Abstract

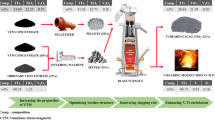

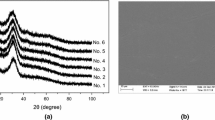

Vanadium–titanium magnetite is a complex ore with iron, vanadium, titanium, and other valuable elements, and it is of great significance to recycle the valuable elements. HIsmelt smelting reduction of vanadium–titanium magnetite is a clean and effective ironmaking process. The effect of TiO2 content on the viscosity of CaO–SiO2–Al2O3–MgO–TiO2–FeO slag system is studied by rotating cylinder method. The composition and microstructure of crystalline phase are analyzed by XRD and SEM–EDS, and compared with the thermodynamic calculation results of FactSage8.1. The results show that the viscosity of molten slag decreased with the increase of TiO2 content, and TiO2 content has a great impact on the viscosity, when the TiO2 content in the slag is less than 20 pct and the temperature is less than 1395 °C. With the increase of TiO2 content, the diffraction peak of perovskite is enhanced, the gehlenite and akermanite are gradually reduced, the shape of perovskite changes from irregular polygon to needle dendrite, and the number also increases gradually. When the TiO2 content reaches 20 pct, the perovskite reaches saturation state. With the increase of TiO2 content, the main precipitates change from perovskite, gehlenite, and akermanite to perovskite, anorthite, and titania spinel. Titanium existed in the slag as perovskite first, and then as baikovite and titanium spinel. Therefore, for high-titanium slag, the TiO2 content has little effect on the fluidity of HIsmelt process slag.

Similar content being viewed by others

References

C. Feng, M.S. Chu, J. Tang, Y.T. Tang, and Z.G. Liu: Steel Res. Int., 2016, vol. 87, pp. 1274–83. https://doi.org/10.1002/srin.201500355.

W.L. Nie, X.Y. Yang, Z.F. He, Y.W. Yang, X. Luo, Q.D. Li, and M.Z. Yu: Met. World, 2022, https://doi.org/10.3969/j.issn.1000-6826.2020.12.2801.

L. Starkey: ASEG Extended Abstracts, 1994, pp. 383–90. https://doi.org/10.1071/ASEGSpec07_28.

L.L. Chen: China Resour. Compr. Util. (China), 2015, vol. 33, pp. 31–33.

K.J. Hu, J. Yao, and Q. Xi: World Nonferrous Metals, 2008, (1), pp. 36–42.

X.D. Wang, W. Wei, X.B. Lv, X.J. Fan, S.B. Wang, and Y. Liu: Geol. J., 2017, vol. 53, pp. 1823–39. https://doi.org/10.1002/gj.3009.

J. Fang: Non-blast Furnace Ironmaking Technology and Theory, 2nd ed. Metallurgical Industry Press, Beijing, 2010, pp. 179–80.

J.L. Zhang, Z.J. Liu, and T.J. Yang: Non-blast Furnace Ironmaking, Metallurgical Industry Press, Beijing, 2015.

Y.C. Zhao, Y.Y. Chu and C.S. Huang: Ind. Heat., 2018, vol. 47, pp. 18–20 + 33. https://doi.org/10.3969/j.issn.1002-1639.2018.06.006.

S.B. Xu and H.F. Xu: China Metall., 2016, vol. 26, pp. 33–39. https://doi.org/10.13228/j.boyuan.issn1006-9356.20160028.

N. Goodman and R. Dry: Proc. 5th Int. Congr. Sci. Technol. Ironmak., 2009, pp. 349–54.

M. Wang, R.X. Ren, H.W. Dong, G.J. Zhang, and S.Y. Liu: Iron Steel (China), 2020, vol. 55, pp. 145–50. https://doi.org/10.13228/j.boyuan.issn0449-749x.20190550.

S.G. Xu, Z.M. Li, and Q. Lyu: Ironmaking (China), 2007, vol. 26, pp. 59–62.

J.L. Zhang, G.Q. Zhang, Z.J. Liu, Z.H. Wang, K.J. Li, and X.B. Zhang: China Metall. (China), 2018, vol. 28, pp. 37–41 + 46. https://doi.org/10.13228/j.boyuan.issn1006-9356.20180021.

J. Liu and Z.H. Peng: Ironmaking (China), 2022, vol. 41, pp. 54–61.

Z. Wang, Z. Li, M. Zhong, Z. Li, and C. Wang: J. Non-Cryst. Solids, 2023, https://doi.org/10.1016/j.jnoncrysol.2022.122071.

Z. Pang, Y. Jiang, X. Lv, Z. Yan, and W. He: 10th International Symposium on High-Temperature Metallurgical Processing, 2019, pp. 531–38.

Z. Wang, J. Zhang, M. Zhong, and C. Wang: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1364–70. https://doi.org/10.1007/s11663-022-02507-4.

Z. Wang and I. Sohn: J. Am. Ceram. Soc., 2018, vol. 101, pp. 4285–96. https://doi.org/10.1111/jace.15559.

J. Yang and I. Sohn: J. Mater. Sci. Technol., 2022, vol. 131, pp. 195–203. https://doi.org/10.1016/j.jmst.2022.05.037.

Z. Wang and I. Sohn: Ceram. Int., 2020, vol. 46, pp. 903–12. https://doi.org/10.1016/j.ceramint.2019.09.048.

J. Ma, W. Li, G.Q. Fu, and M.Y. Zhu: ISIJ Int., 2020, vol. 60, pp. 2408–18. https://doi.org/10.2355/isijinternational.ISIJINT-2020-244.

Z. Yan, X.W. Lv, W.C. He, and J. Xu: ISIJ Int., 2017, vol. 57, pp. 31–36. https://doi.org/10.2355/isijinternational.ISIJINT-2016-420.

K.X. Jiao, J.L. Zhang, Z.Y. Wang, C.L. Chen, and Y.X. Liu: Steel Res. Int., 2017, vol. 88, p. 1200296. https://doi.org/10.1002/srin.201600296.

S.S. Zhang, P. Hu, J.T. Rao, Z.Y. Wang, Y.B. Zong, and J.L. Zhang: Metals, 2022, vol. 12, p. 1019. https://doi.org/10.3390/met12061019.

Z. Wang, H.Y. Sun, and Q.S. Zhu: Int. J. Miner. Metall. Mater., 2019, vol. 26, pp. 1120–28. https://doi.org/10.1007/s12613-019-1830-9.

T.L. Li, C.Y. Sun, D. Lan, J. Song, S. Song, and Q. Wang: ISIJ Int., 2019, vol. 59, pp. 245–52. https://doi.org/10.2355/isijinternational.ISIJINT-2018-498.

H.B. Ma, K.X. Jiao, J.L. Zhang, Y.B. Zong, J. Zhang, and S. Meng: Ceram. Int., 2021, vol. 47, pp. 17445–54. https://doi.org/10.1016/j.ceramint.2021.03.061.

Z. Wang, X.W. Liu, L. Zhang, and Q.S. Zhu: Trans. Indian Inst. Met., 2015, vol. 69, pp. 97–105. https://doi.org/10.1007/s12666-015-0720-8.

H.B. Ma, K.X. Jiao, and J.L. Zhang: CrystEngComm, 2022, vol. 22, pp. 361–70. https://doi.org/10.1039/c9ce01695c.

Z.J. Wang and I. Sohn: ISIJ Int., 2020, vol. 60, pp. 2705–16. https://doi.org/10.2355/isijinternational.ISIJINT-2019-522.

V. Carles, P. Alphonse, P. Tailhades, and A. Rousset: Thermochim. Acta, 1999, vol. 334, pp. 107–13.

B. Boyanov and D. Xhadzhie: Thermochim. Acta, 1985, vol. 93, pp. 89–92.

Y. Zhou, Y.M. Gao, X.J. Ma, X. Zheng, M. Wang, and B. Wang: J. Wuhan Univ. Sci. Technol., 2013, vol. 36, pp. 383–86.

D. Yang, H.H. Zhou, J. Wang, Z.D. Pang, G.S. Pei, Z.M. Yan, H.X. Mao, G.B. Qiu, and X.W. Lv: J. Mater. Res. Technol., 2021, vol. 12, pp. 1615–22. https://doi.org/10.1016/j.jmrt.2021.03.069.

J.B. Kim and I. Sohn: ISIJ Int., 2014, vol. 54, pp. 2050–58. https://doi.org/10.2355/isijinternational.54.2050.

I. Sohn, W. Wang, H. Matsuura, F. Tsukihashi, and D.J. Min: ISIJ Int., 2012, vol. 52, pp. 158–60. https://doi.org/10.2355/isijinternational.52.158.

Z. Tong, J. Wang, C. Xu, and Z. Xie: Nonferr. Met. Sci. Eng., 2023, pp. 1–14 (Online). https://kns.cnki.net/kcms/detail/36.1311.TF.20230607.1453.006.html.

G.X. Qiu, D.J. Miao, M.C. Cai, X.M. Li, D.P. Zhan, and Y.F. Liu: Iron Steel (China), 2022, vol. 57, pp. 42–52. https://doi.org/10.13228/j.boyuan.issn0449-749x.20220281.

A.Y. Ilyushechkin, S.S. Hla, D.G. Roberts, and N.N. Kinaev: J. Non-Cryst. Solids, 2011, vol. 357, pp. 893–902. https://doi.org/10.1016/j.jnoncrysol.2010.12.004.

A. Ilyushechkin and A. Kondratiev: J. Rheol., 2019, vol. 63, pp. 719–33. https://doi.org/10.1122/1.5095968.

Acknowledgments

This study was supported by the High-End Iron and Steel Metallurgy Joint Fund Project of Hebei Natural Science Foundation (No. E2020209208), Chengde Science and Technology Plan (No. 202205B060), and Tangshan Science and Technology Plan (No. 22130203H).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Y.J., Liu, R., Wang, Y. et al. Viscosity of CaO–SiO2–Al2O3–MgO–TiO2–FeO Slag in HIsmelt Process: Influence of TiO2 Content on Viscosity and Crystallization. Metall Mater Trans B 54, 3288–3298 (2023). https://doi.org/10.1007/s11663-023-02907-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02907-0