Abstract

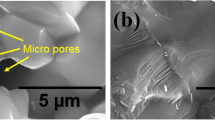

We report on the investigation of ohmic contact formation using sputtered titanium-tungsten contacts on an inductively coupled plasma (ICP) etch-damaged 4H-SiC surface. Transfer length method (TLM) measurements were performed to characterize how ICP-etch damage affects the performance of ohmic contacts to silicon carbide. In order to recover etch damage, high-temperature oxidation (1250°C for 1 h) was evaluated for one of the samples. Some of the etch damage was recovered, but it did not fully recover the etch damage for the sample etched with medium platen power (60 W). From our TLM measurements, the specific contact resistance (ρ C of sputtered titanium tungsten on highly doped n+-type 4H-SiC epilayers with a doping of 1.1×1019 cm−3 for the unetched reference sample, 30-W etched, and 60-W etched with and without sacrificial oxidation was as low as 3.8×10−5 Ωcm2, 3.3×10−5 Ωcm2, 2.3×10−4 Ωcm2, and 1.3×10−3 Ωcm2, respectively. We found that the low-power (30 W) ICP-etching process did not affect the formation of ohmic contacts, and we did not observe any difference between the unetched and the 30-W etched sample from our TLM measurements, having the same value of the ρ C. However, medium-platen-power (60 W) ICP etching showed significant influence on the ohmic contact formation. We found that the specific contact resistance is highly related to the surface roughness and quality of the metals, and the lower, specific contact resistance is due to smoother and denser ohmic contacts.

Similar content being viewed by others

References

R.J. Trew, Phys. Status Solidi A162, 409 (1997).

A.A. Yassen, C.A. Zorman, and M. Mehregany, J. Microelectromech. Sys. 8, 237 (1999).

W.S. Pan and A.J. Stekl, J. Electrochem. Soc. 137, 212 (1990).

J.R. Flemish, K. Xie, and G.F. McLane, Mater. Res. Soc. Symp. Proc. 421, 153 (1996).

J.J. Wang, E.S. Lambers, S.J. Pearton, M. Östling, C.-M. Zetterling, J.M. Grow, F. Ren, and R.J. Shul, J. Vac. Sci. Technol. A16, 2204 (1998).

F.A. Khan and I. Adesida, Appl. Phys. Lett. 75, 2268 (1999).

E. Danielson, C.-M. Zetterling, M. Östling, S.-K. Lee, K. Linthicum, D.B. Thomson, O.H. Nam, and R.F. Davis, Mater. Sci. Forum. 338–342, 1049 (2000).

E. Danielson, S.-K. Lee, C.-M. Zetterling, and M. Östling, J. Electron. Mater. 30, 247 (2001).

P. Leerungnawarat, K.P. Lee, S.J. Pearton, F. Ren, and S.N. Chu, J. Electron. Mater. 30, 202 (2001).

F.A. Khan, B. Roof, L. Zhou, and I. Adesida, J. Electron. Mater. 30, 212 (2001).

S.M. Sze, Physics of Semiconductor Devices, 2nd ed. (New York: John Wiley & Sons. Inc., 1981), pp. 245–46.

L.M. Porter and R.F. Davis, Mater. Sci. Eng. B34, 83 (1995).

V. Hoffman, Solid State Technol. 26, 119 (1983).

C.M. Winter and P. Pizzo, IEEE Int. Electron Manufacturing Technology Symp. Proc. (Baltimore, MD: IEEE, 1992), p. 124.

J. Crofton, J.R. Williams, M.J. Bozack, and P.A. Barnes, Inst. Phys. Conf. Ser. 137, 719 (1994).

S.-K. Lee, C.-M. Zetterling, and M. Östling, Mater. Res. Soc. Symp. Proc. 640, H7.2 (2000).

S.-K. Lee, C.-M. Zetterling, and M. Östling, J. Appl. Phys. 87, 8039 (2000).

A. Elshabini and F.D. Barlow, Thin Film Technology Handbook (New York: McGraw-Hill, 1997), pp. 42–44.

CREE Research Inc., Durham, NC.

V. Khemka, T.P. Chow, and R.J. Gutman, J. Electron. Mater. 27, 1128 (1998).

S.N. Ganguli and D. Berk, J. Vac. Sci. Technol. A6, 3068 (1988).

W. Schockley, Rep. No. AFAL-TDR-64-207 (1963).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, S.K., Koo, S.M., Zetterling, C.M. et al. Ohmic contact formation on inductively coupled plasma etched 4H-silicon carbide. J. Electron. Mater. 31, 340–345 (2002). https://doi.org/10.1007/s11664-002-0079-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-002-0079-6