Abstract

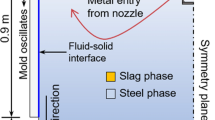

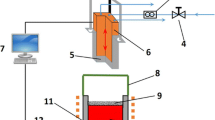

Properly coordinating the initial solidification and heat transfer behavior of the meniscus of the mold is crucial for stabilizing and improving the surface quality of continuous casting slabs. The study comprehensively considers the geometric, contact, and motion characteristics of the meniscus under mold periodic oscillation, and develops a three-dimensional numerical model that couples the heat transfer of molten steel, shell solidification, and multiphase flow. The transient periodic heat transfer behavior of the meniscus in the mold is simulated and analyzed. The investigation begins with analyzing the distribution and variation of heat flux, and then focuses on analyzing the effects of steel level height, upper backflow, and thickness of mold flux on the formation of local high heat flux regions, periodic severe fluctuations, and sharp changes in corner heat flux. The transient variation and signal characteristics of heat flux near the meniscus are analyzed through Fast Fourier Transform (FFT) and Power Spectral Density (PSD). The analysis reveals that the high steel level with circulation is the main factor contributing to the formation of a local high heat flux zone. The flow patterns of molten steel and the uneven distribution of solid slag film can result in discontinuities in the region of sharp fluctuations. The variation of transient heat flux is affected by the relative motion between the initial solidified shell and the copper plate in the meniscus. The low-frequency heat flux is closely related to the melt flow fluctuations and the shell solidification, while the high-frequency heat flux is introduced by the mold oscillation. The signal difference of the heat flux near the meniscus is determined by its solidification rate and height. The results are beneficial for monitor the formation of initial solidification shell defects of the meniscus.

Similar content being viewed by others

References

M. Suzuki, M. Suzuki, and M. Nakada: ISIJ Int., 2001, vol. 41, pp. 670–82.

S. Harada, S. Tanaka, H. Misumi, S. Mizoguchi, and H. Horiguchi: ISIJ Int., 1990, vol. 30, pp. 310–16.

X.J. Zuo, R.G. Lin, N. Wang, J. Yang, X.N. Meng, and M.Y. Zhu: Steel Res. Int., 2016, vol. 87, pp. 413–23.

P.E.R. Lopez, K.C. Mills, P.D. Lee, and B. Santillana: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 109–22.

J. Sengupta, B.G. Thomas, H.J. Shin, G.G. Lee, and S.H. Kim: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1597–1611.

H. Mizukami, Y. Shirai, and S. Hiraki: ISIJ Int., 2020, vol. 60, pp. 1968–77.

P.E.R. Lopez, P.N. Jalali, U. Sjöström, P.G. Jönsson, K.C. Mills, and I. Sohn: ISIJ Int., 2018, vol. 58, pp. 201–10.

X.Z. Zhang, X.R. Zheng, Q.G. Liu, and X.K. Li: J. Iron Steel Res. Int., 2013, vol. 20, pp. 19–24.

H.J. Shin, S.H. Kim, B.G. Thomas, G.G. Lee, J.M. Park, and J. Sengupta: ISIJ Int., 2006, vol. 46, pp. 1635–44.

A. Yamauchi, S. Itoyama, Y. Kishimoto, H. Tozawa, and K. Sorimachi: ISIJ Int., 2002, vol. 42, pp. 1094–1102.

A. Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 355–71.

A. Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, M. Byrne, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 373–83.

E.Y. Ko, J. Choi, J.Y. Park, and I. Sohn: Met. Mater. Int., 2014, vol. 20, pp. 141–51.

J.Y. Park, E.Y. Ko, J. Choi, and I. Sohn: Met. Mater. Int., 2014, vol. 20, pp. 1103–14.

Y. Liu, W. Wang, F. Ma, and H. Zhang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1419–30.

F. Ma, Y. Liu, W. Wang, and H. Zhang: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 1902–11.

W. Wang, C. Zhu, and L. Zhou: Steel Res. Int., 2017, vol. 88, p. 1600488.

L. Yu, S. Pei, W.L. Wang, and H.H. Zhang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 247–59.

L. Yu, S. Pei, W.L. Wang, X. Long, K. Zhang, E. Gao, and R. Qin: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 78–88.

X. Li, Z. Zhang, M. Lv, M. Fang, and K. Liu: Steel Res. Int., 2022, vol. 93, p. 2100673.

H. Chen, M. Long, D. Chen, T. Liu, and H. Duan: Int. J. Heat Mass Transf., 2018, vol. 126, pp. 843–53.

W. Chen, L. Zhang, Y. Wang, Y. Ren, Q. Ren, and W. Yang: Int. J. Heat Mass Transf., 2022, vol. 190, p. 122789.

H. Yang, P.E.R. Lopez, and D.M. Vasallo: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2760–85.

B.G. Thomas: Steel Res. Int., 2018, vol. 89, p. 1700312.

P.E.R. Lopez, P.D. Lee, and K.C. Mills: ISIJ Int., 2010, vol. 50, pp. 425–34.

P.E.R. Lopez, P.D. Lee, K.C. Mills, and B. Santillana: ISIJ Int., 2010, vol. 50, pp. 1797–1804.

A.S.M. Jonayat and B.G. Thomas: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1842–64.

J. Yang, Z.Z. Cai, and M.Y. Zhu: ISIJ Int., 2018, vol. 58, pp. 299–308.

J. Yang, X.N. Meng, and M.Y. Zhu: ISIJ Int., 2018, vol. 58, pp. 2071–78.

S. Zhang, Q. Wang, S. He, and Q. Wang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 2038–49.

X. Zhang, W. Chen, P.R. Scheller, Y. Ren, and L. Zhang: JOM, 2019, vol. 71, pp. 78–87.

Y. Deng, Y. Zhang, Q.Q. Wang, and Q. Wang: JOM, 2018, vol. 70, pp. 2909–16.

X. Zhang, W. Chen, Y. Ren, and L. Zhang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 1444–60.

X. Zhang, Z. Dan, W. Chen, L. Zhang, and Q. Wang: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 322–38.

J. Ji, Y. Cui, X. Zhang, Q.Q. Wang, S. He, and Q. Wang: Steel Res. Int., 2021, vol. 92, p. 2000636.

J. Ji, Y. Mao, X. Zhang, W. Chen, L. Zhang, and Q. Wang: Steel Res. Int., 2021, vol. 92, p. 2000714.

J.U. Brackbill, D.B. Kothe, and C. Zemach: J. Comput. Phys., 1992, vol. 100, pp. 335–54.

C. Ojeda, J. Sengupta, B.G. Thomas, J. Barco, and J.L. Arana: AISTech, 2006, vol. 1, pp. 1017–28.

X.D. Wang, L.W. Kong, M. Yao, and X.B. Zhang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 357–66.

Q.Q. Wang and L.F. Zhang: JOM, 2016, vol. 68, pp. 2170–79.

M. Hanao, M. Kawamoto, and A. Yamanaka: ISIJ Int., 2009, vol. 49, pp. 365–74.

M. Suzuki, S. Miyahara, T. Kitagawa, S. Uchida, T. Mori, and K. Okimoto: Tetsu-to-Hagane J. Iron Steel Inst. Jpn, 1992, vol. 78, pp. 113–20.

H. Zhang, W. Wang, F. Ma, and L. Zhou: Metall. Mater. Trans. B, 2015, vol. 46B, pp. 2361–73.

R.B. Mahapatra, J.K. Brimacombe, and I.V. Samarasekera: Metall. Mater. Trans. B, 1991, vol. 22B, pp. 875–88.

Y.A. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 685–706.

A. Yamauchi, T. Emi, and S. Seetharaman: ISIJ Int., 2002, vol. 42, pp. 1084–93.

X.D. Wang, L.W. Kong, F.M. Du, M. Yao, X. Zhang, and M.A. Han: ISIJ Int., 2016, vol. 56, pp. 803–11.

H. Zhang and W. Wang: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 779–93.

Acknowledgments

The present work was financially supported by the National Natural Science Foundation of China under Nos. 51974056 and 51474047.

Conflict of interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wei, ZJ., Wang, XD. & Yao, M. Simulation Study on Transient Periodic Heat Transfer Behavior of Meniscus in Continuous Casting Mold. Metall Mater Trans B 54, 3164–3179 (2023). https://doi.org/10.1007/s11663-023-02899-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02899-x