Abstract

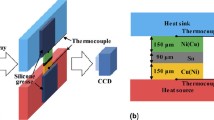

The protective effect of a Ni layer on Cu-Sn solder joints was investigated from the perspective of interface diffusion. The results indicate that temperature is the primary external factor affecting interfacial diffusion, and the effect of external load also has an influence. Atom diffusion is promoted by the increasing temperature and applied compressive load perpendicular to the interface. In contrast, the tensile load perpendicular to the interface inhibited the diffusion behavior. Ni atoms at both the Ni/Cu and Ni/Sn interfaces act as the main diffusion factor and play a vital role in the growth and evolution of the diffusion layer. Because of the high stability of the Ni lattice and the large radii of Cu and Sn atoms, it is difficult for Cu and Sn atoms to migrate to the Ni atoms, which effectively delays the contact and reaction between Cu and Sn. To reveal the micro-mechanism of the diffusion, the diffusion coefficient and activation energy were studied. Ni atoms need more energy than Cu and Sn atoms to drive the diffusion, which delays the consumption of Ni and helps to maintain the Ni layer. The single vacancy formation energy of the Ni lattice is the largest, which means that it is difficult for Cu and Sn atoms to migrate into the lattice. By comparing the atomic diffusion rate, the final formation of Cu-Sn intermetallic compounds in the Ni layer on the side of tin-based solder was predicted at a macroscopic time scale. Using density functional calculation, the slight lattice distortion of the interfaces was measured. The analysis of charge transfer and electronic properties show that a strong electron transfer and energy level overlap occurs between the Ni and Cu atoms, implying that the Ni/Cu interface has a more considerable electronic thermal conductivity and should be more sensitive to the increasing temperature.

Similar content being viewed by others

References

N. Jiang, L. Zhang, Z.Q. Liu, L. Sun, W.M. Long, P. He, M.Y. Xiong, and M. Zhao, Sci. Technol. Adv. Mater. 20, 876 (2019).

D.J. Lee and H.S. Lee, Microelectron. Reliab. 46, 1119 (2006).

H. Lee, C. Kim, C. Heo, C. Kim, J.H. Lee, and Y. Kim, Microelectron. Reliab. 87, 75 (2018).

Y.S. Kim, S.H. Kim, J.W. Shin, K.W. Paik, and I.E.E.E.T. Comp, Pack. Man. 5, 1350 (2015).

C. Chen, H.M. Tong, and K.N. Tu, Annu. Rev. Mater. Res. 40, 531 (2010).

P. Lall, S. Shantaram, J. Suhling, and D. Locker, J. Electron. Packag. 137, 011010 (2015).

D. Kim, J.Y. Chang, J. Park, and J.J. Pak, J. Mater. Sci.: Mater. Electron. 22, 703 (2011).

A.D. Smigelskas and E.O. Kirdendall, Trans. AIME 171, 130 (1947).

F. Seitz, Acta Metall. 1, 355 (1953).

A.E. Pazy and D.C. Dunand, Intermetallic 117, 106634 (2020).

C. Yu, J.S. Chen, Z.W. Cheng, Y.Q. Huang, J.M. Chen, J.J. Xu, and H. Xu, J. Alloys Compd. 66, 80 (2015).

Y. Zhao, K. Wang, S. Yuan, Y.H. Ma, G.J. Li, and Q. Wang, J. Mater. Sci. Technol. 46, 127 (2020).

K. Zeng, R. Stierman, T.C. Chiu, and D. Edwards, J. Appl. Phys. 97, 024508 (2005).

L. Xu, J. Pang, and F. Che, J. Electron. Mater. 37, 880 (2008).

P. Sun, C. Andersson, X.C. Wei, Z.N. Cheng, D. Shangguan, and J. Liu, Mater. Sci. Eng., B 135, 134 (2006).

J.S. Chen, J. Yang, Y.Z. Zhang, Z.S. Yu, and P.L. Zhang, Weld. World 63, 751 (2019).

T. Laurila, V. Vuorinen, and J.K. Kivilahti, Mater. Sci. Eng., R 49, 1 (2005).

C. Yu, Y. Yang, K.Y. Wang, J.J. Xu, J.M. Chen, and H. Lu, J. Mater. Sci.: Mater. Electron. 23, 124 (2012).

C.E. Ho, S.C. Yang, and C.R. Kao, J. Mater. Sci.: Mater. Electron. 18, 155 (2007).

Y.W. Wang, Y.W. Lin, and C.R. Kao, Reliability 49, 248 (2009).

S.S. Chee and J.H. Lee, Electron. Mater. Lett. 10, 637 (2014).

J.W. Yang, J. Zhang, and J. Qiao, Materials 12, 2306 (2019).

Y.Q. Zhang and S.Y. Jiang, Materials 11, 1967 (2018).

M. Baksi, D. Toffoli, O. Gulseren, and H. Ustunel, J. Phys. Chem. C 123, 28411 (2019).

R. Freitas, M. Asta, and M. de Koning, Comput. Mater. Sci. 112, 333 (2016).

A.I. Khan, R. Paul, and S. Subrina, RSC Adv. 7, 50485 (2017).

M. Motalab, R. Paul, S. Saha, S. Mojumder, T. Ahmed, and J.C. Suhling, J. Mol. Model. 25, 59 (2019).

M. Wouters, J. Tempere, and J.T. Devreese, Phys. Rev. A 66, 043414 (2002).

J.A. Snyman, Comput. Math Appl. 40, 1085 (2000).

C. Li, D.X. Li, X.M. Tao, H.M. Chen, and Y.F. Ouyang, Modell. Simul. Mater. Sci. Eng. 22, 065013 (2014).

N. Kaur, C. Deng, and O.A. Ojo, Comput. Mater. Sci. 179, 109685 (2019).

M. Wang, H.S. Liu, R.C. Wang, and J. Peng, Mater. Sci. Eng. A 773, 138738 (2020).

B. Onat and S. Durukanoglu, J. Phys.: Condens. Matter 26, 035404 (2014).

L.H. Li, W.L. Wang, and B. Wei, Comput. Mater. Sci. 99, 274 (2015).

A.V. Pham, T.H. Fang, A.S. Tran, and T.H. Chen, Superlattice. Microstruct. 139, 106402 (2020).

Y. Wang, N.S. Jiang, K.M. Miu, and Y. Wu, Comput. Mater. Sci. 171, 109272 (2020).

Y. Yang, Y.A. Lin, X.Y. Yan, C. Fei, Q. Shen, L.M. Zhang, N. Yan, and A.C.S. Appl, Energy Mater. 2, 8894 (2019).

J.R. Vella, M. Chen, F.H. Stillinger, E.A. Carter, P.G. Debenedetti, and A.Z. Panagiotopoulos, Phys. Rev. B 95, 064202 (2017).

M. Wang, H.S. Liu, R.C. Wang, and J. Peng, Mater. Sci. Eng. A 773, 138738 (2020).

W.W. Zhang, Y. Ma, W. Zhou, and P. Wu, J. Electron. Mater. 48, 4533 (2019).

X.Y. Bi, X.W. Hu, X.X. Jiang, and Q.L. Li, Vacuum 164, 7 (2019).

Z. Mao, J.S. Li, S.J. Dong, X. Lin, X.D. Jian, and P. Wu, Phys. E 120C, 113983 (2020).

K. Bruke, J.P. Perdew, and M. Ernzerhof, J. Chem. Phys. 109, 3760 (1998).

G. Kresse and J. Hafner, Phys. Rev. B 49, 14251 (1994).

H.J. Monkhorst and J.D. Pack, Phys. Rev. B 13, 5188 (1976).

J.C. Slater, J. Chem. Phys. 41, 3199 (1964).

J.C. Zhang, J. Yang, L.H. Liang, Y.J. Xu, and J. Guo, Mol. Phys. 116, 99 (2018).

F. Gao and J.M. Qu, Mater. Lett. 73, 92 (2012).

C.A. Mackliet, Phys. Rev. 109, 1964 (1958).

O. Taguchi, Y. Lijima, and K.I. Hirano, J. Jpn. Inst. Met. 48, 20 (1984).

D.C. Yeh and H.B. Huntington, Phys. Rev. Lett. 53, 1469 (1984).

R. Labie, W. Ruythooren, and J. van Humbeeck, Intermetallics 15, 396 (2007).

K.P.L. Pun, M.N. Islam, J. Rotanson, C.W. Cheung, and A.H.S. Chan, J. Electron. Mater. 47, 5191 (2018).

J. Bai, N. Xu, J.M. Raulot, Y.D. Zhang, C. Esling, X. Zhao, and L. Zuo, J. Appl. Phys. 113, 174901 (2013).

C. Woodward, S. Kajihara, and L.H. Yang, Phys. Rev. B 57, 13459 (1998).

Y.J. Li, Q.M. Hu, D.S. Xu, and R. Yang, Intermetallics 19, 793 (2011).

M. Mazalová, M. Všianská, J. Pavlů, and M. Šob, Nanomaterials 10, 691 (2020).

J.M. Zhang, X.L. Song, X.J. Zhang, and K.W. Xu, J. Phys. Chem. Solids 67, 714 (2006).

A. Lavasani, D. Bulmash, and S. das Sarma, Phys. Rev. B 99, 085104 (2019).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mao, Z., Zhang, W., Li, J. et al. The Obstruction Effect of Ni Layer on the Interdiffusion of Cu Substrate and Sn Solder: A Theoretical Investigation. J. Electron. Mater. 49, 6559–6571 (2020). https://doi.org/10.1007/s11664-020-08421-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08421-2