Abstract

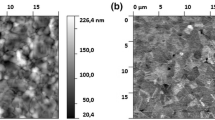

In order to achieve copper wafer bonding with good quality, surface conditions of copper films are important factors. In this work, the effects of surface conditions, such as surface roughness and oxide formation on the bond strength, were investigated under different bonding conditions. Prior to bonding, copper film surfaces were kept in the atmosphere for less than 1 min, 3 days, and 7 days, respectively, to form different thicknesses of oxide on the surface. Some copper wafers were cleaned using HCl before bonding in order to remove the surface oxide. Surface roughness of copper films with and without HCl cleaning was examined. Since surface cleaning before bonding removes oxides but creates surface roughness, it is important to study the corresponding bond strength under different bonding conditions. These results offer the required information for the process design of copper wafer bonding in three-dimensional integration applications.

Similar content being viewed by others

References

Y. Akasaka and T. Nishimure, IEDM Tech. Dig., p. 488 (1986).

T. Kunio, K. Oyama, Y. Hayashi, and M. Morimoto, IEDM Tech. Dig., p. 837 (1989).

K. Yamazaki, Y. Itoh, A. Wada, K. Morimoto, and Y. Tomita, IEDM Tech. Dig., p. 161 (2000).

J.A. Davis, R. Venkatesan, A. Kaloyeros, M. Bylansky, S.J. Souri, K. Banerjee, K.C. Saraswat, A. Rahman, R. Reif, and J.D. Meindl, Proc. IEEE 89, 305 (2001).

Kuan-Neng Chen, Mauro Kobrinsky, Brandon Barnett, and Rafael Reif, Trans. Electron Dev. 51, 233 (2004).

K. Banerjee, S.J. Souri, P. Kapur, and K.C. Saraswat, Proc. IEEE 89, 602 (2001).

J. D. Meindl, R. Venkatesan, J.A. Davis, J. Joyner, A. Naeemi, P. Zarkesh, M. Bakir, T. Mule, P.A. Kohl, and K.P. Martin, IEDM Tech. Dig., p. 525 (2001).

A. Rahman, A. Fan, and R. Reif, Proc. 2000 IEEE Int. Interconnect Conf. (Piscataway, NJ: IEEE, 2000), pp. 157–159.

K.W. Lee, T. Nakamura, T. Ono, Y. Yamada, T. Mizukusa, H. Hashimoto, K.T. Park, H. Kurino, and M. Koyanagi, IEDM Tech. Dig., p. 165 (2000).

A. Fan, K.N. Chen, and R. Reif, Proc. Electrochemical Society Spring Meeting (ULSI Process Integration Symposium, 2001–2002), (Washington, DC: The Electrochemical Society), p. 124.

R.W. Bower, M.S. Ismail, and S.N. Farrens, J. Electron. Mater. 20, 383 (1991).

Kuan-Neng Chen, Andy Fan, and Rafael Reif, J. Electron. Mater. 30, 331 (2001).

K.N. Chen, A. Fan, C.S. Tan, and R. Reif, Appl. Phys. Lett. 81, 3774 (2002).

K.N. Chen, A. Fan, C.S. Tan, and R. Reif, J. Electron. Mater. 32, 1371 (2003).

K.N. Chen, C.S. Tan, A. Fan, and R. Reif, Electrochem. Solid-State Lett. 7, G14 (2004).

K. Holloway, P.M. Fryer, C. Cabral, Jr., J.M.E. Harper, P.J. Bailey, and K.H. Kellenher, J. Appl. Phys. 71, 5433 (1992).

S.R. Radel and M.H. Navidi, Chemistry, 2nd ed. (West Publishing Company, 2001), pp. 476–477.

K.N. Chen, A. Fan, and R. Reif, J. Mater. Sci. 37, 3441 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, K.N., Tan, C.S., Fan, A. et al. Copper bonded layers analysis and effects of copper surface conditions on bonding quality for three-dimensional integration. J. Electron. Mater. 34, 1464–1467 (2005). https://doi.org/10.1007/s11664-005-0151-0

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-005-0151-0