Abstract

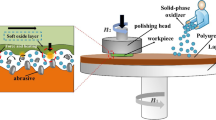

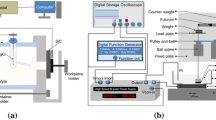

In this study we investigated the possibility of removing and flattening a single-crystal silicon carbide (SiC) surface by a novel polishing method utilizing hydroxyl radicals (OH radicals) generated on an Fe catalyst surface. To demonstrate the feasibility of preparing a smooth SiC surface, an Fe catalyst and a SiC substrate were rubbed together in H2O2 solution, and then the area on the SiC surface that had come into contact with the Fe catalyst was observed in detail. The removal depth and surface microroughness were measured and evaluated using a phase-shift interference microscope and an atomic force microscope (AFM), respectively. Moreover, the removal of material from the SiC surface by utilizing an Fe catalyst rod was examined. The obtained results show that the hard SiC surface can be effectively polished and that the processed area on the SiC surface has atomic-level smoothness along the sliding direction. Moreover, it is shown that the removal characteristics of the SiC substrate depend on process parameters such as the process time, rotation speed, contact load, and concentration of H2O2 solution. These results provide useful information for preparing an atomically smooth SiC surface.

Similar content being viewed by others

References

L. Zhou, V. Audurier, P. Pirouz, J.A. Powell. J. Electrochem. Soc. 144, L161 (1997) doi:10.1149/1.1837711

F. Owman, C. Hallin, P. Martensson, E. Janzen, J. Cryst. Growth 167, 391 (1996) doi:10.1016/0022-0248(96)00296-5

V. Ramacandran, M.F. Brady, A.R. Simth, R.M. Feenstra, and D.W. Greve J. Electron. Mater. 27, 308 (1998) doi:10.1007/s11664-998-0406-7

B. Kim, H.J. Choi, B.T. Lee, J. Vac. Sci. Technol. A 20, 424 (2002) doi:10.1116/1.1448509

H. Hara, Y. Sano, H. Mimura, K. Arima, A. Kubota, K. Yagi, K. Yamauchi, J. Electron. Mater. 35, L11 (2006) doi:10.1007/s11664-006-0218-6

H. Hara, Y. Sano, K. Arima, K. Yagi, J. Murata, A. Kubota, H. Mimura, K. Yamauchi, Sci. Technol. Adv. Mater. 8, 162 (2007) doi:10.1016/j.stam.2006.12.004

Y. Ishikawa, Y. Matsumoto, Y. Nishida, S. Taniguchi, J. Watanabe, J. Am. Chem. Soc. 125, 6558 (2003) doi:10.1021/ja020359i

Y. Sano, M. Watanabe, K. Yamamura, K. Yamauchi, T. Ishida, K. Arima, A. Kubota, Y. Mori, Jpn. J. Appl. Phys. 45, 8277 (2006) doi:10.1143/JJAP.45.8277

Acknowledgements

This research was supported by a Grant-in-Aid for Young Scientists (B) (No. 18760102) from the Ministry of Education, Culture, Sports, Science, and Technology. This work was also supported in part by Grants from the Nakajima Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kubota, A., Yagi, K., Murata, J. et al. A Study on a Surface Preparation Method for Single-Crystal SiC Using an Fe Catalyst. J. Electron. Mater. 38, 159–163 (2009). https://doi.org/10.1007/s11664-008-0583-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-008-0583-4