Abstract

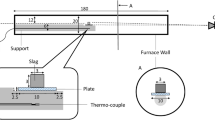

The alumina content in the iron ore imported to Japan is increasing year by year, and some problems in blast furnace operation, due to the use of the high-alumina-containing sinter, have already been reported. In order to clarify the mechanism of the harmful effect of alumina on the blast furnace operation, the behavior of the primary melt, which is formed in the sinter at the cohesive zone of the blast furnace, has been simulated by dripping slag through an iron or oxide funnel. The effects of basicity, Al2O3, and Fe t O contents in the five slag systems on the dripping temperature and weight of slag remaining on the funnel have been discussed. It was found that the eutectic melt formed in the sinter would play an important role in the dripping behavior of the slag in the blast furnace through the fine poreosity of the reduced iron and ore particles. Al2O3 increased the weight of the slag remaining on the funnel, and its effect became very significant in the acidic and low-Fe t O-containing slag. It was estimated that the increase of the weight of the slag remaining on the funnel by Al2O3 in the ore could result in a harmful effect on the permeability resistance and an indirect reduction rate of the sinter in the blast furnace.

Similar content being viewed by others

References

Y. Hida and Y. Nosaka: Tetsu-to-Hagane, 78 (1992), pp. 960–965.

Y. Nosaka and Y. Hosotani: Tetsu-to-Hagane, 75 (1989), pp. 1957–1962.

T. Kawaguchi, S. Kasama and T. Inazumi: Tetsu-to-Hagane, 78 (1992), pp. 1053–1060.

H. Ueno, K. Yamaguchi, T. Orimoto, Y. Okuno, S. Matsunaga, H. Oda, S. Amano and M. Nose: Proc. 1st Intern. Cong. on Sci. Tech. Ironmaking, The Iron Steel Inst. Jpn., Tokyo, Japan, 1994, pp. 217–222.

P.R. Dawson, J. Ostwald and K.M. Hayes: Proc. Symp. Sampling Analys. Miner. Industry, IMM, 1982, C71.

I. Shigaki, M. Sawada, M. Maekawa and K. Narita: Tetsu-to-Hagane, 66 (1980), pp. 1612–1621.

A. Muan and E.F. Osborn: Reprint of paper presented before General Meeting of Am. Iron Steel Inst., New York, NY, 1951.

J.F. Schairer: J. Am. Ceram. Soc., Vol. 25, 1942, pp. 256–265.

E.M. Levin, C.R. Robbins and H.F. McMurdie: Phase Diagrams for Ceramists, Vol. 1, The Am. Ceram. Soc., Columbus, OH, USA, 1964.

H. Ohgusu, Y. Sassa, Y. Tomita and K. Tanaka: Proc. 1st Int. Congr. on Sci. Tech. Ironmaking, The Iron Steel Inst. Jpn., Tokyo, Japan, 1994, pp. 229–234.

M. Hino, S. Yamamoto and S. Ban-ya: Tetsu-to-Hagane, Vol. 79, 1993, pp. 1039–1045.

F. Bashforth and J.C. Adams: An Attempt of Test the Theories of Capillary Action, Cambridge University Press, Cambridge, United Kingdom, 1883.

I. Jimbo and A.W. Cramb: Proc. 6th Int. Iron Steel Congr., The Iron Steel Inst. Jpn., Tokyo, 1990, pp. 499–504.

I. Jimbo and A.W. Cramb: Iron Steel Inst. Jpn. Int., 1992, vol. 32, pp. 26–35.

Y. Omori and E. Kasai: Proc. 6th Int. Iron Steel Congr., The Iron and Steel Institute of Japan, Tokyo, 1990, pp. 1–14.

P. Kozakevitch: Rev. Met., 1949, vol. 46, pp. 505–25 and pp. 572–83.

Y. Kawai, K. Mori, H. Shiraishi, and N. Yamada: Tetsu-to-Hagane, 1976, vol. 62, pp. 53–61.

Handbook of Physico-Chemical Properties at High Temperature, Y. Kawai and Y. Shiraishi, eds., The Iron and Steel Institute of Japan, Tokyo, 1988.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hino, M., Nagasaka, T., Katsumata, A. et al. Simulation of primary-slag melting behavior in the cohesive zone of a blast furnace, considering the effect of Al2O3, Fe t O, and basicity in the sinter ore. Metall Mater Trans B 30, 671–683 (1999). https://doi.org/10.1007/s11663-999-0028-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-999-0028-3