Abstract

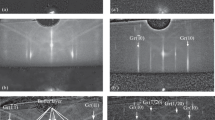

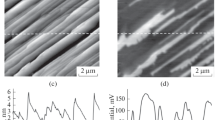

The formation of epitaxial graphene on SiC(0001) surfaces is studied using atomic force microscopy, Auger electron spectroscopy, electron diffraction, Raman spectroscopy, and electrical measurements. Starting from hydrogen-annealed surfaces, graphene formation by vacuum annealing is observed to begin at about 1150°C, with the overall step-terrace arrangement of the surface being preserved but with significant roughness (pit formation) on the terraces. At higher temperatures near 1250°C, the step morphology changes, with the terraces becoming more compact. At 1350°C and above, the surface morphology changes into relatively large flat terraces separated by step bunches. Features believed to arise from grain boundaries in the graphene are resolved on the terraces, as are fainter features attributed to atoms at the buried graphene/SiC interface.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

K.S. Novoselov, A.K. Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos, I.V. Grigorieva, and A.A. Firsov. Science 306, 666 (2004) doi:10.1126/science.1102896

W.A. de Heer, C. Berger, X. Wu, P.N. First, E.H. Conrad, X. Li, T. Li, M. Sprinkle, J. Hass, M.L. Sadowski, M. Potemski, and G. Martinez. Solid State Commun. 143, 92 (2007) doi:10.1016/j.ssc.2007.04.023

J. Kedzierski, P.-L. Hsu, P. Healey, P. Wyatt, C.L. Keast, M. Sprinkle, C. Berger, and W.A. de Heer. IEEE Trans. Electron. Dev. 55, 2078 (2008) doi:10.1109/TED.2008.926593

Y.Q. Wu, P.D. Ye, M.A. Capano, Y. Xuan, Y. Sui, M. Qi, J.A. Cooper, T. Shen, D. Pandey, G. Prakash, and R. Reifenberger. Appl. Phys. Lett. 92, 092102 (2008) doi:10.1063/1.2889959

G. Gu, S. Nie, R.M. Feenstra, R.P. Devaty, W.J. Choyke, W.K. Chan, and M.G. Kane. Appl. Phys. Lett. 90, 253507 (2007) doi:10.1063/1.2749839

J.A. Northrup, J. Neugebauer, Phys. Rev. B 57, 4230 (1998) doi:10.1103/PhysRevB.57.R4230

S. Mroczkowski, D. Lichtman. Surf. Sci. 131, 159 (1983) doi:10.1016/0039–6028(83)90125-5

P. Mårtensson, F. Owman, and L.I. Johansson, Phys. Status Solidi 202, 501 (1997). doi:10.1002/1521-3951(199707)202:1<501::AID-PSSB501>3.0.CO;2-H

W. Chen, H. Xu, L. Liu, X. Gao, D. Qi, G. Peng, S.C. Tan, Y. Feng, K.P. Loh, and A.T.S. Wee. Surf. Sci. 596, 176 (2005)

J.B. Hannon, R.M. Tromp. Phys. Rev. B 77, 241404 (2008) doi:10.1103/PhysRevB.77.241404

11. V. Ramachandran, M.F. Brady, A.R. Smith, R.M. Feenstra, and D.W. Greve. J. Electron. Mater. 27, 308 (1997) doi:10.1007/s11664-998-0406-7

Although the morphology of Fig. 3a is quite similar to that seen in Ref. 5, the annealing temperature reported there is higher (1300°C) and graphene thickness greater (1.5 ML) than the present work. It should be noted however that the starting surface in Ref. 5 is different, since the sample was transferred through air between H-etching and graphitization and also a small amount of surface metal contamination was present. Additionally, some uncertainty in temperature determination occurs in both experiments.

I. Forbeaux, J.-M. Themlin, J.-M. Debever. Phys. Rev. B 58, 16396 (1998) doi:10.1103/PhysRevB.58.16396

C. Riedl, U. Starke, J. Bernhardt, M. Franke, K. Heinz. Phys. Rev. B 76, 245406 (2007) doi:10.1103/PhysRevB.76.245406

15. T.A. Witten, L.M. Sander. Phys. Rev. Lett. 47, 1400 (1981) doi:10.1103/PhysRevLett.47.1400

16. S.W. Poon, W. Chen, E.S. Tok, A.T.S. Wee. Appl. Phys. Lett. 92, 104102 (2008) doi:10.1063/1.2883941

S. Nie (Ph.D. Thesis, Department of Physics, Carnegie Mellon University, 2007).

A.C. Ferrari, J.C. Meyer, V. Scardaci, C. Casiraghi, M. Lazzeri, F. Mauri, S. Piscanec, D. Jiang, K.S. Novoselov, S. Roth, and A.K. Geim. Phys. Rev. Lett. 97, 187401 (2006) doi:10.1103/PhysRevLett.97.187401

Z.H. Ni, W. Chen, X.F. Fan, J.L. Kuo, T. Yu, A.T.S. Wee, and Z.X. Shen. Rev. B 77, 115416 (2008) doi:10.1103/PhysRevB.77.115416

J.C. Burton, L. Sun, F.H. Long, Z.C. Feng, I.T. Ferguson. Phys. Rev. B 59, 7282 (1999) doi:10.1103/PhysRevB.59.7282

D. Graf, F. Molitor, K. Ensslin, C. Stampfer, A. Jungen, C. Hierold, , and D. Wirtz. Nano Lett. 7, 238 (2007) doi:10.1021/nl061702a

G.M. Rutter, N.P. Guisinger, J.N. Crain, E.A.A. Jarvis, M.D. Stiles, T. Li, P.N. First, and J.A. Stroscio. Phys. Rev. B 76, 235416 (2007) doi:10.1103/PhysRevB.76.235416

S. Nie and R.M. Feenstra, J. Vac. Sci. Technol. B, submitted

Acknowledgements

The authors are grateful to W.J. Choyke, R.P. Devaty, W. Hu, K. Oman, N. Srivastava, and Y. Yin for useful discussions and for technical assistance. This work was supported by the National Science Foundation (Grant DMR-0503 748), and by the Defense Advanced Research Projects Agency through a contract administered by the Air Force Research Laboratory (Contract FA8650-08-C-7823). The work is approved by DARPA for public release, distribution unlimited. Use of the Center for Nanoscale Materials at Argonne National Laboratory was supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. Opinions are those of the authors and are not necessarily endorsed by the funding sources.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License ( https://creativecommons.org/licenses/by-nc/2.0 ), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Luxmi, Nie, S., Fisher, P. et al. Temperature Dependence of Epitaxial Graphene Formation on SiC(0001). J. Electron. Mater. 38, 718–724 (2009). https://doi.org/10.1007/s11664-008-0584-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-008-0584-3