Abstract

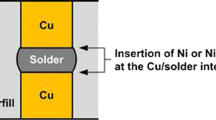

In flip chip applications, Cu pillars with solder caps are regarded as next-generation electronic interconnection technology, because of high input/output density. However, because of diffusion and reaction of Sn and Cu during the high-temperature reflow process, intermetallic compounds (IMC) are formed, and grow, at the interface between the cap and the pillar. Understanding the growth behavior of interfacial IMC is critical in the design of solder interconnections, because excessive growth of IMC can reduce the reliability of connections. In this study, the growth of IMC during thermal cycling, an accelerated method of testing the service environment of electronic devices, was studied by use of focused ion beam–scanning electron microscopy. Under alternating high and low-temperature extremes, growth of Cu6Sn5 (η-phase) and Cu3Sn (ε-phase) IMC was imaged and measured as a function of the number of cycles. The total IMC layer grew significantly thicker but became more uniform during thermal cycling. The Cu3Sn layer was initially thinner than the Cu6Sn5 layer but outgrew the Cu6Sn5 layer after 1000 cycles. It was found that, with limited Cu and Sn diffusion, consumption of Cu6Sn5 for growth of the Cu3Sn layer can result in a thinner Cu6Sn5 layer after thermal cycling.

Similar content being viewed by others

References

R. Asgari, 27th Annual IEEE/SEMI International, (2002), pp. 18–22.

J.H. Lau, Flip Chip Technologies (McGraw-Hill Professional, 1995), pp. 25–28.

V. Eveloy, S. Ganesan, Y. Fukuda, J. Wu, and M.G. Pecht, IEEE Trans. Compon. Packag. Technol. 28, 884–894 (2005).

B. Kim and T. Ritzdorf, J. Electrochem. Soc. 150, C577–C584 (2003).

M. Datta, Electrochim. Acta 48, 2975–2985 (2003).

C.E. Ho, S.C. Yang, and C.R. Kao, Lead-Free Electronic Solders, (Berlin: Springer, 2007), pp. 155–174.

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R 27, 95–141 (2000).

F. Wafula, L. Yin, P. Borgesen, D. Andala, and N. Dimitrov, J. Electron. Mater. 41, 1898–1906 (2012).

L. Yin, F. Wafula, N. Dimitrov, and P. Borgesen, J. Electron. Mater. 41, 302–312 (2012).

H. Xiao, X.Y. Li, Y.X. Zhu, J.L. Yang, J. Chen, and F. Guo, J.␣Mater. Sci. Mater. Electron. 24, 2527–2536 (2013).

J.-W. Yoon, B.-I. Noh, Y.-H. Lee, H.-S. Lee, and S.-B. Jung, Microelectron. Reliab. 48, 1864–1874 (2008).

A. Choubey, H. Yu, M. Osterman, M. Pecht, F. Yun, L. Yonghong, and X. Ming, J. Electron. Mater. 37, 1130–1138 (2008).

X.Y. Li, F.H. Li, F. Guo, and Y.W. Shi, J. Electron. Mater. 40, 51–61 (2011).

J. S. S. T. ASSOCIATION, (2005).

J.-C. Lin, W. Heeschen, J. Reffner, and J. Hook, Microsc. Microanal. 18, 266–271 (2012).

W.S. Rasband, U. S. National Institutes of Health, Bethesda, Maryland, USA, http://imagej.nih.gov/ij/, 1997–2012.

B. Ebersberger and C. Lee, ECTC, (2011).

H.F. Zou, Q.K. Zhang, and Z.F. Zhang, J. Electron. Mater. 40, 1542–1548 (2011).

G. Zeng, S.B. Xue, L. Zhang, L.L. Gao, W. Dai, and J.D. Luo, J. Mater. Sci. Mater. Electron. 21, 421–440 (2010).

K.S. Kim, S.H. Huh, and K. Suganuma, Mater. Sci. Eng. A 333, 106–114 (2002).

B.J. Kim, G.T. Lim, J. Kim, K. Lee, Y.B. Park, and Y.C. Joo, Electron. Compon. C, pp. 336–340 (2008).

J. Shen, M. Zhao, P. He, and Y. Pu, J. Alloy Compd. 574, 451–458 (2013).

H.K. Kim and K.N. Tu, Phys. Rev. B 53, 16027–16034 (1996).

P.L. Tu, Y.C. Chan, K.C. Hung, and J.K.L. Lai, Scripta Mater. 44, 317–323 (2001).

B. Chao, S.H. Chae, X.F. Zhang, K.H. Lu, J. Im, and P.S. Ho, Acta Mater. 55, 2805–2814 (2007).

K.N. Tu, Mater. Chem. Phys. 46, 217–223 (1996).

K.N. Tu and R.D. Thompson, Acta Metall. 30, 947–952 (1982).

H.L.J. Pang, K.H. Tan, X.Q. Shi, and Z.P. Wang, Mater. Sci. Eng. A 307, 42–50 (2001).

P.J. Shang, Z.Q. Liu, X.Y. Pang, D.X. Li, and J.K. Shang, Acta Mater. 57, 4697–4706 (2009).

Acknowledgements

The authors acknowledge William Heeschen and Charlie Wood for discussion of image analysis and FIB–SEM microscopy, respectively. We also thank the Advanced Packaging Technologies Metallization R&D teams for sample preparation and valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Jui-Ching Lin and Yi Qin contributed equally to this work.

Rights and permissions

About this article

Cite this article

Lin, JC., Qin, Y. & Woertink, J. Investigation of the Growth of Intermetallic Compounds Between Cu Pillars and Solder Caps. J. Electron. Mater. 43, 4134–4145 (2014). https://doi.org/10.1007/s11664-014-3318-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-014-3318-8