Abstract

Porous SnO2 with high sensitivity and fast response has attracted much attention. Herein, we prepared 3D porous SnO2 using carbon balls as a template and studied the effects of sintering time (1 h, 2 h, 3 h, 4 h) at a certain calcination temperature of 500℃ and Ho doping on the gas-sensing performance of 3D porous SnO2. The gas-sensing test results show that, compared with the samples obtained under other sintering time, the gas-sensing property of 3D porous SnO2 calcined for 2 h has the highest gas sensitivity of 31 in the 50-ppm formaldehyde environment. Among the samples doped with Ho, 3D porous SnO2 with a doping amount of 3.5% has the highest sensitivity of 65 at operating temperature of 230℃, which is twice as long as pure 3D porous SnO2 with a calcination time of 2 h. Moreover, the sample has good selectivity, low detection limit, and good linearity. These excellent gas-sensing characteristics are mainly due to the unique morphology of 3D porous SnO2, more oxygen vacancies, and the influence of Ho doping. Therefore, the gas-sensing performance of the metal oxide semiconductor material can be further improved by forming the porous nanocomposite material.

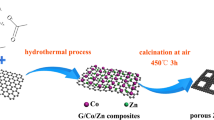

Graphical Abstract

(a) Response recovery time of SnO2 obtained under different calcination times;

(b) Response recovery time of SnO2 doped with different Ho content.

Similar content being viewed by others

References

D. Patil, P. Patil, V. Subramanian et al., Highly sensitive and fast responding CO sensor based on Co3O4 nanorods. Talanta 81, 37 (2010).

J.H. Bang, M.S. Choi, A. Mirzaei et al., Porous Si/SnO2 nanowires heterostructures for H2S gas sensing. Ceram. Int. 46, 604 (2020).

W. Zhang, Q. Li, C. Wang et al., High sensitivity and selectivity chlorine gas sensors based on 3D open porous SnO2 synthesized by solid-state method. Ceram. Int. 45, 20566 (2019).

C. Tian, H. Guo, H. Li et al., Constructing 3D porous SnO2 nanomaterials for enhanced formaldehyde sensing performances. J. Mater. Sci.: Mater. Electron. 31, 14174 (2020).

H.-J. Cho, S.-J. Choi, N.-H. Kim, and I.-D. Kim, Porosity controlled 3D SnO2 spheres via electrostatic spray: Selective acetone sensors. Sens. Actuators B-Chem. 304, 127350 (2020).

R. Niemela, and H. Vainio, Formaldehyde exposure in work and the general environment. Occurrence and possibilities for prevention. Scand. J Work Environ Health 7, 95 (1981).

Xia C. Discussion on indoor formaldehyde treatment. In: Sustainable Environment and Transportation, Pts 1-4. Edited by: Chu MJ, Xu HH, Jia Z et al. 2012. pp. 280-283.

P. Gao, X.-Y. Sun, B. Liu et al., Cu MOF-based catalytic sensing for formaldehyde. J. Mater. Chem. C 6, 8105 (2018).

F. Ren, L. Gao, Y. Yuan et al., Enhanced BTEX gas-sensing performance of CuO/SnO2 composite. Sens. Actuators B-Chem. 223, 914 (2016).

T.Y. Ho, J.-W. Huang, B.-C. Peng et al., Liquid crystal-based sensor system for detecting formaldehyde in aqueous solutions. Microchem. J. 158, 105235 (2020).

K. Khojier, Preparation and investigation of Al-doped ZnO thin films as a formaldehyde sensor with extremely low detection limit and considering the effect of RH. Mater. Sci. Semiconduct. Process. 121, 105283 (2021).

L. Xu, M. Ge, F. Zhang et al., Nanostructured of SnO2/NiO composite as a highly selective formaldehyde gas sensor. J. Mater. Res. 35, 3079 (2020).

L. Liu, S. Li, X. Guo et al., Excellent performance of gas sensor based on In2O3-Fe2O3 nanotubes. J. Semiconduct. 37, 013005 (2016).

X. Xu, J. Sun, H. Zhang et al., Effects of Al doping on SnO2 nanofibers in hydrogen sensor. Sens. Actuators B-Chem. 160, 858 (2011).

S.-W. Choi, A. Katoch, G.-J. Sun, and S.S. Kim, Synthesis and gas sensing performance of ZnO-SnO2 nanofiber-nanowire stem-branch heterostructure. Sens. Actuators B-Chem. 181, 787 (2013).

L. Xu, R. Xing, J. Song et al., ZnO-SnO2 nanotubes surface engineered by Ag nanoparticles: synthesis, characterization, and highly enhanced HCHO gas sensing properties. J. Mater. Chem. C 1, 2174 (2013).

J. Zhang, X. Liu, L. Wang et al., Synthesis and gas sensing properties of alpha-Fe2O3@ZnO core-shell nanospindles. Nanotechnology 22, 18550 (2011).

P.N. Anantharamaiah, and S. Giri, Enhancement of SO2 gas sensing performance of Co3O4 spinel by Cu substitution. Sens. Lett. 18, 83 (2020).

J. Ma, H. Fan, W. Zhang et al., High sensitivity and ultra-low detection limit of chlorine gas sensor based on In2O3 nanosheets by a simple template method. Sens. Actuators B Chem. 305, 127456 (2020).

X. Zeng, Z. Wang, Y. Li et al., Highly sensitive and selective formaldehyde gas sensor based on CdO-In2O3 beaded porous nanotubes at low temperature. J. Mater. Sci. Mater. Electron. 29, 17533–17541 (2018).

J. Kim, J.-H. Yun, and C.-S. Han, Nanomaterial-embedded gas sensor fabrication. Curr. Appl. Phys. 9, e38–e41 (2009).

Y. Xu, L. Zheng, C. Yang et al., Highly sensitive and selective electronic sensor based on Co catalyzed SnO2 nanospheres for acetone detection. Sens. Actuators B-Chem. 304, 127237 (2020).

J. Fan, L. Zhao, J. Yu, and G. Liu, The effect of calcination temperature on the microstructure and photocatalytic activity of TiO2-based composite nanotubes prepared by an in situ template dissolution method. Nanoscale 4, 6597 (2012).

M. Zhu, T. Yang, C. Zhai et al., Fast triethylamine gas sensing response properties of Ho-doped SnO2 nanoparticles. J. Alloys Compd. 817, 152724 (2020).

K. Suematsu, H. Uchino, T. Mizukami et al., Oxygen adsorption on ZrO2-loaded SnO2 gas sensors in humid atmosphere. J. Mater. Sci. 54, 3135 (2019).

L.-L. Li, W.-M. Zhang, Q. Yuan et al., Room temperature ionic liquids assisted green synthesis of nanocrystalline porous SnO2 and their gas sensor behaviors. Cryst. Growth Des. 8, 4165 (2008).

B. Zheng, S. Wu, X. Yang et al., Room temperature CO oxidation over Pt/MgFe2O4: a stable inverse spinel oxide support for preparing highly efficient Pt catalyst. ACS Appl. Mater. Interfaces 8, 26683 (2016).

T. Zhou, G. Zhang, H. Yang et al., Fabrication of Ag3PO4/GO/NiFe2O4 composites with highly efficient and stable visible-light-driven photocatalytic degradation of rhodamine B. RSC Adv. 8, 28179 (2018).

Z. Yan, J. Gao, Y. Li et al., Hydrothermal synthesis and structure evolution of metal-doped magnesium ferrite from saprolite laterite. RSC Adv. 5, 92778 (2015).

R. Zhang, Z. Xu, T. Zhou et al., Improvement of gas sensing performance for tin dioxide sensor through construction of nanostructures. J. Colloid Interface Sci. 557, 673 (2019).

G.H. Jain, L.A. Patil, and V.B. Gaikwad, Studies on gas sensing performance of (Ba0.8Sr0.2)(Sn0.8Ti0.2)O-3. Sensors Actuators B-Chem. 122, 605 (2007).

N.-H. Kim, S.-J. Choi, S.-J. Kim et al., Highly sensitive and selective acetone sensing performance of WO3 nanofibers functionalized by Rh2O3 nanoparticles. Sens. Actuators B-Chem. 224, 185 (2016).

V. Kruefu, A. Wisitsoraat, A. Tuantranont, and S. Phanichphant, Ultra-sensitive H2S sensors based on hydrothermal/impregnation-made Ru-functionalized WO3 nanorods. Sens. Actuators B-Chem. 215, 630 (2015).

P. Rai, S.M. Majhi, Y.-T. Yu, and J.-H. Lee, Noble metal@metal oxide semiconductor core@shell nano-architectures as a new platform for gas sensor applications. RSC Adv. 5, 76229 (2015).

C. Wang, L. Yin, L. Zhang et al., Metal oxide gas sensors: sensitivity and influencing factors. Sensors 10, 2088–2106 (2010).

L. Song, B. Zhao, X. Ju et al., Comparative study of methanol gas sensing performance for SnO2 nanostructures by changing their morphology. Mater. Sci. Semiconduct. Process. 111, 1049 (2020).

L. Wu, L. Zhang, Z. Xun et al., Effect of growth temperature and time on morphology and gas sensitivity of Cu2O/Cu microstructures. J Nanomater 2016, 1 (2016).

J. Hu, H. Wang, M. Chen et al., Constructing hierarchical SnO2 nanoflowers for enhanced formaldehyde sensing performances. Mater. Lett. 263, 126843 (2020).

H. Duan, Y. Wang, S. Li et al., Controllable synthesis of Ho-doped In2O3 porous nanotubes by electrospinning and their application as an ethanol gas sensor. J. Mater. Sci. 53, 3267 (2018).

Y. Zhang, S. Guo, and Z. Zheng, Nanocrystalline Ho3+-doped WO3: a promising material for acetone detection. J. Exp. Nanosci. 8, 184 (2013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tian, C., Tian, Xa., Li, Y. et al. Improve the Formaldehyde Gas-Sensing Performance of 3D Porous SnO2 by Controlling the Calcination Time and the Amount of Holmium Doped. J. Electron. Mater. 51, 214–222 (2022). https://doi.org/10.1007/s11664-021-09279-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09279-8