Abstract

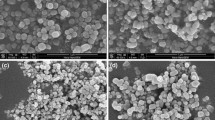

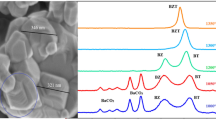

Nanometric-sized barium titanate powders were prepared by using titanium isopropoxid as the raw material and acetylacetone as a chelating agent, in a strong alkaline solution (pH > 13) through the sol-precipitation method. The preparatory variables affect the extent of cross-linking in the structure, change the mode of condensation of the gels, and even control the particle size of the powder. The reaction rate of forming powder, at a higher temperature such as 100°C and more water content (the molar ratio of water to titanium isopropoxide is 25) or fewer acetylacetone (the molar ratio of acetylacetone to titanium isopropoxide is 1), is rapid and the particle size formed is finer at 60–80 nm. On the contrary, that of forming powder, at lower temperature (40°C) and less water content (molar ratio of water/titanium isopropoxide = 5) or higher acetylacetone (acetylacetone/titanium isopropoxide = 7), is slow and the particle size of the powder is larger. The optimal preparatory conditions were obtained by using the experimental statistical method; as a result, nanometric-sized BaTiO3 powder with an average particle size of about 50 nm was prepared.

Similar content being viewed by others

References

N.H. Chen, R.K. Sharma, D.M. Smyth J. Electrochem. Soc.: Solid-State Sci. Technol. 128, 1762 (1981)

A. Mackor, G. Blasse Chem. Phys. Lett. 77, 6 (1981)

M.P. Pechini U.S. Patent 3 330,697 (1967)

B.A. Tuttle, Ceramic Powder, ed. P. Vincenzini (Amsterdam: Elsevier, 1987), pp. 62–69

D.E. Rase, R. Roy J. Chem. Phys. 19, 33 (1951)

D.Y. Wang, K. Umeya J. Am. Ceram. Soc. 73, 669 (1990)

K. Uchino, Mater. Sci. Forum 62, 251 (1990)

S. Chatterjee, K. Sengupta, H.S. Maiti, Sens. Actuat. B60, 155 (1999)

J.M. Wilson, J.W. Symes U.S. Patent 5 783,165 (1998)

P.R. Arya, P. Jha, G.N. Subbanna, A.K. Ganguli Mater. Res. Bull 38, 617 (2003)

H.B. Sharma, H.N.K. Sarma Thin Solid Films 330, 178 (1998)

M.Z.C. Hu, V. Kurian E.A. Payzant C.J. Rawn, R.D. Hunt Powder Technol. 110, 2 (2000)

J.Q. Qi, Y. Wang, W.P. Chen, L.T. Li, H.L.W. Chan J. Solid State Chem. 178, 279 (2005).

S. Urek, Drofenik J. Euro. Ceram. Soc 18, 279 (1998)

K.M. Hung, W.D. Yang, C.C. Huang J. Euro. Ceram. Soc. 23, 1901 (2003)

F. Guangneng, H. Lixia, H. Xueguang J. Cryst. Growth 279, 489 (2005)

R.W. Schwartz, J.A. Voigt, B.A. Tuttle, D.A. Payne, T.L. Reichert, R.S. Dasalla J. Mater. Res 12, 444 (1997)

C.S. Hsieh, T.S. Liou Quality Eng. 13, 449 (2001)

C.F. Kao, W.D. Yang Ceram. Int. 22, 57 (1996)

L. Weng, X. Bao, K.S. Crentsil Mater. Sci. Eng. B96, 307 (2002)

S.S. Flaschen J. Am. Chem. Soc. 77, 6194 (1955)

Acknowlegement

The authors thank the National Science Council (Grant No. NSC 91-2218-E-151-002) for financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hung, K.M., Hsieh, C.S., Yang, W.D. et al. Synthesis of Nanometric-Sized Barium Titanate Powders Using Acetylacetone as the Chelating Agent in a Sol-Precipitation Process. J. Electron. Mater. 36, 245–252 (2007). https://doi.org/10.1007/s11664-006-0027-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-006-0027-y