Abstract

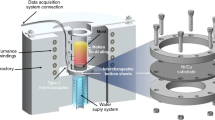

Heat released from aluminum-nickel (Al/Ni) self-propagating exothermic reaction has been developed as a rapid heating source and is called a localized heating source due to its short duration and narrow heat affected zone (HAZ). It is suitable for the interconnection of thermal mismatch material couples, temperature-sensitive devices, microbial systems and microanalysis systems. However, the fusion thickness of the solder layer has not been deeply studied to minimize the HAZ. In this study, Sn was electroplated on the AlNi nanofoil. Experimental and numerical methods were used to evaluate the heating capability of AlNi nanofoil through analyzing the size of fusion zone and HAZ within the Sn solder–AlNi nanofoil–Sn solder sandwich structure. Finite element analysis (FEA) was used for simulating the temperature field and temperature history of the structure. Different thicknesses of tin layer were considered to analyze the effect of the change of structures. The temperature of the surface of the tin layer and fusion zone was measured to validate the FEA model. Furthermore, the analysis showed that the maximum thickness for melting the Sn layer within the substrate–Sn solder–Al/Ni nanofoil–Sn solder–substrate sandwich structure changes with the thickness of substrates and preheating temperature. FEA predictions indicated that a preheating temperature of 125°C is effective to bond Cu substrates at the thickness of 0.3 mm with tin solder.

Similar content being viewed by others

References

A. Duckham, S. Spey, J. Wang, M.E. Reiss, T.P. Weihs, E. Besnoin, and O.M. Knio, J. Appl. Phys. 96, 2336 (2004).

J. Wang, E. Besnoin, A. Duckham, S.J. Spey, M.E. Reiss, and O.M. Knio, J. Appl. Phys. 95, 248 (2004).

A.S. Rogachev, S.G. Vadchenko, F. Baras, O. Politano, S. Rouvimov, N.V. Sachkova, M.D. Grapes, T.P. Weihs, and A.S. Mukasyan, Combust. Flame 166, 158 (2016).

J. Braeuer, J. Besser, M. Wiemer, and T. Gessner, in Solid-State Sensors, Actuators and Microsystems Conference (2011), pp. 1332–1335.

J. Zhang, F.S. Wu, J. Zou, and B. An, in International Conference on Electronic Packaging Technology (2009), pp. 838–842.

R. Grieseler, T. Welker, J. Müller, and P. Schaaf, Phys. Status Solidi A 209, 512 (2012).

B. Boettge, J. Braeuer, M. Wiemer, M. Petzold, J. Bagdahn, and T. Gessner, J. Micromech. Microeng. 20, 064018 (2010).

G.D. Theodossiadis and M.F. Zaeh, Prod. Eng. Res. Devel. 11, 401 (2017).

J. Fan, T. Shi, X. Tao, T. Zhou, J. Li, Z. Tang, G. Liao, and X. Yu, J. Alloys Compd. 735, 1189 (2018).

X. Qiu and J. Wang, Sens. Actuators A 141, 476 (2008).

T. Namazu and S. Inoue, Mater. Sci. Forum 638, 2142 (2010).

H.R. Ma, Y.P. Wang, J. Chen, H.T. Ma, and N. Zhao, in International Conference on Electronic Packaging Technology (2017), pp. 1402–1405.

F. Sun, Y. Zhu, and X. Li, J. Electron. Mater. 46, 1 (2017).

L. Sun, L. Zhang, S.J. Zhong, J. Ma, and L. Bao, J. Mater. Sci. Mater. Electron. 26, 9164 (2015).

W. Zhu, F.S. Wu, B. Wang, E. Hou, P. Wang, C. Liu, and W.S. Xia, Microelectron. Eng. 128, 24 (2014).

A.J. Gavens, D. Van Heerden, A.B. Mann, M.E. Reiss, and T.P. Weihs, J. Appl. Phys. 87, 1255 (2000).

R. Pretorius, A.M. Vredenberg, F.W. Saris, and R. De, Reus. J. Appl. Phys. 70, 3636 (1991).

Y. Wang, Z.K. Liu, and L.Q. Chen, Acta Mater. 52, 2665 (2004).

G.D. Theodossiadis, and M.F. Zaeh, Prod. Eng. Res. Devel. 11, 373 (2017).

R.C. Armstrong and M.L. Koszykowski, Combust. Flame 72, 13 (1988).

D.A. Frank-Kamenetskiĭ, Diffusion and Heat Transfer in Chemical Kinetics (New York: Plenum Press, 1969).

Acknowledgments

The authors acknowledge the financial support provided by the National Nature Science Foundation of China (NSFC No. 61574068), the Fundamental Research Funds for the Central Universities (No. 2016JCTD112) and the Research Grants Council (RGC) Joint Research project (RGC NO. CityU101/12). In addition, the authors thank Huazhong University of Science and Technology Analytical and Testing Center, State Key Laboratory of Material Processing and Die & Mould Technology for SEM analyze.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Z., Mo, L., Liu, H. et al. Study of Fusion Thickness of Tin Solder Heating by Self-Propagating Exothermic Reaction. J. Electron. Mater. 47, 7435–7448 (2018). https://doi.org/10.1007/s11664-018-6684-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-018-6684-9