Abstract

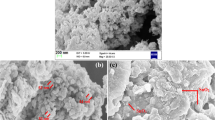

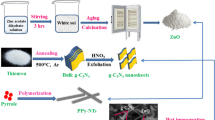

Nanocomposites based on silica, polypyrrole, and sodium dodecyl sulfate dopant (SiO2-PPy-DoS) were synthesized by an in situ polymerization method. The characterizations of the synthesized materials were analyzed using Fourier-transform infrared spectroscopy, energy dispersive x-ray analysis, scanning electron microscopy, thermal gravimetric analysis, and x-ray photoelectron spectroscopy. The results showed that the SiO2-PPy-DoS composite had spherical shape with size of around 250–500 nm. The electrical conductivity of the SiO2-PPy-DoS nanocomposite was measured to be around 0.287 S/cm, which was larger than that of SiO2-PPy (0.101 S/cm). An enhanced anti-corrosion protection of carbon steel substrate (CT3) using an epoxy coating containing SiO2-PPy-DoS was achieved with an impedance modulus value of 108 Ω cm−2 at 10 mHz after 840 h soaked in NaCl solution of 3%, indicating that DoS can be used as an additive to improve anti-corrosion capacity for carbon steel.

Similar content being viewed by others

References

C.M. Hansson, Metall. Mater. Trans. A 42A, 2952 (2011).

A. Popoola, O.E. Olorunniwo, and O.O. Ige, Developments in Corrosion Protection, ed. M. Aliofkhazraei (IntechOpen: Rijeka, 2014), p. 241.

S.S. Pathak, S.K. Mendon, M.D. Blanton, and J.W. Rawlins, Metals 2, 353 (2012).

C. Edeleanu, Platin. Met. Rev. 4, 86 (1960).

G. Williams, S. Geary, and H.N. McMurray, Corros. Sci. 57, 139 (2012).

R. Vera, R. Schrebler, P. Greza, and H. Romero, Prog. Org. Coat. 77, 853 (2014).

Y.W. Song, D.Y. Shan, and E.H. Han, Electrochim. Acta 53, 2135 (2008).

R.R. Hussain, J. Civil Environ. Eng. (2014). https://doi.org/10.4172/2165-784X.1000e116.

S.D.A.S. Ramôa, G.M.O. Barra, C. Merlini, W.H. Schreiner, S. Livi, and B.G. Soares, Appl. Clay Sci. 104, 160 (2015).

E. Hur, G.O. Bereket, and Y.U. Sahin, Mater. Chem. Phys. 100, 19 (2006).

J.G. Hyun, S.D. Cho, and K.W. Paik, J. Electron. Mater. 34, 1264 (2006).

V.T.H. Vu, T.T.M. Dinh, N.T. Pham, T.T. Nguyen, P.T. Nguyen, and H.T.X. To, Int. J. Corros. (2018). https://doi.org/10.1155/2018/6395803/.

V.T.H. Vu, N.T. Pham, T.T. Nguyen, P.T. Nguyen, H.T.X. To, and T.T.M. Dinh, Vietnam J. Chem. 55, 781 (2017).

V.T.H. Vu, H.T.X. To, N.T. Pham, P.T. Nguyen, T.T. Nguyen, D. Didier, and T.T.M. Dinh, J. Nanosci. Nanotech. (2018). https://doi.org/10.1166/jnn.2018.15198.

N. Romyen, S. Thongyai, P. Praserthdam, and S. Wacharawichanant, J. Electron. Mater. 46, 6709 (2017).

S. Konwer, R. Boruah, and S.K. Dolui, J. Electron. Mater. 40, 2448 (2011).

J. Wang, Y. Xu, X. Sun, S. Mao, and F. Xiao, J. Electrochem. Soc. 154, C445 (2007).

K. Yoshino, K. Kaneto, and S. Takeda, Synth. Met. 18, 741 (1987).

M. Rohwerder, Int. J. Mat. Res. 100, 1331 (2009).

N. Su, H.B. Li, S.J. Yuan, S.P. Yi, and E.Q. Yin, Expr. Polym. Lett. 6, 697 (2012).

K. Qi, Y. Qiu, Z. Chen, and X. Guo, Corros. Sci. 60, 50 (2012).

S.H. Yang, C.K. Yang, J.H. Yan, and C.M. Lin, J. Electron. Mater. 43, 3593 (2014).

Z. Xiang, Y. Wang, P. Ju, and D. Zhang, J. Electron. Mater. 46, 758 (2016).

M. Ramezani and S.M.H. Mashkani, J. Electron. Mater. 46, 1371 (2016).

T.K.O. Vuong, D.L. Tran, T.T. Vu, T.L. Le, H.N. Pham, T.T. Le, H.M. Do, and X.P. Nguyen, J. Electron. Mater. 45, 4010 (2016).

T. Ohtsuka, Int. J. Corr. (2012). https://doi.org/10.1155/2012/915090.

C.-H. Sha and C.C. Lee, J. Electron. Packag. 133, 021005 (2011).

ASTM-D4541, Standard test method for pull-off strength of coatings using portable adhesion testers (2010)

ASTM-D2794, Standard test method for resistance of organic coatings to the effects of rapid deformation (Impact) (2010)

F. Yang, Y. Chu, S. Ma, Y. Zhang, and J. Liu, J. Colloid Interface Sci. 301, 470 (2006).

Y.D. Kim and G. Hong, Korean J. Chem. Eng. 29, 964 (2012).

X. Liu, H. Wu, F. Ren, G. Qiu, and M. Tang, Mater. Chem. Phys. 109, 5 (2008).

I.Y. Jeon, H.J. Choi, L.S. Tan, and J.B. Baek, J. Polym. Sci. 49, 2529 (2011).

W. Su and J.O. Iroh, Electrochim. Acta 44, 2173 (1999).

C. Yang, X. Wang, Y. Wang, and P. Liu, Powder Technol. 217, 134 (2012).

N. Su, Nanoscale Res. Lett. 10, 301 (2015).

S.D.A.S. Ramôa, G.M.O. Barra, C. Merlini, W.H. Schreiner, S. Livi, and B.G. Soares, Appli. Clay Sci. 104, 160 (2015).

S. Konwer, R. Boruah, and S.K. Dolui, J. Electron. Mater. 40, 2248 (2011).

V. Schmidt, C. Giacomelli, and V. Soldi, Polym. Degrad. Stab. 87, 25 (2005).

D. Kowalski, M. Ueda, and T. Ohtsuka, Corr. Sci. 49, 3442 (2007).

A. Reung-u-rai, A. Prom-jun, W. Prissanaroon-ouajai, S. Ouajai, and J. Metals, Mater. Miner. 18, 27 (2008).

T. Liu, N. Liu, S. Zhai, S. Gao, Z. Xiao, Q. An, and D. Yang, J. Alloys Compd. 779, 831 (2019).

H. Veisi, B. Maleki, F.H. Eshbala, H. Veisi, R. Masti, S.S. Ashrafi, and M. Baghayeri, RSC Adv. 4, 30638 (2014).

T.X.H. To, T.A. Nguyen, A.T. Trinh, V.T. Bui, H. Thai, T.M.T. Dinh, and S. Daopiset, J. Coat. Technol. Res. 13, 805 (2016).

S. Abhijit and P.A. Mahanwar, Pigm. Resin Technol. 42, 317 (2013).

Acknowledgments

This research was funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant Number “104.06-2014.12”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen Thi, T., Dinh Thi Mai, T., Pham Thi, N. et al. Enhanced Anti-Corrosion Protection of Carbon Steel with Silica-Polypyrrole-Dodecyl Sulfate Incorporated into Epoxy Coating. J. Electron. Mater. 48, 3931–3938 (2019). https://doi.org/10.1007/s11664-019-07146-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07146-1