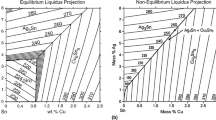

The majority of research on Pb-free solders has been done with reflow times sufficient to allow significant intermetallic growth at the liquid solder/pad interface. With the need for small, fine-pitched solder joints and to avoid damage to heat-sensitive read/write sensors, the hard disk drive industry predominantly uses solder jet bonding for electrical connections of the heads. This technique does not use flux and has solidification times on the order of a millisecond, four orders of magnitude smaller than that of conventional solder technology. Therefore, the intermetallic formation is highly nonequilibrium and is localized near the pad interface. Surface finish thicknesses and composition have a significant influence on intermetallic growth and composition of solder joints. The intermetallic microstructure, along with voids, can significantly impact joint reliability. In this paper, results of wettability and mechanical solder ball shear measurements on as-plated and aged samples are reported and correlated with microstructure and growth of intermetallic compounds (IMCs) at the solder/pad interface. A wide range of Au-Sn IMCs are found at the pad interface, and Au-embrittlement effects are not found until Au exceeds 7 wt.%.

Similar content being viewed by others

References

T. Oppert, L. Titerle, E. Zakel, G. Azdasht, and T. Teutscht, Proc. 35th Int. Symp. Microelectr. (2002), p. 145.

Y. Chen, Y. Tian, and C. Wang, Proc. 6th Inter. Con. Electron. Pack. Tech. (2005), p. 1.

A.T. Valota, A. Losavio, L. Renard, and A. Vicenzo, Therm., Mech. and MultiPhys. Simul. and Exp. in Microelect. and Micro-Systems (2006), p. 1.

F. Song, S.W. Lee, K. Newman, B. Sykes, and S. Clark, Proc. 57th Electron. Pack. Tech. Conf. (2007), p. 1504.

T.C. Chiu, K. Zeng, R. Stierman, D. Edwards, and K. Ano, Proc. 54th Electron. Pack. Tech. Conf. (2004), p. 1256.

S.C. Hung, P.J. Zheng, S.C. Lee, and J.J. Lee, Proc. 24th Electron. Manuf. Technol. Symp. (1999), p. 7.

C.E. Ho, R. Zheng, G.L. Luo, A.H. Lin, and C.R. Kao, J.␣Electron. Mater. 29, 1175 (2000).

M.H. Bester, Proc. Inter. NECON (1969), p. 211.

W.B. Harding and H.B. Pressly, Proc. 50th Ann. Conf. Am. Electropl. Soc. (1963), p. 90.

R.N. Wild, IBM Federal Systems Div., Owego, Rep. No. 07-825-2157 (1968).

D.M. Jacobson and G. Hampston, Gold Bull. 23, 79 (1989).

L.C. Shiau, C.E. Ho, and C.R. Kao, Solder. Surf. Mt. Tech. 14, 25 (2002).

J.L. Wagner, G. Houk, P.F. Ladwig, and D.P. Riemer, Whitepaper (Hutch. Technol. Inc., 2008).

JEDEC Standard JESEC-B117 (2000).

M.R. Pinnel and J.E. Bennet, Metal. Trans. 3, 1989 (1972).

H.G. Tompkins and M.R. Pinnel, J. Appl. Phys. 47, 3804 (1976).

Database for Properties of Lead-free Solder Alloys, ELFNET (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wagner, J.L., Ladwig, P.F., Riemer, D.P. et al. Microstructure, Intermetallic Growth, and Reliability of Rapidly Solidified Pb-Free Solder Joints Formed via Solder Ball Jetting. J. Electron. Mater. 38, 2600–2609 (2009). https://doi.org/10.1007/s11664-009-0881-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-009-0881-5