Abstract

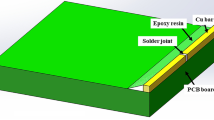

Solder joints with Cu/Sn-Ag/Cu structure and bump height of 15 μm have been used to investigate the electromigration phenomenon at different temperatures and current densities. Moreover, the grain orientation was analyzed using electron backscatter diffraction. It was found that the anisotropic properties of tin affected the formation rate of Cu-Sn intermetallic compounds (IMCs), and that the angle between the electron flow direction and tin grain orientation played an important role in the formation of Cu6Sn5 IMC. With changes in angle, the diffusion rate of copper atoms in tin also varied. When the c-axis of tin was parallel to the electron flux, copper atoms diffused rapidly, resulting in fast formation of Cu-Sn IMCs. On the other hand, if the angle between the c-axis of the grain and the electron flow direction was large, the tin grains were more resistant to Cu diffusion during current stressing, leading to a very slow IMC formation rate.

Similar content being viewed by others

References

P.E. Garrou, C.A. Bower, and P. Ramm, Handbook of 3D Integration: Technology and Applications of 3D Integrated Circuits (Weinheim: Wiley-VCH, 2008).

K.N. Tu, Microelectron. Reliab. 51, 517 (2011).

C. Chen, D. Yu, and K.N. Chen, MRS Bull. 40, 257 (2015).

Y.W. Chang, C. Chen, T.C. Chang, C.J. Zhan, J.Y. Juang, and A.T. Huang, Mater. Lett. 137, 136 (2014).

Y.W. Chang, H.Y. Peng, R.W. Yang, C. Chen, T.C. Chang, C.J. Zhan, J.Y. Juang, and A.T. Huang, Microelectron. Reliab. 53, 41 (2013).

K.N. Tu, Microelectron. Reliab. 53, 1 (2013).

T.C. Huang, T.L. Yang, J.H. Ke, C.H. Hsueh, and C.R. Kao, Scr. Mater. 80, 37 (2014).

D.C. Yeh and H.B. Huntington, Phys. Rev. Lett. 53, 1469 (1984).

M.H. Lu, D.Y. Shih, P. Lauro, C. Goldsmith, and D.W. Henderson, Appl. Phys. Lett. 92, 211909 (2008).

A. Tasooji, L. Lara, and K. Lee, J. Electron. Mater. 43, 4386 (2014).

C. Kinney, X. Linares, K.O. Lee, and J.W. Morris Jr, J. Electron. Mater. 42, 607 (2013).

T.L. Yang, J.J. Yu, C.C. Li, Y.F. Lin, and C.R. Kao, J. Alloys Compd. 627, 281 (2015).

S.W. Liang, Y.W. Chang, and C. Chen, J. Electron. Mater. 36, 1348 (2007).

T. Tian, A. M. Gusak, O. Y. Liashenko, J. K. Han, D. Choi, and K. N. Tu, in Proceeding of IEEE 62nd Electron. Components and Technology Conference, vol. 741 (2012). doi:10.1109/ECTC.2012.6248915.

K.N. Tu, J.W. Mayer, and L.C. Feldman, Electronic Thin Film Science: For Electrical Engineers and Materials Scientists (New York: Macmillan, 1992).

J.Q. Chen, J.D. Guo, K.L. Liu, and J.K. Shang, J. Appl. Phys. 114, 153509 (2013).

C.C. Wei, C.F. Chen, P.C. Liu, and C. Chen, J. Appl. Phys. 105, 023715 (2009).

C. Chen, H.M. Tong, and K.N. Tu, Annu. Rev. Mater. Res. 40, 531 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, MY., Lin, Hw. & Chen, C. Effect of Sn Grain Orientation on Formation of Cu6Sn5 Intermetallic Compound Under Current Stressing. J. Electron. Mater. 46, 2179–2184 (2017). https://doi.org/10.1007/s11664-016-5154-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-5154-5