Abstract

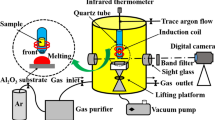

An improved sessile drop method was used to measure the dynamic nonreactive wetting behavior of different titanium concentrations interstitial-free molten steel on an alumina substrate at 1550 ºC, and the interfacial tension was also calculated by Young’ equation based on the measured surface tension and the static contact angle compared to the previous sessile drop method. And the discrepancies were investigated by analyzing the interface layer between the melt and the alumina substrate with different oxygen partial pressures. Furthermore, it was discussed for the forces analysis of the dynamic contact angle for the improved sessile drop method and the interface layer reactive for the improved sessile drop method. The results demonstrate that the advancing angle, receding and static contact angles between the flowing melt and the solid substrate were quickly obtained by the improved sessile drop method. And the interfacial tension between molten steel and alumina substrate, which is 1428.71 and 1221.35 mN/m, respectively, with titanium concentrations of 280 ppm and 540 ppm for the improved sessile drop method, is higher than for the previous sessile drop method, which is 1245.56 and 719.01 mN/m, respectively. The low alloy interstitial-free molten steel and alumina substrate had formed an interface layer for the previous sessile drop method, and the thickness of the interface layer increased from 3.5 to 77.8 μm with a titanium concentration of 540 ppm as the oxygen partial pressure increased from 5.4 × 10−23 to 5.4 × 10−19 atm. The interface layer, which is composed of alloy compounds such as silicon, manganese and titanium oxides, is sensitive to the active alloy of interstitial-free molten steel and oxygen partial pressure.

Similar content being viewed by others

References

D.X. Yin, M.A. Pei-Sheng, and S.Q. Xia: Bull. Sci. Technol., 2007, vol. 23, pp. 424–29.

A.A. Amadeh, J.C. Labbe, and P.E. Quintard: J. Eur. Ceram. Soc., 2005, vol. 25, pp. 1041–48.

H. Ohba and K. Sugita: J. Ceram. Soc. Jpn., 1963, vol. 71, pp. 207–13.

J. Kurikkala, O. Mattila, T. Fabritius, and J. Härkki: ISIJ Int., 2010, vol. 50, pp. 356–62.

Q. Shu, T. Alatarvas, V. Visuri, and T. Fabritius: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1818–29.

K. Sasai: ISIJ Int., 2016, vol. 56, pp. 1013–22.

C. Lu, W. Wang, J. Zeng, C. Zhu, and J. Chang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 77–85.

J.M. Ludwicki, F.L. Robinson, and P.H. Steen: ACS Appl. Mater. Interfaces, 2020, vol. 12, pp. 22115–19.

P.S. Marquis de Laplace: Traité de Mécanique Céleste, Courcier, Paris, 1805.

T. Young: Philos. Trans. R. Soc. Lond., 1805, vol. 95, pp. 65–87.

H. Daikoku, S. Kawanishi, T. Ishikawa, and T. Yoshikawa: J. Chem. Thermodyn., 2021, vol. 160, p. 106476.

J.P. Anson, R. Drew, and J.E. Gruzleski: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 1027–32.

M.G. Cabezas, A. Bateni, J.M. Montanero, and A.W. Neumann: Langmuir, 2006, vol. 22, pp. 10053–60.

B. Gallois and C. Lupis: Metall. Mater. Trans. B, 1981, vol. 12B, pp. 549–57.

J. Lee, T. Tanaka, M. Yamamoto, and S. Hara: Mater. Trans., 2005, vol. 45, pp. 625–29.

J. Schmitz, J. Brillo, I. Egry, and R. Schmid-Fetzer: Int. J. Mater. Res., 2013, vol. 100, pp. 1529–35.

Tolman; and C. Richard: J. Chem. Phys., 1949, vol. 17, pp. 333–37.

S.C. Hardy: J. Cryst. Growth, 1984, vol. 69, pp. 456–60.

S. Ozawa, S. Takahashi, S. Suzuki, H. Sugawara, and H. Fukuyama: Jap. J. Appl. Phys., 2011, vol. 50, p. 11.

S. Ozawa, S. Takahashi, N. Watanabe, and H. Fukuyama: Int. J. Thermophys., 2014, vol. 35, pp. 1705–11.

Q. Li, H. Zhang, M. Gao, J. Li, and H. Zhang: J. Mater. Process. Tech., 2021, vol. 294, p. 117094.

L. Liu, T.H. Wang, J.C. Li, and Q. Jiang: Solid State Commmun., 2012, vol. 15, pp. 573–76.

X.U. Qian-Gang, Z. Hai-Feng, and H.U. Zhuang-Qi: Trans. Nonferr. Metal. Soc., 2005, vol. 15, pp. 45–50.

B. Yildiz and V. Bashiry: J. Adhes., 2018, vol. 95, pp. 929–42.

M. Kishimoto, K. Mori, and Y. Kawai: ISIJ Int., 1984, vol. 48, pp. 413–17.

L.C. Zhong, M. Zeze, and K. Mukai: Acta Metall. Sin., 2004, vol. 17, pp. 795–804.

M. Divakar, J.P. Hajra, A. Jakobsson, and S. Seetharaman: Metall. Mater. Trans. B, 2000, vol. 31, pp. 267–76.

K. Ogino, K. Nogi, and C. Hosoi: Tetsu- to- Hagane, 1983, vol. 69, pp. 1989–94.

T. Yokoyama, Y. Ueshima, K. Sasai, Y. Mizukami, H. Kakimi, and M. Kato: Tetsu- to- Hagane, 1997, vol. 83, pp. 563–68.

J. Lee, Y. Kim, J. Choe, and M. Abbasi: AISTech 2013, 2013, vol. 1, pp. 1117–22.

N. Eustathopoulos: Acta Mater., 1998, vol. 46, pp. 2319–27.

K.C. Mills, E.D. Hondros, and Z. Li: J. Mater. Sci., 2005, vol. 40, pp. 2403–409.

C. Wan, P. Kritsalis, B. Drevet, and N. Eustathopoulos: Mater. Sc. Eng. A, 1996, vol. 207, pp. 181–87.

P. Kritsalis, B. Drevet, N. Valignat, and N. Eustathopoulos: Scr. Metall. Mater., 1994, vol. 30, pp. 1127–32.

K. Landry, C. Rado, and N. Eustathopoulos: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3181–86.

K. Landry, C. Rado, and R. Voitovich: Acta Mater., 1997, vol. 45, pp. 3079–85.

A. Karasangabo and C. Bernhard: J. Adhes. Sci. Technol., 2012, vol. 26, pp. 1141–56.

X. Cai, Y. Bao, L. Lin, and C. Gu: Steel Res. Int., 2015, vol. 87, pp. 1168–78.

C.H. Chang, I.H. Jung, S.C. Park, H.S. Kim, and H.G. Lee: Ironmak. Steelmak., 2013, vol. 32, pp. 251–57.

C. Wang, N. Verma, Y. Kwon, W. Tiekink, N. Kikuvhi, and S. Sridhar: ISIJ Int., 2011, vol. 51, pp. 375–81.

C. Xuan, W. Mu, Z.I. Olano, P.G. Jnsson, and K. Nakajima: Steel Res. Int., 2016, vol. 87, pp. 911–20.

C.G.L. Furmidge: J. Colloid Interface Sc., 1962, vol. 17, pp. 309–24.

M. Remer, M. Psarski, K. Gumowski, J. Rokicki, G. Sobieraj, M. Kaliush, D. Pawlak, and G. Celichowski: Colloids Surf. A, 2016, vol. 508, pp. 57–69.

S. Sikalo, H.D. Wilhelm, I.V. Roisman, S. Jakirli, and C. Tropea: Phys. Fluids, 2005, vol. 17, pp. 62103.

S.F. Lunkad, V.V. Buwa, and K. Nigam: Chem. Eng. Sci., 2007, vol. 62, pp. 7214–24.

J. Fukai, Z. Zhao, D. Poulikakos, C.M. Megaridis, and O. Miyatake: Phys. Fluids A, 1993, vol. 5, pp. 2588–99.

D. Roux and J.J. Cooper-White: J. Colloid Interf. Sci., 2004, vol. 277, pp. 424–36.

B. Deo, and R. Boom: Prentice Hall International, London, UK, 1993.

W.Y. Kim, J.O. Jong-Oh, C.O. Lee, D.S. Kim, and J.J. Pak: ISIJ Int., 2008, vol. 48, pp. 17–22.

W.C. Doo, D.Y. Kim, and K. Yi: Met. Mater. Int., 2007, vol. 13, pp. 249–55.

S. Basu, S.K. Choudhary, and N.U. Girase: ISIJ Int., 2004, vol. 44, pp. 1653–660.

M. Kudoh, K. Ohsasa, K. Tanaka, and K. Okuyama: Bull. Faculty Eng. Hokkaido University, 1992, vol. 162, pp. 191–202.

Acknowledgments

The financial support from the National Key Research and Development Program of China (No. 2021YFB3702401), the Hunan Scientific Technology Projects (No. 2020WK2003), and the National Science Foundation of China (No. 52130408) are greatly acknowledged.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Long, Q., Wang, W. & Gao, X. Measuring Dynamic Nonreactive Wetting Behavior Between Interstitial-Free Molten Steel and Alumina. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03065-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03065-7