Abstract

Differences in the coefficients of thermal expansion (CTE) between silicon wafers and underlying copper electrodes have led to the use of purely mechanical dry pressure contacts for primary electrical and thermal connections in high-power solid-state electronic devices. These contacts are limited by their ability to dissipate I2R heat from within the device and by their thermal fatigue life. To increase heat dissipation and effectively deal with the CTE mismatch, metallurgical bonding of the silicon to a specially-structured, strain-accommodating copper electrode has been proposed. This study was intended to seek alternative methods for and demonstrate the feasibility of bonding Si to structured Cu in high-power solid-state devices. Three different but fundamentally related fluxless approaches identified and preliminarily assessed were: (1) conventional Sn−Ag eutectic solder; (2) a new, commercially-available active solder based on the Sn−Ag eutectic; and (3) solid-liquid interdiffusion bonding using the Au−In system. Metallurgical joints were made with varying quality levels (according to nonde-structive ultrasonic C-scan mapping, SEM, and electron microprobe) using each approach. Mechanical shear testing resulted in cohesive failure within the Si or the filler alloys. The best approach, in which eutectic Sn−Ag solder in pre-alloyed foil form was employed on Si and Cu substrates metallized (from the substrate outward) with Ti, Ni and Au, exhibited joint thermal conduction 74% better than dry pressure contacts.

Similar content being viewed by others

References

S.K. Ghandhi, Semiconductor Power Devices (New York: John Wiley and Sons, 1977), pp. 265–308.

K. Heumann, Basic Principles of Power Electronics (Berlin: Springer-Verlag, 1986), pp. 13–15.

D.R. Lide, editor, CRC Handbook of Chemistry and Physics, 78th edition (Boca Raton, FL: CRC, 1997), pp. 12–191.

W. Yang, and R.W. Messler, Jr., J. Electron. Mater., 23, 765 (1994).

W. Yang, L.E. Felton, and R.W. Messler, Jr., J. Electron. Mater. 24, 1465 (1995).

J.F. Shackelford, Introduction to Materials Science for Engineers, 3rd edition (New York: Macmillan Publ. Co., 1985), p. 406.

R.W. Smith, Paper presented at the 29th AWS International Brazing and Soldering Conf. (Detroit, MI, 29 April 1998).

R.W. Smith, Mater. Resources Int. (1998).

L. Berstein, J. Electrochem. Soc. 113, 1282 (1966).

C.C. Le, C.Y. Wang, and G. Matijasevic, IEEE Trans. on Component, Hybrids and Mfg. Technol. 6, 311 (1993).

H.H. Manko, Solders and Soldering Materials: Design, Production and Analysis for Reliable Bonding, 3rd edition (New York: McGraw-Hill 1992), pp. 116–117.

S.P. Murarka, Metallizations: Theory and Practice for VLSI and ULSI (Stoneham, MA: Butterworth-Heinemann, 1993), p. 73.

P.T. Vramis, Soldering Manual, 3rd edition (Miami, FL: Amer. Welding Soc., 1999), p. 80.

K. Mizuishi, and T. Mori, IEEE Trans. of Component, Hybrids, and Mfg. Technol. 11, 481 (1988).

J.W. Bulter, H. Glascock, and R.F. Dyer, J. Energy 6, 240 (1982).

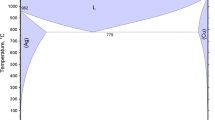

T.B. Massalski, editor-in-chief, Binary Alloy Phase Diagrams, 2nd edition (Materials Park, OH: ASM Int., 1990).

L.E. Felton (Ph.D. thesis, Rensselaer Polytechnic Institute. Troy, NY, May 1991).

G. Humpston and D.M. Jacobson, Principles of Soldering and Brazing (Materials Park, OH: ASM Int., 1993), p. 9.

Author information

Authors and Affiliations

Additional information

Formally an M.S. candidate at Rensselaer Polytechnic Institute, Troy, NY.

Professor of Materials Science and Engineering/Director of Materials Joining, advised Mr. Faust

sponsor of the development effort

Rights and permissions

About this article

Cite this article

Faust, N., Messler, R.W. & Khatri, S. Alternatives for joining Si wafers to strain-accommodating Cu for high-power electronics. J. Electron. Mater. 30, 1276–1286 (2001). https://doi.org/10.1007/s11664-001-0112-1

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11664-001-0112-1