Abstract

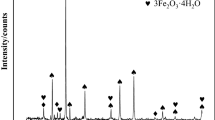

High-quality pellets have been developed from a low-grade Indian chromite overburden containing high silica in the present study. The thermodynamic, hot-stage microscopic, and thermogravimetric analyses of the overburden and pellet mixes predict the temperature of formation of low melting slag phases at various basicity. A temperature in the range of 1200 °C to 1300 °C and basicity between 0.10 and 0.15 have been found ideal for the initiation of the slag phases, whereas higher conditions lead to softening of the pellets. The effect of basicity, binder content, induration temperature, and time on the physical and metallurgical properties of the indurated pellets has been investigated. A binder content of 1 wt pct, basicity of 0.15, induration temperature of 1250 °C, and a time of 20 minutes are optimum to provide the desired properties to the pellets. X-ray diffraction and Scanning Electron Microscopy coupled with Energy Dispersion Spectroscopy analysis reveal that under the optimum conditions, hematite recrystallization and slag formation impart the needed strength (133.8 kg/pellet), porosity (27.8 pct), tumbler index (99.2 pct), RI (76.2 pct), and RDI (1.2 pct). Conversely, increasing the basicity and the induration temperature results in the melting of the slag phases and, therefore, impair the consolidation of the pellets.

Similar content being viewed by others

References

G. Pilla, R.K. Dishwar, S. Agrawal, A.K. Mandal, N.D. Sahu, and O.P. Sinha: J. Min. Metall. Sect. B Metall., 2020, vol. 56, pp. 229–35.

Government of India, Ministry of Mines, Indian Bureau of Mines: Indian Minerals Yearbook 2020 (Part-III: Mineral Reviews), Government of India, Ministry of Mines, Indian Bureau of Mines, Nagpur, 2022.

G.U. Kapure, C.B. Rao, V.D. Tathavadkar, and R. Sen: Ironmak. Steelmak., 2011, vol. 38, pp. 590–96.

S.K. Behera, P.P. Panda, S. Singh, N. Pradhan, L.B. Sukla, and B.K. Mishra: Int. Biodeterior. Biodegrad., 2011, vol. 65, pp. 1035–42.

S. Biswas, S. Chakraborty, M.G. Chaudhuri, P.C. Banerjee, S. Mukherjee, and R. Dey: J. Chem. Technol. Biotechnol., 2014, vol. 89, pp. 1491–1500.

S.K. Behera, S.K. Panda, N. Pradhan, L.B. Sukla, and B.K. Mishra: Bioresour. Technol., 2012, vol. 125, pp. 17–22.

Y.V. Swamy, B.V.R. Murthy, and B.R. Reddy: Min. Metall. Explor., 2000, vol. 17, pp. 223–27.

S. Prasad, M. Kumar, and N.S. Randhawa: Trans. Indian Inst. Met., 2021, vol. 74, pp. 2221–30.

S.B. Kanungo and S.K. Mishra: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 389–99.

S. Dwarapudi, V. Tathavadkar, B.C. Rao, T.K. Sandeep Kumar, T.K. Ghosh, and M. Denys: ISIJ Int., 2013, vol. 53, pp. 9–17.

D. Nayak, N. Ray, N. Dash, S.S. Rath, S. Pati, and P.S. De: Powder Technol., 2021, vol. 380, pp. 408–20.

G.H. Li, X.Q. Li, Y.B. Zhang, G.Q. He, and T. Jiang: Ironmak. Steelmak., 2009, vol. 36, pp. 393–96.

A. Ammasi and J. Pal: Ironmak. Steelmak., 2016, vol. 43, pp. 203–13.

G. Fu, W. Li, M. Chu, and M. Zhu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 114–23.

F.E. Santos, C.H. Borgert, L.R. Neto, J.R. de Oliveira, H.J.F. Filho, J.O. Alves, J.P. Machado, F.F. Grillo, V.B. Telles, and E. Junca: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1664–80.

D. Nayak, N. Ray, N. Dash, S.S. Rath, and S.K. Biswal: J. Cent. South Univ., 2020, vol. 27, pp. 1678–90.

D. Nayak, N. Ray, N. Dash, S.S. Rath, S. Pati, and P.S. De: J. Sustain. Metall., 2021, https://doi.org/10.1007/s40831-021-00410-x.

P. Prusti, S.S. Rath, N. Dash, B.C. Meikap, and S.K. Biswal: Adv. Powder Technol., 2021, vol. 32, pp. 3735–45.

S.N. Sahu, B.C. Meikap, and S.K. Biswal: Sep. Purif. Technol., 2023, vol. 311, p. 123327.

FactSage.com, https://www.factsage.com/, Accessed 27 Sept 2022

B. Monsen, E. Thomassen, I. Brakstad, E. Ringdalen, and P.H. Hoegass: AISTech 2015 Proc., Cleveland, OH. 2015.

M. Gan, Z. Ji, X. Fan, W. Lv, R. Zheng, X. Chen, S. Liu, and T. Jiang: Powder Technol., 2018, vol. 333, pp. 385–93.

Acknowledgments

The authors thank TATA Steel Limited, Jamshedpur, for funding this research and providing valuable technical support. They also thank the Director, CSIR-Institute of Minerals and Materials Technology, Bhubaneswar, for his consent to publish this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nayak, D., Sahu, N., Sahu, D.K. et al. Pelletization of a Low-Grade Indian Chromite Overburden: Optimizing the Induration Parameters and Understanding the Consolidation Behavior. Metall Mater Trans B 54, 3049–3059 (2023). https://doi.org/10.1007/s11663-023-02888-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02888-0