Abstract

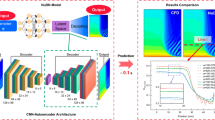

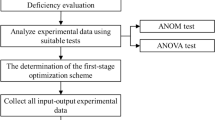

In this paper, a neural network model is introduced, which uses Convolutional Neural Network model optimized by Genetic Algorithm (GA-CNN) to predict the liquid level fluctuation of continuous casting mold in real time. The experimental data were obtained from the practical production process of an iron and steel plant in China. For the two-stream continuous caster in this factory, two sets of mold liquid level fluctuation value data sets were established. These data sets are categorized into the first- and the second-stream mold liquid surface fluctuation data set. Both data sets comprise 138 production parameters along with the mold liquid level fluctuation values. Random Forest feature screening and data preprocessing are carried out on the data set, so that the processed data can be learned and trained by the model, thus obtaining the mold liquid level fluctuation prediction model. To facilitate the analysis, the sensitivity analysis of related continuous casting production parameters and mold level fluctuation data was carried out. Subsequently, the influence of production parameters on the fluctuation value of mold liquid level was investigated by characteristic thermal diagram and Shapley additional explanations diagram, and the influence degree of each parameter on the model performance was determined. The results indicate that the GA-CNN model demonstrates strong predictive capability, with a high correlation coefficient (R2) of 0.98, a low mean absolute error (MAE) of 0.1093, and a mean square error (MSE) of 0.0225. Notably, the position of the stopper was identified as a critical factor significantly affecting mold level fluctuations. The model has high prediction accuracy and can meet the needs of practical application in steel plants.

Similar content being viewed by others

References

S.Y. Lee, B.A. Tama, C. Choi, J.-Y. Hwang, J. Bang, and S. Lee: IEEE Access, 2020, vol. 8, pp. 21953–65.

C. David, C. Sandra, G. Heimo, P. Ashwini, L. Thomas, B. Matthias, K. Gerald, and K. Roman: Intell. Manuf., 2022, vol. 33, pp. 1561–79.

L. Hong, L. Juanjuan, T. Guofeng, Z. Hongwei, J. Zhongkuai, and L. Pu: JOM, 2023, vol. 75, pp. 914–19.

X. Meng, L. JuanJuan, L. Hong, L. Qiang, and Z. XiuChun: Metall. Autom., 2023, vol. 47, pp. 66–72.

F. Ying, W. Min, C. Xin, C. Luefeng, and D. Sheng: Inf. Sci., 2020, vol. 539, pp. 487–504.

C. Wei, Z. Lifeng, W. Yadong, J. Sha, and Y. Wen: Powder Technol., 2021, vol. 390, pp. 539–55.

Y. Hai-qi, Z. Miao-yong, and W. Jun: J. Iron. Steel Res. Int., 2010, vol. 17(4), pp. 7–12.

R. Bartos, S. Berockmann, R. Fandrich, G. Endemann, J. T. Ghenda, S. Heinzel, K. Letz, H. B. Lungen, G. Moninger, U. Stellmacher, H. J. Wieland, K. R. Winkelgrund, and H. Wockner: Stahlfibel. Germany: Verlag Stahleisen GmbH, Düsseldorf, 2007, pp. 8–12.

J. Zhaohui, D. Jinzong, P. Dong, W. Tianyu, and G. Weihua: Measurement, 2022, vol. 204, pp. 112155–65.

Y. LeCun, B. Boser, J.S. Denker, D. Henderson, R.E. Howard, W. Hubbard, and L.D. Jackel: Neural Comput., 1989, vol. 1, pp. 541–51.

F. Gerges, G. Zouein, and D. Azar: In Proceedings of the 2018 International Conference on Computing and Artificial Intelligence,, 2018, pp 19–22.

F. Mumali: Comput. Ind. Eng., 2022, vol. 165, pp. 107964–69.

H. Dae-geun, H. Woong-hee, and Y. Chang-Hee: Metall. Mater. Trans. B, 2021, vol. 52, pp. 3833–45.

A. Kordijazi, T. Zhao, J. Zhang, K. Alrfou, and P. Rohatgi: JOM, 2021, vol. 73, pp. 2060–74.

S. Gupta and L. Li: JOM, 2022, vol. 74, pp. 414–28.

A. Meghlaoui, R.T. Bui, L. Tikasz, J. Thibault, and R. Santerre: Metall. Mater. Trans. B, 1998, vol. 29, pp. 1007–19.

W. Cardoso, R. di Felice, and R.C. Baptista: Mater. Res. Ibero-Am. J. Mater., 2022, vol. 25, pp. 1516–2439.

G. MaoQiang, X. AnJun, L. Xuan, and W. HuiXian: Chin. J. Eng., 2022, vol. 44, pp. 12–20.

T.K. Erdem, O. Cengiz, and G. Tayfur: Arab. J. Sci. Eng., 2020, vol. 45, pp. 3671–81.

S. Singhal, S.A. Khan, M. Muaz, and E. Ahmed: Mater. Today, 2023, vol. 72, pp. 1102–09.

C. Nagarjuna, S.K. Dewangan, A. Sharma, K. Lee, S.J. Hong, and B. Ahn: Met. Mater., 2023, vol. 29, pp. 1968–75.

D. Haiyang, W. Xudong, B. Yu, Y. Man, and G. Qingtao: Metall. Mater. Trans. B, 2019, vol. 50, pp. 2343–53.

E. Maleki and O. Unal: Met. Mater., 2021, vol. 27, pp. 262–76.

L. Zhao, C. Shusen, and L. Pengbo: High Temp. Mater. Proces., 2022, vol. 41, pp. 505–13.

W. Weijian, Z. Lifeng, R. Ying, L. Yan, S. Xiaohui, and Y. Wen: Metall. Mater. Trans. B, 2022, vol. 53, pp. 1–7.

S. Wenbin, L. Zhufeng, Y. Ladao, and H. Qiao: Metals, 2019, vol. 9, pp. 458–60.

H. Gao, P. Hao, and S. Liu: In 2020 5th International Conference on Mechanical, Control and Computer Engineering (ICMCCE), Harbin 2020, pp 5–10.

T. ChaoNan, X. Lei, P. KaiXiang, and L. JiangYun: Control Decis. Mak., 2009, vol. 24, pp. 5–10.

S.R.P. Debasish and K.T. Prabhat: J. Intell. Manuf., 2019, vol. 30, pp. 241–54.

X. Zi-cheng, Z. Jiang-shan, Z. Jun-guo, Z. Jin, J. Yu, and L. Qing: Metall. Mater. Trans. B, 2023, vol. 54, pp. 1181–94.

S.C. Chelgani, H. Nasiri, A. Tohry, and H.R. Heidari: Powder Technol., 2023, vol. 420, pp. 118416–20.

R. Genuer, J.M. Poggi, and C. Tuleau-Malot: Pattern Recogn. Lett., 2010, vol. 31, pp. 2225–36.

D.T. Pham, P.Q. Cuong, T.T. Ngoc, N.B.K. Do, and K.P. Cong: Internet Things, 2023, vol. 22, pp. 100813

C. Ziwei, W. Minghao, W. Hao, L. Lili, and W. Xidong: Metall. Mater. Trans. B, 2022, vol. 53, pp. 2018–29.

L. Yanbin, Z. Wen, Q. Guangjie, and Z. Jiangpeng: Procedia Comput. Sci., 2022, vol. 214, pp. 1603–16.

L. Aihua, F. Mengyan, L. Yanruyu, and L. Zhidong: Procedia Comput. Sci., 2016, vol. 91, pp. 245–51.

M.S. Martiello, R.C. Daniel, A. Edesio, B. Tiago, C.P.L.F.D.C. André, and D.Z. Edgar: Acta Mater., 2022, vol. 240, pp. 118302–12.

Acknowledgements

The work was supported by Special Funding Projects for Local Science and Technology Development guided by the Central Committee (No. YDZJSX2022C028), the Fundamental Research Program of Shanxi Province (Nos. 20210302123218, 202203021211187), Innovation and Entrepreneurship Training Program for College Students in Shanxi Province (202210109006), and the Foundation of State Key Laboratory of Advanced Metallurgy, USTB (K22-10).

Fundings

Special Funding Projects for Local Science and Technology Development guided by the Central Committee (No. YDZJSX2022C028), Fundamental Research Program of Shanxi Province (Nos. 20210302123218, 202203021211187), the Foundation of State Key Laboratory of Advanced Metallurgy, USTB (K22-10), and Innovation and Entrepreneurship Training Program for College Students in Shanxi Province (202210109006).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, Y., Zhou, H., Zhang, B. et al. Prediction Model of Liquid Level Fluctuation in Continuous Casting Mold Based on GA-CNN. Metall Mater Trans B (2024). https://doi.org/10.1007/s11663-024-03036-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11663-024-03036-y