Abstract

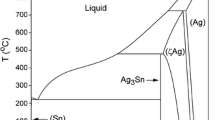

Samples extracted along the length of directionally solidified (DS) castings of three Sn-xBi alloys (x = 34 wt.%Bi, 52 wt.%Bi and 58 wt.%Bi) were first evaluated metallographically and then subjected to scanning electron microscopy and energy-dispersive x-ray spectroscopy analyses. The characteristic length scale of both eutectic and dendritic phases forming the microstructure were determined and correlated with solidification thermal parameters (growth rate V, and cooling rate Ṫ). Tensile and Vickers hardness tests were performed to allow strength and ductility to be discussed as a function of both microstructure features and alloy solute content. The tertiary dendrite arm spacings along the length of the DS Sn-52 wt.%Bi alloy casting are shown to be lower than those obtained for the Sn-34 wt.%Bi alloy casting. The results of mechanical tests show that, with the decrease in the alloy Bi content, both tensile strength and hardness are improved. This is shown to be mainly attributed to the higher density of Bi precipitates decorating the Sn-rich dendrites, which are finer than the equivalent phase developed for the Sn-52 wt.%Bi alloy. However, the ductility is shown to be significantly improved for specimens associated with regions of more refined microstructure of the Sn-52 wt.%Bi alloy DS casting. A microstructure combining much branched dendrites, fine Bi particles within the β-Sn dendritic matrix and an important proportion of very fine eutectic formed by alternate Bi-rich and Sn-rich phase, seems to be conducive to this higher ductility. In this case, the fracture surface is shown to be more finely broken with presence of dimples for this particular condition, i.e., characteristic of a ductile fracture mode.

Similar content being viewed by others

References

M.H. Braga, J. Vizdal, A. Kroupa, J. Ferreira, D. Soares, and L.F. Malheiros, CALPHAD 31, 468 (2007).

R.M. Shalaby, Mater. Sci. Eng. A 560, 86 (2013).

Y. Goh, A.S.M.A. Haseeb, and M.F.M. Sabri, Electrochim. Acta 90, 265 (2013).

P. Vianco, J. Rejent, and R. Grant, Mater. Trans. 45, 765 (2004).

X. Chen, J. Zhou, F. Xue, and Y. Yao, Mater. Sci. Eng. A 662, 251 (2016).

H. Sun, Q. Li, and Y.C. Chan, J. Mater. Sci. Mater. Electron. 25, 4380 (2014).

L. Shen, Z.Y. Tan, and Z. Chen, Mater. Sci. Eng. A 561, 232 (2013).

Y. Peng and K. Deng, J. Alloys Compd. 625, 44 (2015).

R. Dai, S.G. Zhang, and J.G. Li, J. Electron. Mater. 40, 2458 (2011).

Z. Mei and J.W. Morris Jr., J. Electron. Mater. 21, 599 (1992).

J.L.F. Goldstein and J.W. Morris Jr., J. Electron. Mater. 23, 477 (1994).

F. Hua, Z. Mei, and J. Glazer, Electronic Components; Technology Conference, 48th IEEE, p. 277 (1998).

T.H. Chuang and H.F. Wu, J. Electron. Mater. 40, 71 (2011).

H. Xiaowu, L. Ke, and A. Fanrong, China Foundry 9, 360 (2012).

J. Glazer, Inter. Mater. Rev. 40, 65 (1995).

E.P. Wood and K.L. Nimmo, J. Electron. Mater. 23, 709 (1994).

J.F. Li, S.H. Mannan, M.P. Clode, D.C. Whalley, and D.A. Hutt, Acta Mater. 54, 2907 (2006).

J.W. Yoon, C.B. Lee, and S.B. Jung, Mater. Trans. A 43, 1712 (2002).

K.W. Moon, W.J. Boettinger, U.R. Kattner, C.A. Handwerker, and D.J. Lee, J. Electron. Mater. 30, 45 (2001).

X.Y. Liu, H.T. Ma, J. Zhao, and L. Wang, Conference on High Density Microsystem Design and Packaging and Component Failure Analysis, 1 (2005).

A. Torres, L. Hernández, and O. Domínguez, Mater. Sci. Appl. 3, 355 (2012).

M.N. Croker, R.S. Fidler, and R.W. Smith, Proc. R. Soc. Lond. A 335, 15 (1973).

M.X.F. Gigliotti, L.F.P. Graham, and G.A. Colligan, Metall. Trans. 1, 1038 (1970).

Z. Lai and D. Ye, J. Mater. Sci. Mater. Electron. 27, 3182 (2016).

M. McCormack, H.S. Chen, G.W. Kammlott, and S. Jin, J. Electron. Mater. 26, 954 (1997).

U. Böyük and N. Maraşli, Mater. Chem. Phys. 119, 442 (2010).

P.D. Pereira, J.E. Spinelli, and A. Garcia, Mater. Des. 45, 377 (2013).

W.R. Osório, D.R. Leiva, L.C. Peixoto, L.R. Garcia, and A. Garcia, J. Alloys Compd. 562, 194 (2013).

W.R. Osório, L.C. Peixoto, L.R. Garcia, N. Mangelinck-Noël, and A. Garcia, J. Alloys Compd. 572, 97 (2013).

O.V. Gusakova, V.G. Shepelevich, and L.P. Shcherbachenko, J. Surf. Investig.-X-Ray 10, 146 (2016).

A.P. Silva, J.E. Spinelli, and A. Garcia, J. Alloys Compd. 475, 347 (2009).

J.E. Spinelli, N. Cheung, P.R. Goulart, J.M.V. Quaresma, and A. Garcia, Int. J. Therm. Sci. 51, 145 (2012).

P.R. Goulart, J.E. Spinelli, and N. Cheung, Mater. Chem. Phys. 119, 272 (2010).

M. Gunduz and E. Çadirli, Mater. Sci. Eng. A 327, 167 (2002).

J.E. Spinelli, B. Silva, and A. Garcia, Mater. Des. 58, 482 (2014).

L. Shen, P. Septiwerdani, and Z. Chen, Mater. Sci. Eng. A 558, 253 (2012).

O. Mokhtari and H. Nishikawa, Mater. Sci. Eng. A 651, 831 (2016).

K.A. Jackson and J.D. Hunt, Trans. Metall. Soc. AIME 236, 1129 (1966).

B. Silva, H. Nguyen-Thi, G. Reinhart, N. Mangelinck-Nöel, A. Garcia, and J.E. Spinelli, Mater. Charact. 107, 43 (2015).

A. Garcia and M. Prates, Metall. Trans. B 9, 449 (1978).

A. Garcia, T.W. Clyne, and M. Prates, Metall. Trans. B 10, 85 (1979).

L.R. Garcia, W.R. Osório, L.C. Peixoto, and A. Garcia, Mater. Charact. 61, 212 (2010).

J.E. Spinelli, B.L. Silva, and A. Garcia, J. Electron. Mater. 43, 1347 (2014).

D. Bouchard and J.S. Kirkaldy, Metall. Mater. Trans. B 28, 651 (1997).

C.H. Raeder, D. Mitlin, and R.W. Messler Jr, J. Mater. Sci. 33, 4503 (1998).

Acknowledgements

The authors acknowledge the financial support provided by FAPESP (São Paulo Research Foundation, Brazil: Grants 2015/11863-5 and 2013/08259-3), CNPq and CAPES-COFECUB (Grant 857/15).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, B.L., da Silva, V.C.E., Garcia, A. et al. Effects of Solidification Thermal Parameters on Microstructure and Mechanical Properties of Sn-Bi Solder Alloys. J. Electron. Mater. 46, 1754–1769 (2017). https://doi.org/10.1007/s11664-016-5225-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5225-7