Abstract

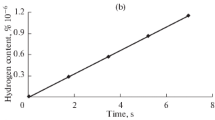

Chlorine fluxing is widely used in the aluminum industry for the removal of magnesium from molten aluminum. Typically, it consists of bubbling a nitrogen/chlorine or argon/chlorine mixture into the melt. This Part I of a two-part article describes laboratory-scale experiments on the kinetics of the reactions and emissions during chlorine fluxing for magnesium removal. Bubble frequency, size, and residence time were measured by a two-microphone detection system, which lead to an estimate of the melt-gas interfacial area. Emissions were found to be low, provided the melt temperature was above the melting point of magnesium chloride and provided the magnesium content was above a critical level. Experimental results suggested the chlorine supply to be the rate-determining factor above this critical level and magnesium mass transport to be the rate-determining factor below the critical level.

Similar content being viewed by others

References

The Aluminum Association, Washington, DC, Press release, March 26, 1996.

Thermodynamics Database, U.S. Bureau of Mines, Washington, DC, 1996, courtesy A.E. Morris.

D.V. Neff and B.P. Cochran: Light Met., 1993, pp. 1053–60.

EPA: Toxic Release Inventory, 1987–1994, CD-ROMs.

L.J. Derham: U.S. Patent 3,650,730, 1972.

D.V. Neff: AIME Recycle and Secondary Recovery of Metal, AIME, New York, NY, 1985, p. 73.

D.V. Neff: Light Matals, TMS, Warrendale, PA, 1987, p. 805.

J. Szekely and N. Themelis: Rate Phenomena in Process Metallurgy, Wiley-Interscience, New York, NY, 1971.

F.D. Richardson: Metall. Trans., 1971, vol. 2, pp. 2747–56.

B. Kulunk and R. Gutherie: Light Met., 1992, pp. 963–75.

R.J. Andreini, J.S. Foster, and R.W. Callen: Metall. Trans. B, 1977, vol. 8B, pp. 625–31.

G.K. Sigworth and T.A. Engh: Scand. J. Metall., 1982, vol. 11, pp. 143–49.

B. Lagowski: Trans. AFS, 1968, pp. 205–07.

J. Stevens and Ho Yu: Light Met., 1986, pp. 837–45.

Q. Fu: Master’s Thesis, University of California, Berkeley, CA, 1997.

ASTM Annual Book, ASTM, Philadelphia, PA, 1996, vol. 03.05, pp. 32–35.

M. Sano, K. Mori, and T. Sato: J. Iron Steel Inst. Jpn., 1977, vol. 63, p. 2308.

K. Tsuchiya, M. Aida, Y. Fujii, and M. Okamoto: J. Nucl. Mater., 1993, vol. 207, pp. 123–29.

J. Botor: Metall. Odelwnictwo, 1981, pp. 393–406.

M. Iguchi, H. Kawabata, K. Nakajima, and Z. Morita: Metall. Mater. Trans. B, 1995, vol. 26B, pp. 67–74.

R.B. Bird, W.E. Stewart, and E.N. Lightfoot: Transport Phenomena, John Wiley & Sons, New York, NY, 1960.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Fu, Q., Xu, D. & Evans, J.W. Chlorine fluxing for removal of magnesium from molten aluminum: Part I. Laboratory-scale measurements of reaction rates and bubble behavior. Metall Mater Trans B 29, 971–978 (1998). https://doi.org/10.1007/s11663-998-0065-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-998-0065-3