Abstract

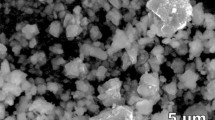

A functionally graded material (FGM) in terms of grain size gradation is fabricated using zinc oxide (ZnO) with spark plasma sintering and an additive manufacturing technique by diffusion bonding layers of material sintered at different temperatures to achieve a thermoelectric generator (TEG) material that can dissipate heat well and retain high energy conversion efficiency for longer-lasting and comparably efficient TEGs. This FGM is compared to a previously made FGM with continuous grain size gradation. Uniform and graded grain size conditions are modeled for thermoelectric output by using thermoelectric properties of the uniform grain size as well as the varying properties seen in the FGMs. The actual thermoelectric output of the samples is measured and compared to the simulations. The grain size has a large effect on the efficiency and efficiency range. The samples are thermally cycled with a fast heating rate to test the thermal stress robustness and degradation, and the resistance at the highest temperature is measured to indicate degradation from thermal stress. The measured efficiency after cycling shows that the FGMs survive longer lifetime than that with uniform small grains.

Similar content being viewed by others

References

Y. Hori, D. Kusano, T. Ito, and K. Izumi, in Eighteenth International Conference on Thermoelectrics, pp. 328–331 (1999).

L. Bakhtiaryfard and Y.S. Chen, Adv. Mech. Eng. 7, 152419 (2015).

Y. Obata and N. Noda, J. Therm. Stress. 17, 471 (1994).

D.P.H. Hasselman and G.E. Youngblood, J. Am. Ceram. Soc. 61, 49 (1978).

A. Kawasaki and R. Watanabe, Ceram. Trans. Funct. Gradient Mater. 34, 157 (1993).

H. Takahashi, T. Ishikawa, D. Okugawa, and T. Hashida, Therm. Shock Therm. Fatigue Behav. Adv. Ceram. 241, 543 (1993).

I. Shiota and I. A. Nishida, in XVI International Conference on Thermoelectrics, pp. 364–370 (1997).

Z. Balak, M. Azizieh, H. Kafashan, M.S. Asl, and Z. Ahmadi, Mater. Chem. Phys. 196, 333 (2017).

A.S. Al-Merbati, B.S. Yilbas, and A.Z. Sahin, Appl. Therm. Eng. 50, 683 (2013).

U. Erturun, K. Erermis, and K. Mossi, Appl. Therm. Eng. 73, 128 (2014).

Z.-H. Jin and G.H. Paulino, Int. J. Fract. 107, 73 (2001).

B.L. Wang, Y.B. Guo, and C.W. Zhang, Eng. Fract. Mech. 152, 1 (2016).

M. Sribalaji, B. Mukherjee, S.R. Bakshi, P. Arunkumar, K. Suresh Babu, and A.K. Keshri, Compos. Part B Eng. 123, 227 (2017).

E. Hatzikraniotis, K.T. Zorbas, I. Samaras, T. Kyratsi, and K.M. Paraskevopoulos, J. Electron. Mater. 39, 2112 (2010).

Z. Li, J. Liu, H. Du, S. Li, and P. Zhang, Mater. Sci. Eng. A 517, 154 (2009).

X.Q. You, T.Z. Si, N. Liu, P.P. Ren, Y.D. Xu, and J.P. Feng, Ceram. Int. 31, 33 (2005).

K.H. Kim, S.H. Shim, K.B. Shim, K. Niihara, and J. Hojo, J. Am. Ceram. Soc. 88, 628 (2005).

Y. Kinemuchi, M. Mikami, K. Kobayashi, K. Watari, and Y. Hotta, J. Electron. Mater. 39, 2059 (2009).

S. Walia, S. Balendhran, H. Nili, S. Zhuiykov, G. Rosengarten, Q.H. Wang, M. Bhaskaran, S. Sriram, M.S. Strano, and K. Kalantar-zadeh, Prog. Mat. Sci. 58, 1443 (2013).

M. Arai, M. Kambe, T. Ogata, and Y. Takahashi, Trans. Jpn. Soc. Mech. Eng. Ser. A 62, 488 (1996).

C.L. Cramer, J. Gonzalez-Julian, P.S. Colasuonno, and T.B. Holland, J. Eur. Ceram. Soc. 37, 4693 (2017).

E. Müller, Č. Drašar, J. Schilz, and W.A. Kaysser, Mater. Sci. Eng. A 362, 17 (2003).

Z. Dashevsky, Y. Gelbstein, I. Edry, I. Drabkin, and M.P. Dariel, in Twenty-Second International Conference on Thermoelectrics, pp. 421–424 (2003).

A.E. Kaliazin, V.L. Kuznetsov, and D.M. Rowe, in Twentieth International Conference on Thermoelectrics, pp. 286–292 (2001).

M. He, Y. Zhao, B. Wang, Q. Xi, J. Zhou, and Z. Liang, Small 11, 5889 (2015).

A. El-Desouky, M. Carter, M.A. Andre, P.M. Bardet, and S. LeBlanc, Mater. Lett. 185, 598 (2016).

G.C. Catlin, R. Tripathi, G. Nunes, P.B. Lynch, H.D. Jones, and D.C. Schmitt, J. Power Sources 343, 316 (2017).

M. Søndergaard, E.D. Bøjesen, K.A. Borup, S. Christensen, M. Christensen, and B.B. Iversen, Acta Mater. 61, 3314 (2013).

W. Seifert, K. Zabrocki, E. Müller, and G.J. Snyder, Phys. Status Solidi A 207, 2399 (2010).

Z.-H. Jin, T.T. Wallace, R.J. Lad, and J. Su, J. Electron. Mater. 43, 308 (2013).

Z.-H. Jin and T.T. Wallace, J. Electron. Mater. 44, 1444 (2015).

T.T. Wallace, Z.-H. Jin, and J. Su, J. Electron. Mater. 45, 1 (2016).

T.H. Cross and M.J. Mayo, Nanostructured Mater. 3, 163 (1993).

L. Liu, F. Ye, Y. Zhou, Z. Zhang, and Q. Hou, J. Eur. Ceram. Soc. 30, 2683 (2010).

B. Dargatz, J. Gonzalez-Julian, M. Bram, Y. Shinoda, F. Wakai, and O. Guillon, J. Eur. Ceram. Soc. 36, 1207 (2016).

B. Dargatz, J. Gonzalez-Julian, M. Bram, Y. Shinoda, F. Wakai, and O. Guillon, J. Eur. Ceram. Soc. 36, 1221 (2016).

H.G. Jensen, Am. J. Phys. 38, 870 (1970).

B.M. Gol’tsman and M.G. Komissarchik, J. Eng. Phys. 20, 385 (1971).

M.T. Barako, W. Park, A.M. Marconnet, M. Asheghi, and K.E. Goodson, J. Electron. Mater. 42, 372 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cramer, C.L., Li, W., Jin, ZH. et al. Techniques for Mitigating Thermal Fatigue Degradation, Controlling Efficiency, and Extending Lifetime in a ZnO Thermoelectric Using Grain Size Gradient FGMs. J. Electron. Mater. 47, 866–872 (2018). https://doi.org/10.1007/s11664-017-5879-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-017-5879-9