high impedance matching, and subsequent attenuation of microwaves by conduction losses, as well as interfacial and dipolar polarization processes. This study provides a porous activated carbon/epoxy composite that is lightweight and economical, and has a high structural stability for microwave absorption applications.

Graphical Abstract

Similar content being viewed by others

References

L. Liu, S. Yang, H. Hu, T. Zhang, Y. Yuan, Y. Li, X. He, and A.C.S. Sustain, Chem. Eng. 7, 1228 (2019).

N. Li, G.W. Huang, Y.Q. Li, H.M. Xiao, Q.P. Feng, N. Hu, S.Y. Fu, and A.C.S. Appl, Mater. Interfaces 9, 2973 (2017).

X. Qiu, L. Wang, H. Zhu, Y. Guan, and Q. Zhang, Nanoscale 9, 7408 (2017).

F. Wen, F. Zhang, and Z. Liu, J. Phys. Chem. C 115, 14025 (2011).

B.P. Singh, V. Choudhary, P. Saini, S. Pande, V.N. Singh, and R.B. Mathur, J. Nanoparticle Res. 15, 1554 (2013).

L. Deng, and M. Han, Appl. Phys. Lett. 91, 023119 (2007).

P. Liu, Z. Yao, J. Zhou, Z. Yang, and L.B. Kong, J. Mater. Chem. C 4, 9738 (2016).

M. Fu, Q. Jiao, Y. Zhao, and H. Li, J. Mater. Chem. A 2, 735 (2014).

J. Feng, Y. Hou, Y. Wang, L. Li, and A.C.S. Appl, Mater. Interfaces 9, 14103 (2017).

R. Shu, W. Li, X. Zhou, D. Tian, G. Zhang, Y. Gan, J. Shi, and J. He, J. Alloys Compd. 743, 163 (2018).

C. Wang, X. Han, P. Xu, X. Zhang, Y. Du, S. Hu, J. Wang, and X. Wang, Appl. Phys. Lett. 98, 072906 (2011).

W. Ma, H. Chen, S. Hou, Z. Huang, Y. Huang, S. Xu, F. Fan, Y. Chen, and A.C.S. Appl, Mater. Interfaces 11, 25369 (2019).

P. Liu, Y. Zhang, J. Yan, Y. Huang, L. Xia, and Z. Guang, Chem. Eng. J. 368, 285 (2019).

Y. Zhang, Y. Huang, T. Zhang, H. Chang, P. Xiao, H. Chen, Z. Huang, and Y. Chen, Adv. Mater. 27, 2049 (2015).

Z. Wu, K. Tian, T. Huang, W. Hu, F. Xie, J. Wang, M. Su, L. Li, and A.C.S. Appl, Mater. Interfaces 10, 11108 (2018).

H. Guan, Q. Wang, X. Wu, J. Pang, Z. Jiang, G. Chen, C. Dong, L. Wang, and C. Gong, Compos. Part B. 207, 108562 (2021).

P. Negi, A.K. Chhantyal, A.K. Dixit, S. Kumar, and A. Kumar, Sustain. Mater. Technol. 27, e00244 (2021).

J. Fang, Y. Shang, Z. Chen, W. Wei, Y. Hu, X. Yue, and Z. Jiang, J. Mater. Chem. C 5, 4695 (2017).

L. Wang, P. Zhou, Y. Guo, J. Zhang, X. Qiu, Y. Guan, M. Yu, H. Zhu, and Q. Zhang, RSC Adv. 9, 9718 (2019).

Q. Liu, D. Zhang, and T. Fan, Appl. Phys. Lett. 93, 013110 (2008).

Y. Wei, H. Liu, S. Liu, M. Zhang, Y. Shi, J. Zhang, L. Zhang, and C. Gong, Compos. Commun. 9, 70 (2018).

J. Fang, T. Liu, Z. Chen, Y. Wang, W. Wei, X. Yue, and Z. Jiang, Nanoscale 8, 8899 (2016).

H. Zhao, Y. Cheng, H. Lv, G. Ji, and Y. Du, Carbon N.Y. 142, 245 (2019).

P. Negi, and A. Kumar, Nanoscale Adv. 3, 4196 (2021).

B.P. Singh, K. Saini, V. Choudhary, S. Teotia, S. Pande, P. Saini, and R.B. Mathur, J. Nanoparticle Res. 16, 2161 (2014).

R. Kumar, S.R. Dhakate, P. Saini, and R.B. Mathur, RSC Adv. 3, 4145 (2013).

V.C. Tung, M.J. Allen, Y. Yang, and R.B. Kaner, Nat. Nanotechnol. 4, 25 (2009).

H. Zhao, Y. Cheng, J. Ma, Y. Zhang, G. Ji, and Y. Du, Chem. Eng. J. 339, 432–441 (2018).

K.S.W. Sing, D.H. Everett, R.A.W. Haul, L. Moscou, R.A. Pierotti, J. Rouquerol, and T. Siemieniewska, Pure Appl. Chem. 57, 603 (1985).

M. Zhang, C. Han, W.Q. Cao, M.S. Cao, H.J. Yang, and J. Yuan, Nano-Micro Lett. 13, 27 (2021).

C. Zhou, S. Geng, X. Xu, T. Wang, L. Zhang, X. Tian, F. Yang, H. Yang, and Y. Li, Carbon N.Y. 108, 234 (2016).

B. Zhang, J. Wang, X. Su, H. Duan, H. Cai, J. Wang, S. Yang, and S. Huo, J. Mater. Sci. Mater. Electron. 28, 12122 (2017).

F. Qin, and C. Brosseau, J. Appl. Phys. 111, 061301 (2012).

B. Quan, W. Gu, J. Sheng, X. Lv, Y. Mao, L. Liu, X. Huang, Z. Tian, and G. Ji, Nano Res. 14, 1495 (2021).

W. Gu, X. Cui, J. Zheng, J. Yu, Y. Zhao, and G. Ji, J. Mater. Sci. Technol. 67, 265 (2021).

Y. Arooj, Y. Zhao, X. Han, T. Bao, and Y. Wang, Polym. Adv. Technol. 26, 620 (2015).

F. Ren, G. Zhu, Y. Wang, and X. Cui, J. Polym. Res. 21, 1–7 (2014).

S. E. Lee, O. Choi, and H. T. Hahn, J. Appl. Phys. 104 (2008).

F. Nanni, P. Travaglia, and M. Valentini, Compos. Sci. Technol. 69, 485 (2009).

Y. Wang, F. Luo, W. Zhou, and D. Zhu, Ceram. Int. 40, 10749 (2014).

H. Hosseini, and H. Mahdavi, Appl. Organomet. Chem. 32, 1 (2018).

S. Das, G. Chandra Nayak, S.K. Sahu, and R. Oraon, J. Magn. Magn. Mater. 384, 224 (2015).

C.C. Chen, W.F. Liang, Y.H. Nien, H.K. Liu, and R. Bin Yang, Mater. Res. Bull. 96, 81 (2017).

R.B. Yang, and W.F. Liang, J. Appl. Phys. 113, 15 (2013).

X. Su, J. Wang, X. Zhang, S. Huo, W. Chen, W. Dai, and B. Zhang, Ceram. Int. 46, 12353 (2020).

M.S. Cao, X.X. Wang, M. Zhang, J.C. Shu, W.Q. Cao, H.J. Yang, X.Y. Fang, and J. Yuan, Adv. Funct. Mater. 29, 1807398 (2019).

Z. Jiang, H. Si, X. Chen, H. Liu, L. Zhang, Y. Zhang, C. Gong, and J. Zhang, Compos. Commun. 22, 100503 (2020).

X. Wang, W. Cao, M. Cao, and J. Yuan, Adv. Mater. 32, 2002112 (2020).

M. Zhang, Z. Jiang, X. Lv, X. Zhang, Y. Zhang, J. Zhang, L. Zhang, and C. Gong, J. Phys. D. Appl. Phys. 53, 1–10 (2020).

Acknowledgments

Author Praveen Negi is thankful to the Director, National Institute of Technology Kurukshetra for providing Institute fellowship. The authors are also thankful to the Director, DMSRDE, DRDO Kanpur for VNA characterization.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Negi, P., Kumar, A. Biomass-Derived Activated Carbon/Epoxy Composite as Microwave Absorbing Material. J. Electron. Mater. 51, 2918–2925 (2022). https://doi.org/10.1007/s11664-022-09558-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09558-y