Abstract

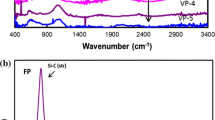

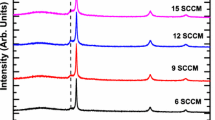

Silicon carbide (SiC) thin films have been deposited using a hot-wire chemical vapor deposition technique on quartz substrates with a mixture of silane, methane, and hydrogen gases as precursors at a reasonably high deposition rate of approximately 15 nm/min to 50 nm/min. The influence of the filament temperature (T F) on the structural, optical, and electrical properties of the SiC film has been investigated using x-ray diffraction, Raman scattering, Fourier-transform infrared spectroscopy, x-ray photoelectron spectroscopy, ultraviolet–visible–near infrared transmission spectroscopy, and dark conductivity (σ d) studies. Films deposited at low T F (1800°C to 1900°C) are amorphous in nature with high density of Si–Si bonds, whereas high-T F (≥2000°C) films are nanocrystalline embedded in an amorphous SiC matrix with higher concentration of Si–C bonds and negligible concentration of Si–Si bonds. The bandgap (E g) varies from 2.5 eV to 3.1 eV and σ d (50°C) from ∼10−9 Ω−1 cm−1 to 10−1 Ω−1 cm−1 as T F is increased from 1900°C to 2200°C. This increase in E g and σ d is due to microstructural changes and unintentional oxygen doping of the films.

Similar content being viewed by others

References

H. Morkoc, S. Strite, G.B. Gao, M.E. Lin, B. Sverdlov, and M. Burns, J. Appl. Phys. 76, 1363 (1994).

W.J. Choyke, H. Matsunami, and G. Pensl, Silicon Carbide: Recent Major Advances, 2nd ed. (New York: Springer, 2003), p. 4.

F. Nava, G. Bertuccio, A. Cavallini, and E. Vittones, Meas. Sci. Technol. 19, 102001 (2008).

I.A. Yunaz, K. Hashizume, S. Miyajima, A. Yamada, and M. Konagai, Sol. Energy Mater. Sol. Cells 93, 1056 (2009).

Y. Huang, A. Dasgupta, A. Gordijn, F. Finger, and R. Carius, Appl. Phys. Lett. 90, 203502 (2007).

F. Finger, O. Astakhov, T. Bronger, R. Carius, T. Chen, A. Dasgupta, A. Gordijn, L. Houben, Y. Huang, and S. Klein, Thin Solid Films 517, 3507 (2009).

T. Chen, Y. Huang, D. Yang, R. Carius, and F. Finger, Thin Solid Films 519, 4523 (2011).

S. Miyajima, K. Haga, A. Yamada, and M. Konagai, Jpn. J. Appl. Phys. 45, L432 (2006).

C. Ehling, J.H. Werner, and M.B. Schubert, Phys. Status Solidi C7, 1016 (2010).

H. Hobert, H.H. Dunken, G. Peiter, W. Stier, M. Diegel, and H. Stafast, Appl. Phys. A Mater. Sci. Process. 69, 69 (1999).

W.K. Choi, F.L. Loo, F.C. Loh, and K.L. Tan, J. Appl. Phys. 80, 1611 (1996).

T. Rajagopalan, X. Wang, B. Lahlouh, C. Ramkumar, P. Dutta, and S. Gangopadhyay, J. Appl. Phys. 94, 5252 (2003).

S. Miyajima, M. Sawamura, A. Yamada, and M. Konagai, Jpn. J. Appl. Phys. 47, 3368 (2008).

Alka Kumbhar, S.B. Patil, S. Kumar, R. Lal, and R.O. Dusane, Thin Solid Films 395, 244 (2001).

S. Klein, R. Carius, F. Finger, and L. Houben, Thin Solid Films 501, 169 (2006).

T. Chen, F. Köhler, A. Heidt, Y. Huang, F. Finger, and R. Carius, Thin Solid Films 519, 4511 (2011).

H. Matsumura, Jpn. J. Appl. Phys. 37, 3175 (2003).

S. Asari, T. Fujinaga, M. Takagi, M. Hashimoto, K. Saito, M. Harada, and M. Ishikawa, Thin Solid Films 516, 541 (2008).

Y. Komura, A. Tabata, T. Narita, and A. Kondo, Thin Solid Films 516, 633 (2008).

Y. Komura, A. Tabata, T. Narita, M. Kanaya, A. Kondo, and T. Mizutani, Jpn. J. Appl. Phys. 46, 45 (2007).

Y. Hoshide, Y. Komura, A. Tabata, A. Kitagawa, and A. Kondo, Thin Solid Films 517, 3520 (2009).

T. Itoh, Y. Katoh, T. Fujiwara, K. Fukunaga, S. Nonomura, and S. Nitta, Thin Solid Films 395, 240 (2001).

A. Tabata and Y. Komura, Surf. Coat. Technol. 201, 8986 (2007).

Purabi Gogoi, Himanshu S. Jha, and Pratima Agarwal, Thin Solid Films 518, 6818 (2010).

Akimori Tabata and Akinori Naito, Thin Solid Films 519, 4451 (2011).

Y. Komura, A. Tabata, T. Naritu, A. Kondo, and T. Mizutani, J. Non-Cryst. Solids 352, 1367 (2006).

Q. Cheeng, S. Xu, J.W. Chai, S.Y. Huang, Y.P. Ren, J.D. Long, P.P. Rutkevych, and K. Ostrikov, Thin Solid Films 516, 5991 (2008).

J. Gubicza, S. Nauyoks, L. Balogh, J. Labar, T.W. Zerdaa, and T. Ungár, J. Mater. Res. 22, 1314 (2007).

A. Dasgupta, S. Klein, L. Houben, R. Carius, F. Finger, and M. Luysberg, Thin Solid Films 516, 618 (2008).

R.J. Nemanish, J.T. Glass, G. Lucovosky, and R.E. Schorder, J. Vac. Sci. Technol. A6, 1783 (1988).

W.K. Choi, T.Y. Ong, L.S. Tan, F.C. Loh, and K.L. Tan, J.␣Appl. Phys. 83, 4968 (1998).

S. Ray, D. Das, and A.K. Barua, Sol. Energy Mater. 15, 45 (1987).

H. Shanks, C.J. Faug, L. Ley, M. Cardona, F.J. Demand, and S. Kalbitzer, Phys. Status Solidi B 100, 43 (1980).

A. Matsuda and J. Non-Cryst, Solids 338–340, 1 (2004).

B.P. Swain, Surf. Coat. Technol. 201, 1589 (2006).

J.F. Moulder, W.F. Stickle, P.E. Sobol, and K.D. Bomber, Handbook of X-ray Photoelectron Spectroscopy, 2nd ed. (Eden Prairie: Perkin-Elmer, 1992), p. 252.

J. Tauc, R. Grigorovici, and A. Vancu, Phys. Status Solidi B 15, 627 (1966).

S. Kerdiles, R. Madelon, and R. Rizk, Appl. Surf. Sci. 184, 150 (2001).

A. Dasgupta, Y. Huang, L. Houben, S. Klein, F. Finger, R. Carius, and M. Luysberg, Thin Solid Films 516, 622 (2008).

R. Swanepoel, J. Phys. E 16, 1214 (1983).

Acknowledgements

The work reported here is supported by the Board for Research in Fusion Science & Technology (BRFST). We are very grateful to Dr. D.M. Phase, UGC-DAE Consortium for Scientific Research, Indore for XPS measurements, Dr. Manoranjan Kar, Department of Physics, IIT Patna for XRD measurements, and the Central Instrument Facility, IIT Guwahati for Raman measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jha, H.S., Yadav, A., Singh, M. et al. Growth of Wide-Bandgap Nanocrystalline Silicon Carbide Films by HWCVD: Influence of Filament Temperature on Structural and Optoelectronic Properties. J. Electron. Mater. 44, 922–928 (2015). https://doi.org/10.1007/s11664-014-3580-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3580-9