Abstract

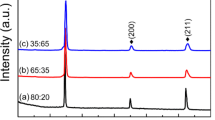

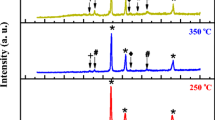

Fe-Co nanoparticles were prepared by mechanical alloying in air with various milling times from 0 h to 10 h and annealing temperatures in the range from 773 K to 973 K. The combined use of both conventional x-ray diffraction (XRD) and synchrotron x-ray absorption spectroscopy (XAS) techniques allowed us to obtain accurate data on the phase formation and the oxidation state of the materials. XRD patterns reveal a secondary phase of Fe3O4 that is present in as-milled samples and those annealed in Ar + H2 (5%) at temperatures of up to 600°C. This secondary phase disappeared for annealing temperatures of over 700°C. Meanwhile, analyses of Fe K-edge x-ray absorption near-edge structure (XANES) and extended x-ray absorption fine structure (EXAFS) spectra clearly showed that the local structure around Fe of all samples were of a bcc structure and had the oxidation state of +0. Most importantly, the ratio of bcc and hcp structures was also extracted from the Co K-edge XANES and the measured K-weighted EXAFS spectra of the alloyed Fe-Co samples. Moreover, magnetization measurements at room temperature indicated that the saturation magnetization (M s) increased with increasing milling time and annealing temperature. While the former behavior is assigned to the Fe-Co alloy formation, we believe the effects of reducing the oxidation of the annealed samples to be the major cause of the enhanced M s. The dependence of coercivity (H c) on milling time and annealing temperature was also investigated and discussed.

Similar content being viewed by others

References

N. Poudyal, C. Rong, Y. Zhang, D. Wang, M.J. Kramer, R.J. Hebertc, and J.P. Liu, J. Alloys Compd. 521, 55 (2012).

Y.X. Gong, L. Zhen, J.T. Jiang, C.Y. Xu, and W.Z. Shao, J. Magn. Magn. Mater. 321, 3702 (2009).

S.D. Bader, Rev. Mod. Phys. 78, 1 (2006).

A.H. Lu, E.L. Salabas, and F. Schuth, Angew. Chem. Int. Ed. 46, 1222 (2007).

Q.A. Pankhurst, J. Connolly, S.K. Jones, and J. Dobson, J. Phys. D Appl. Phys. 36, R167 (2003).

M. Abbas, M.N. Islam, B.P. Rao, T. Ogawa, M. Takahashi, and C.G. Kim, Mat. Lett. 91, 326 (2013).

Q. Zeng, I. Baker, V. McCreary, and Z. Yan, J. Magn. Magn. Mater. 318, 28 (2007).

A. Zelenakova, D. Oleksakova, J. Degmova, J. Kovac, P. Kollar, M. Kusy, and P. Sovak, J. Magn. Magn. Mater. 316, e519 (2007).

M. Sorescu and A. Grabias, Intermetallics 10, 317 (2002).

M. Hesani, A. Yazdani, B. Abedi Ravan, and M. Ghazanfari, Sol. Stat. Commun. 150, 594 (2010).

V. Mancier, J.L. Delplancke, J. Delwiche, M.J. Hubin-Franskin, C. Piquer, L. Rebbouh, and F. Grandjean, J. Magn. Magn. Mater. 281, 27 (2004).

Y.D. Kim, J.Y. Chung, J. Kim, and H. Jeon, Mater. Sci. Eng., A 291, 17 (2000).

D.K. Tung, D.H. Manh, P.T. Phong, L.T.H. Phong, N.V. Dai, D.N.H. Nam, and N.X. Phuc, J. Alloys Compd. 640, 34 (2015).

D.H. Manh, T.D. Thanh, N.X. Phuc, L.V. Hong, P.T. Phong, and L.T. Hung, Int. J. Nanotechnol. 8, 241 (2011).

P. Sirvent, E. Berganza, A.M. Aragón, A. Bollero, A. Moure, M. García-Hernández, P. Marín, J.F. Fernández, and A. Quesada, J. Appl. Phys. 115, 17B505 (2014).

D.H. Manh, D.K. Tung, D.N.H. Nam, L.V. Hong, P.T. Phong, N.X. Phuc, I.E.E.E. Trans, Magn. 50, 2005104 (2014).

D. Carta, G. Mountjoy, M. Gass, G. Navarra, M.F. Casula, and A. Corrias, J. Chem. Phys. 127, 204705 (2007).

S.N. Ehrlich, J.C. Hanson, A. LopezCamara, L. Barrio, M. Estrella, G. Zhou, R. Si, S. Khalid, and Q. Wang, Nuc. Instr. Meth. Phys. Res. Sec A. 649, 213 (2011).

B. Ravel and M. Newville, J. Synchrotron Radiat. 12, 537 (2005).

S. Azzaza, S. Alleg, H. Moumeni, A.R. Nemamcha, J.L. Rehspringer, and J.M. Greneche, J. Phys. 18, 7257 (2006).

D.-S. Yang, S.-H. Kim, Y.-G. Yoo, and S.-C. Yu, J. Phys 190, 012139 (2009).

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990).

D.H. Manh, D.K. Tung, L.T.H. Phong, P.T. Thanh, and N.X. Phuc, JPS Conf. Proc. 1, 012010 (2014).

K. Akkouche, A. Guittoum, N. Boukherroub, and N. Souami, J. Magn. Magn. Mater. 323, 2542 (2011).

Acknowledgements

This research is funded by the Vietnam National Foundation for Science and Technology Development (NAFOSTED) under Grant Number 103.02-2012.09. The authors are also thankful to the Institute of Materials Science (IMS) National Key Laboratory for Electronic Materials and Devices.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manh, D.H., Tung, D.K., Phong, L.T.H. et al. Complementary Studies of Phase Formation During Fabrication of Fe0.65Co0.35 Nanoparticles by Mechanical Alloying. J. Electron. Mater. 45, 2501–2507 (2016). https://doi.org/10.1007/s11664-016-4392-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4392-x