Abstract

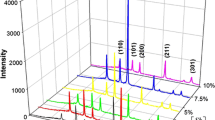

An electrochemical route has been employed to prepare undoped and Se-doped SnS thin films. Six samples including undoped and Se-doped SnS thin films were deposited on the fluorine-doped tin oxide glass substrate. An aqueous solution containing 2 mM SnCl2 and 16 mM Na2S2O3 was used in the electrolyte. Different Se-doped SnS samples were prepared by adding the various amounts of 4 mM SeO2 solution into the electrolyte. The applied potential (E), time of deposition process (t), pH, and bath temperature (T) were kept at − 1 V, 30 min, 2.1, and 60°C, respectively. After the completion of the deposition process, x-ray diffraction (XRD) and transmission electron microscopy (TEM) were utilized to characterize the deposited thin films. XRD patterns clearly showed that the synthesized undoped and Se-doped SnS thin films were crystallized in the orthorhombic structure. Using Scherrer’s method, the crystallite size of deposited thin films is calculated. In addition, the crystallite size and lattice strain have been estimated using the modified form of the Williamson–Hall (W–H) method containing a uniform deformation model, a uniform deformation stress model, a uniform deformation energy density model, and by the size–strain plot method (SSP). The shape of SnS crystals was spherical in TEM images. The results showed that there was a good agreement in the particle size obtained from the W–H method and the SSP method with TEM images.

Similar content being viewed by others

References

T.W. Cornelius and O. Thomas, Prog. Mater Sci. 94, 384 (2018).

S.K. Tippabhotla, I. Radchenko, K.N. Rengarajan, G. Illya, V. Handara, M. Kunz, N. Tamura, and A.S. Budiman, Procedia Eng. 139, 123 (2016).

A.S. Budiman, H.A.S. Shin, B.J. Kim, S.H. Hwang, H.Y. Son, M.S. Suh, Q.H. Chung, K.Y. Byun, N. Tamura, M. Kunz, and Y.C. Joo, Microelectron. Reliab. 52, 530 (2012).

D. Ferri, M.A. Newton, M. Di Michiel, S. Yoon, G.L. Chiarello, V. Marchionni, S.K. Matam, M.H. Aguirre, A. Weidenkaff, and F. Wen, Phys. Chem. Chem. Phys. 15, 8629 (2013).

H. Kafashan, Ceram. Int. 45, 334 (2019).

S. Polivtseva, A. Katerski, E. Kärber, I. Oja Acik, A. Mere, V. Mikli, and M. Krunks, Thin Solid Films 633, 179 (2017).

J.-Y. Kang, S.-M. Kwon, S.H. Yang, J.-H. Cha, J.A. Bae, and C.-W. Jeon, J. Alloys Compd. 711, 294 (2017).

H. Kafashan, F. Jamali-Sheini, R. Ebrahimi-Kahrizsangi, and R. Yousefi, Int. J. Miner. Metall. Mater. 23, 348 (2016).

H. Kafashan, F. Jamali-Sheini, M. Azizieh, Z. Balak, M. Cheraghizade, and H. Nasiri Vatan, J. Alloys Compd. 694, 1338 (2017).

H. Kafashan, F. Jamali-Sheini, R. Ebrahimi-Kahrizsangi, and R. Yousefi, J. Alloys Compd. 681, 595 (2016).

H. Kafashan, R. Ebrahimi-Kahrizsangi, F. Jamali-Sheini, and R. Yousefi, Phys. Status Solidi. A 213, 1302 (2016).

S. Banu, S.J. Ahn, Y.J. Eo, J. Gwak, and A. Cho, Sol. Energy 145, 33 (2017).

J. Kois, S. Bereznev, J. Maricheva, and N. Revathi, Mater. Sci. Semicond. Process. 58, 76 (2017).

B.H. Baby, V.M. Vaisakh, and D. Bharathi Mohan, Mater. Today Proc. 3, 2077 (2016).

P. Nwofe, K.R. Reddy, J. Tan, I. Forbes, and R. Miles, Phys. Procedia 25, 150 (2012).

A. Basak, A. Mondal, and U.P. Singh, Mater. Sci. Semicond. Process. 56, 381 (2016).

Y. Kawano, J. Chantana, and T. Minemoto, Curr. Appl. Phys. 15, 897 (2015).

S. Gedi, V.R.M. Reddy, J.-Y. Kang, and C.-W. Jeon, Appl. Surf. Sci. 402, 463 (2017).

F. Alam and V. Dutta, Appl. Surf. Sci. 358, 491 (2015).

G.G. Ninan, C.S. Kartha, and K.P. Vijayakumar, J. Anal. Appl. Pyrol. 120, 121 (2016).

M. Patel, I. Mukhopadhyay, and A. Ray, J. Alloys Compd. 619, 458 (2015).

T. Řičica, L. StŘižík, L. Dostál, M. Bouška, M. Vlček, L. Beneš, T. Wágner, and R. Jambor, Appl. Organomet. Chem. 29, 176 (2015).

K. Hosein, Mater. Res. Express 5, 046417 (2018).

H. Kafashan, Mater. Sci. Semicond. Process. 88, 148 (2018).

H. Kafashan, M. Azizieh, and Z. Balak, Appl. Surf. Sci. 410, 186 (2017).

H. Kafashan, M. Azizieh, and H. Nasiri Vatan, J. Alloys Compd. 686, 962 (2016).

H. Kafashan, and Z. Balak, Spectrochim. Acta, Part A 184, 151 (2017).

C. Gao, H. Shen, and L. Sun, Appl. Surf. Sci. 257, 6750 (2011).

H.Y. He, J. Fei, and J. Lu, Mater. Sci. Semicond. Process. 24, 90 (2014).

C. Gao and H. Shen, Thin Solid Films 520, 3523 (2012).

S. Gedi, V.R. Minnam Reddy, C. Park, J. Chan-Wook, and K.T. Ramakrishna Reddy, Opt. Mater. 42, 468 (2015).

A. Stadler, H.J. Schimper, U. Brendel, D. Topa, A. Basch, and H. Dittrich, Thin Solid Films 519, 7951 (2011).

L.L. Cheng, M.H. Liu, M.X. Wang, S.C. Wang, G.D. Wang, Q.Y. Zhou, and Z.Q. Chen, J. Alloys Compd. 545, 122 (2012).

W. Cai, J. Hu, Y. Zhao, H. Yang, J. Wang, and W. Xiang, Adv. Powder Technol. 23, 850 (2012).

F. Jiang, H. Shen, C. Gao, B. Liu, L. Lin, and Z. Shen, Appl. Surf. Sci. 257, 4901 (2011).

F. Zakerian, and H. Kafashan, Superlattices Microstruct. 124, 92 (2018).

A. Azmand, and H. Kafashan, Ceram. Int. 44, 17124 (2018).

T. Seymour, P. Frankel, L. Balogh, T. Ungár, S.P. Thompson, D. Jädernäs, J. Romero, L. Hallstadius, M.R. Daymond, G. Ribárik, and M. Preuss, Acta Mater. 126, 102 (2017).

T. Ungar, J. Gubicza, G. Ribarik, and A. Borbely, J. Appl. Crystallogr. 34, 298 (2001).

Z. Fan, B. Jóni, L. Xie, G. Ribárik, and T. Ungár, J. Nucl. Mater. 502, 301 (2018).

X. Chen, C. Dejoie, T. Jiang, C.-S. Ku, and N. Tamura, MRS Bull. 41, 445 (2016).

A.S. Budiman, G. Lee, M.J. Burek, D. Jang, S.M.J. Han, N. Tamura, M. Kunz, J.R. Greer, and T.Y. Tsui, Mater. Sci. Eng., A 538, 89 (2012).

I. Radchenko, S.K. Tippabhotla, N. Tamura, and A.S. Budiman, J. Electron. Mater. 45, 6222 (2016).

A. Davydok, T.W. Cornelius, C. Mocuta, E.C. Lima, E.B. Araujo, and O. Thomas, Thin Solid Films 603, 29 (2016).

X.M. Zeng, Z. Du, N. Tamura, Q. Liu, C.A. Schuh, and C.L. Gan, Acta Mater. 134, 257 (2017).

J. Kou, K. Chen, and N. Tamura, Scripta Mater. 143, 49 (2018).

N. Vaxelaire, S. Labat, T.W. Cornelius, C. Kirchlechner, J. Keckes, T. Schulli, and O. Thomas, Acta Mater. 78, 46 (2014).

R. Sivakami, S. Dhanuskodi, and R. Karvembu, Spectrochim. Acta, Part A 152, 43 (2016).

G.H. Khorrami, A. Khorsand Zak, A. Kompany, and R. Yousefi, Ceram. Int. 38, 5683 (2012).

A.S. Budiman, P.R. Besser, C.S. Hau-Riege, A. Marathe, Y.C. Joo, N. Tamura, J.R. Patel, and W.D. Nix, J. Electron. Mater. 38, 379 (2009).

A. Budiman, W. Nix, N. Tamura, B. Valek, K. Gadre, J. Maiz, R. Spolenak, and J. Patel, Appl. Phys. Lett. 88, 233515 (2006).

T.M.K. Thandavan, S.M.A. Gani, C. San Wong, and R.M. Nor, J. Nondestr. Eval. 34, 14 (2015).

J.-M. Zhang, Y. Zhang, K.-W. Xu, and V. Ji, Solid State Commun. 139, 87 (2006).

V. Biju, N. Sugathan, V. Vrinda, and S.L. Salini, J. Mater. Sci. 43, 1175 (2008).

J. Morales, E. Andrade, and M. Miki-Yoshida, Thin Solid Films 366, 16 (2000).

M. Devika, N.K. Reddy, K. Ramesh, K. Gunasekhar, E. Gopal, and K.R. Reddy, J. Electrochem. Soc. 153, G727 (2006).

K. Rogers and P. Daniels, Biomaterials 23, 2577 (2002).

J. Malleshappa, H. Nagabhushana, S.C. Sharma, D.V. Sunitha, N. Dhananjaya, C. Shivakumara, and B.M. Nagabhushana, J. Alloys Compd. 590, 131 (2014).

Y. Rosenberg, V.S. Machavariani, A. Voronel, S. Garber, A. Rubshtein, A. Frenkel, and E. Stern, J. Phys.: Condens. Matter 12, 8081 (2000).

P.K. Jisha, R. Naik, S.C. Prashantha, H. Nagabhushana, S.C. Sharma, H.P. Nagaswarupa, K.S. Anantharaju, B.D. Prasad, and H.B. Premkumar, J. Lumin. 163, 47 (2015).

G.K. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

K.-C. Feng, Y.-H. Su, C.-C. Chou, Z.-M. Liu, and L.-W. Chu, Chin. J. Phys. 50, 932 (2012).

K. Reimann and R. Würschum, J. Appl. Phys. 81, 7186 (1997).

J.F. Nye, Physical Properties of Crystals: Their Representation by Tensors and Matrices (Oxford: Oxford University Press, 1985).

X. He, H. Shen, W. Wang, Z. Wang, B. Zhang, and X. Li, J. Alloys Compd. 556, 86 (2013).

K.A. Aly, N.M. Khalil, Y. Algamal, and Q.M.A. Saleem, J. Alloys Compd. 676, 606 (2016).

M.A. Tagliente and M. Massaro, Nucl. Instrum. Methods Phys. Res., Sect. B 266, 1055 (2008).

A. Khorsand Zak, W.H.A. Majid, M. Ebrahimizadeh Abrishami, R. Yousefi, and R. Parvizi, Solid State Sci. 14, 488 (2012).

Y.T. Prabhu, K.V. Rao, V.S.S. Kumar, and B.S. Kumari, World J. Nano Sci. Eng. 4, 21 (2014).

A. Khorsand Zak, W.H. Abd, M.E.Abrishami Majid, and R. Yousefi, Solid State Sci. 13, 251 (2011).

B. Choudhury and A. Choudhury, Mater. Chem. Phys. 131, 666 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kafashan, H. X-ray Diffraction Line Profile Analysis of Undoped and Se-Doped SnS Thin Films Using Scherrer’s, Williamson–Hall and Size–Strain Plot Methods. J. Electron. Mater. 48, 1294–1309 (2019). https://doi.org/10.1007/s11664-018-6791-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6791-7