Abstract

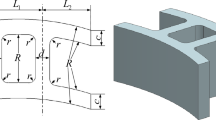

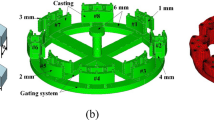

Investment casting technology has been increasingly applied in the aerospace field due to its advantages, but investment castings inevitably undergo shrinkage deformation due to the principles of casting. However, the allocation of shrinkage allowance coefficient is not reasonable. The casting sizes are severely deviating from tolerances and the mold needs to be repaired repeatedly. In addressing the problem, the paper discussed the geometric correlation of casting shrinkage deformation and established prediction models for shrinkage allowance coefficient. First, casting experiments and simulations were conducted for H-shaped castings. And the measured pattern allowance coefficients aligned with the simulation results, verifying the reliability of the simulation. Then, the distribution trend of shrinkage along the casting geometric contour was analyzed, and the complex dependence of casting dimensional shrinkage changes on the geometry was discussed. Finally, the paper identified the key geometric parameters that affect shrinkage of each region. And the shrinkage prediction modeling of castings based on geometric parameters was realized. Compared with the conventional constant value for pattern allowance coefficients, the accuracy of the predicted value in assigning shrinkage allowance has been improved by 30.4 pct. The regression model has a good predictive effect on the measured values. The research is beneficial to the dimensional accuracy control in casting production. It can also provide a theoretical basis for the development of shrinkage deformation control technology for complex shape investment castings.

Similar content being viewed by others

References

S. Pattnaik, D.B. Karunakar, and P.K. Jha: J. Mater. Process. Tech., 2012, vol. 212, pp. 2332–48.

R.K. Nayak and S. Venugopal: Mater. Today, 2018, vol. 5, pp. 24997–5005.

D. Wang, A. Dong, G. Zhu, D. Shu, and F. Li: Int. J. Adv. Manuf. Technol., 2018, vol. 96, pp. 623–29.

A. Julio, S. Andre, and K. Oliver: Intermetallics, 2011, vol. 19, pp. 757–61.

K.V. Nikitin, V.N. D’Yachkov, V.I. Nikitin, A.Y. Barinov, and V.B. Deev: IOP Conf. Ser. Mater. Sci. Eng., 2020, vol. 919, pp. 022041–6.

S. Kumar and D.B. Karunakar: Int. J. Metalcast., 2022, vol. 16, pp. 962–72.

S. Pattnaik: J. Braz. Soc. Mech. Sci., 2018, vol. 40, pp. 1–11.

S.N. Bansode, V.M. Phalle, and S.S. Mantha: Adv. Mech. Eng., 2019, vol. 11, pp. 637–42.

D. Wang, J. Yu, C. Yang, X. Hao, L. Zhang, and Y. Peng: Int. J. Adv. Manuf. Technol., 2022, vol. 119, pp. 691–704.

R.E. Stein, P.G. Sanders, T. Bodick, and R.W. Oehrlein: Int. J. Metalcast., 2023, vol. 17, pp. 604–14.

Y.H. Chen, D.M. Liao, W.D. Li, T. Chen, M. Yang, and J.K. Shi: China Foundry, 2022, vol. 19, pp. 342–50.

A.S. Sabau and W.D. Porter: Metall. Mater. Trans. B, 2008, vol. 39, pp. 317B–30.

P. Tao, H. Shao, Z. Ji, N. Hai, and Q. Xu: Prog. Nat. Sci., 2018, vol. 28, pp. 520–28.

Y.W. Dong, P.F. Shao, X. Guo, B. Xu, C.P. Yin, and Z.Y. Tan: J. Iron. Steel Res. Int., 2023, vol. 30, pp. 2010–20.

R. Kumar, S. Madhu, K. Aravindh, V. Jayakumar, G. Bharathiraja, and A. Muniappan: Mater. Today, 2020, vol. 22, pp. 799–805.

G.L. Tian, K. Bu, D.Q. Zhao, Y.L. Zhang, F. Qiu, X.D. Zhang, and S.J. Ren: Int. J. Adv. Manuf. Technol., 2018, vol. 96, pp. 1035–44.

Y. Dong, X. Guo, Q. Ye, and W. Yan: Int. J. Adv. Manuf. Technol., 2022, vol. 118, pp. 4073–84.

M. Mavromihales, J. Mason, and W. Weston: J. Mater. Process. Tech., 2003, vol. 134, pp. 279–86.

S. Ren, K. Bu, S. Mou, R. Zhang, and B. Bai: J. Manuf. Process., 2023, vol. 99, pp. 548–62.

K. Bu, G.L. Tian, F. Qiu, D.Q. Zhao, X.D. Zhang, J.W. Tian, Z.H. Wang, and J. Hu: Int. J. Adv. Manuf. Technol., 2017, vol. 93, pp. 2933–42.

A. Walale, A.S. Chauhan, A. Satyanarayana, G. Venkatachalam, and R. Pradyumna: Mater. Today, 2018, vol. 5, pp. 19471–9479.

M.M.A. Rafique and J. Iqbal: Int. J. Heat Mass Transfer, 2009, vol. 52, pp. 2132–39.

Y.W. Dong, X.L. Li, Q. Zhao, J. Yang, and M. Dao: J. Mater. Process. Tech., 2017, vol. 244, pp. 190–203.

L. Natrayan and M.S. Kumar: Mater. Today, 2020, vol. 27, pp. 306–10.

Acknowledgments

This work was supported by the National Science and Technology Major Project (Grant No. J2019-VII-0013-0153). The authors are grateful for the financial supports.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Bu, K. & Liu, C. Prediction of Shrinkage Allowance Coefficient of Investment Castings Based on Geometric Parameters. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03079-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03079-1