Abstract

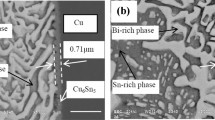

The growth mechanism of intermetallics between solders and metallized substrates, after thermal aging, are investigated. The solders used in this study are unleaded Sn-Cu-Ni solder and eutectic Pb-Sn solder. The Pt-Ag/Al2O3, Cu block and the electroless Cu/Pt-Ag/Al2O3 are employed as the metallized substrates. Microstructure evolution of the interfacial morphology, elemental, and phase distribution are probed with the aid of electron-probe microanalyzer (EPMA) and x-ray diffractometry. Two kinds of intermetallics, Cu3Sn and Cu6Sn5, are formed at the solder/Cu interface. However, for the solder/Pt-Ag system, only Ag3Sn is observed at the interface. The thickness of Cu3Sn, Cu6Sn5, and Ag3Sn compound layers for all solder/metallized substrate systems shows at t0.5 dependence at 100, 125, 150 and 170 C. According to the calculated activation energy and diffusion constant, the growth rate of Cu3Sn and Cu6Sn5 intermetallics in the electroless Cumetallized substrate is relatively higher than that for Cu block one at the range of 100 C to 170 C. However, the growth rate of Cu6Sn5 and Ag3Sn is reduced in the Sn-Cu-Ni solder with respect to the eutectic Pb-Sn solder. On the other hand, the Sn-Cu-Ni solder system exhibits a thicker Cu3Sn intermetallic layer than the eutectic Pb-Sn solder after various aging times at 100 C. The thickness of Cu3Sn in the eutectic Pb-Sn solder is, however, thicker than that for Sn-Cu-Ni solder at 170 C.

Similar content being viewed by others

References

D. R. Frear and F. G. Yost, MRS Bulletin 18, 49 (1993).

J. K. Hagge and G. J. Davis, Circuit World 11, 8 (1985).

J. K. Hagge, Specification 489-0012-001B, Rockwell-Collins Working Paper WP 83-2020 (July 1983).

P. E. Davis, M. E. Warwick, and P. J. Kay, Plating and Surface Finishing 69, 72 (1982).

K. Banerji and R. F. Darveaux, First Int. Conf. on Microstructures and Mechanical Properties of Aging Materials (Warrendale, PA: The Minerals, Metals & Materials Society, 1992–1993), p. 431.

J. H. Lau, Thermal Stress and Strain in Microelectronic Packaging (New York: Van Nostrand Reinhold, 1993).

R. Satoh, Thermal Stress and Strain in Microelectronic Packaging, ed. J. H. Lau (New York: Van Nostrand Reinhold, 1993).

H. D. Solomon, IEEE Trans. Comp. Hybrids. Manuf. Technol. CHMT-9, 423 (1986).

P. Viswanadham and J. Colangelo, Surface Mount Technol. 13, 64 (1998).

M. E. Loomans, S. Vaynman, G. Ghosh, and M. E. Fine, J. Electron. Mater. 23, 741 (1994).

I. Artaki and A. M. Jackson, J. Electron. Mater. 23, 757 (1994).

Z. Mei and J. W. Morris, Jr., J. Electron. Mater. 21, 599 (1992).

M. McCormack and S. Jin, J. Electron. Mater. 23, 635 (1994).

M. McCormack and S. Jin, J. Electron. Mater. 23, 715 (1994).

A. Grusd, Proc of the NEPCON WEST’99 (Norwalk, CT: Reed Exhibition Companies, 1999), p. 212.

P. G. Harris and K. S. Chaggar, Soldering & Surface Mount Technol. 30, 38 (1998).

T. M. Korhonen, S. J. Hong, M. A. Korhonen, and C. Y. Li, Proc. Electron. Pkg. Mater. Sci. 515, 79 (1998).

Y. Wu, J. A. Sees, C. Pouraghabagher, L. A. Foster, J. L. Marshall, E. G. Jacobs, and R. F. Pinizzotto, J. Electron. Mater. 22, 769 (1993).

W. Yang, R. W. Messier, Jr., and E. F. Lawrence, J. Electron. Mater. 23, 765 (1994).

P. Vianco, P. F. Hlava, and A. C. Kilgo, J. Electron. Mater. 23, 583 (1994).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Young, C.C., Duh, J.G. & Tsai, S.Y. Microstructural evolution in the Sn-Cu-Ni and Pb-Sn solder joints with Cu and Pt-Ag metallized Al2O3 substrate. J. Electron. Mater. 30, 1241–1248 (2001). https://doi.org/10.1007/s11664-001-0156-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11664-001-0156-2