Abstract

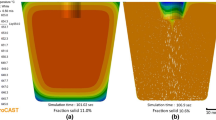

During centrifugal casting of copper alloys containing graphite particles, both particles and bubbles move under the influence of centrifugal forces and influence the final microstructure, including porosity and the distribution of graphite. The movement of graphite particles and bubbles in the melts of copper alloys, originally containing 7 and 13 vol pct graphite particles and centrifugally cast at 800 and 1900 rpm in horizontal rotating molds, has been examined. Microstructural observations of sections of these centrifugal castings show that the graphite particles are segregated near the inner periphery and the amount of porosity in the graphite-rich zone is higher than the porosity in the graphite-free and transition zones. The intimate association of porosity with graphite particles in the graphite-rich zone was explained on the basis of attachment of graphite particles to bubbles in the melt and the viscosity of the melt, which increases with increasing concentration of graphite particles near the inner periphery of the castings. It was found that the amount of the porosity in the graphite-rich zone increases with volume fraction of graphite particles used in this study; the size of the porosity in the graphite-rich zone also increases with increasing rotational speed of the mold. This suggests that the graphite particles and bubbles were attached to each other in the melt and they did not get separated during centrifugal casting conditions of the present study. The present experiments qualitatively confirm theoretical computations.

Similar content being viewed by others

References

P.K. Rohatgi, S. Ray, D. Nath, N. Church, and D. Peters: AFS Trans., 1992, vol. 100, pp. 1–9.

P.K. Rohatgi, D. Nath, and S. Ray: AFS Trans., 1993, vol. 101, pp. 42–58.

A. Saigal and P.K. Rohatgi: AFS Trans., 1996, vol. 104, pp. 225–28.

P.K. Rohatgi, J.K. Kim, J. Sobczak, and S. Ray: AFS Trans., 1996, vol. 104, pp. 1217–22.

P.K. Rohatgi, J.K. Kim, J. Sobczak, and N. Sobczak: Processing and Properties of Cast Metal Matrix Composites, TMS Materials Week, Cincinnati, OH, 1996, P.K. Rohatgi, ed., TMS, Warrendale, PA, 1996, pp. 271–88.

P.K. Rohatgi, R. Asthana, and S. Das: Int. Met. Rev., 1986, vol. 31 (3) pp. 115–39.

A. Mortensen and I. Jin: Int. Met. Rev., 1992, vol. 3 (3), pp. 101–28.

P.K. Ghosh and S. Ray: AFS Trans., 1988, vol. 96, pp. 775–82.

G.S. Hanumanth, G.A. Irons: J. Mater. Sci., 1993, vol. 28, pp. 2459–65.

J.K. Kim and P.K. Rohatgi: Metall. Mater. Trans. B, 1999, vol. 308, pp. 0000–00.

J. Szekely: Fluid Flow Phenomena in Metal Processing, Academic Press, New York, NY, 1979, pp. 250–55.

E.M. Klier, A. Mortensen, J.A. Cornie, and M.C. Flemings: J. Mater. Sci., 1991, vol. 26, pp. 2519–26.

W.R. Schowalter: Mechanics of Non-Newtonian Fluids Pergamon Press, Elmsford, NY, 1978, p. 288.

D. Shangguan and D.M. Stefanescu: Metall. Mater. Trans. B, 1991, vol. 22B, pp. 385–88.

J.A. Sekhar and R. Trivedi: in Solidification of Metal Matrix Composites, P.K. Rohatgi, ed., TMS, Warrendale, PA, 1990, pp. 39–50.

N. Setargew, B.A. Parkers, and M.J. Couper: Int. Conf. on Advanced Composite Material, Feb., 1993, Wollongong, Australia, TMS, Warrendale, PA, pp. 1021–27.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, J.K., Rohatgi, P.K. Effect of interactions between bubbles and graphite particles in copper alloy melts on microstructure formed during centrifugal casting: Part II. Experiments. Metall Mater Trans B 30, 369–373 (1999). https://doi.org/10.1007/s11663-999-0068-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-999-0068-8