Abstract

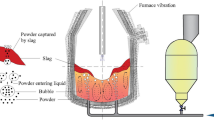

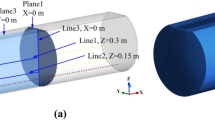

The coupled Eulerian-multifluid VOF-granular flow model was built to simulate gas–liquid-particle three-phase flow in a 120-ton steelmaking converter with bottom powder injection. Particle transport phenomenon and wall scouring behavior is investigated, and effect of bottom-blowing parameters on particle volume fraction and velocity distribution and wall sheer stress are evaluated. Experimental data measured were compared with simulation results to verify accuracy of simulation results, and particle motion and phase interfaces shape are predicted satisfactorily well. Results show that bottom-blowing parameters have a significant influence on particle transport behavior. Increase of powder mass rate contributes to increase of particle velocity, but aggregation of particles occurs at higher powder mass rates. As powder mass rate increases, wall scouring is aggravated. Reduction of particle diameter facilitates the uniformity of particle distribution and weakens the wall scouring. Increase of bottom blowing flow rate improves particle distribution range and accelerates particle velocity, but aggravates wall scouring. Effect of powder injection on scouring of furnace and bottom walls are higher than that of other walls. Bottom injection powder observably increases the mechanical wear of bottom wall. Combined with analysis of simulation results, it is proposed that conditions favorable to powder injection process should be particle diameter not greater than 0.15 mm, particle mass rate not greater than 1.083 kg/s, and bottom blowing flow rate not less than 160 Nm3/h.

Similar content being viewed by others

References

J. Cappel, F. Ahrenhold, M.W. Egger, H. Hiebler, and J. Schenk: Metals, 2022, vol. 12, pp. 912–43.

F. Wallner and E. Fritz: Metall. Res. Technol., 2002, vol. 99, pp. 825–37.

G. Wimmer, K. Pastucha, and E. Wimmer: in The 6th International Congress on the Science and Technology of Steelmaking, ICS, Beijing, 2015, pp. 140–42.

K. Yoshiei, S. Toshikazu, F. Tetsuya, and N. Hiroshi: ISIJ Int., 1988, vol. 28, pp. 746–53.

P. Gittler, R. Kickinger, S. Pirker, E. Fuhrmann, J. Lehner, and J. Steins: Scand. J. Metall., 2000, vol. 29, pp. 166–76.

A.R.N. Meidani, M. Isac, A. Richardson, A. Cameron, and R.I.L. Guthrie: ISIJ Int., 2004, vol. 44, pp. 1639–45.

A. Nordquist, N. Kumbhat, L. Jonsson, and P. Jonsson: Steel Res. Int., 2006, vol. 77, pp. 82–90.

K.Y. Chu, H.H. Chen, P.H. Lai, H.C. Wu, Y.C. Liu, C.C. Lin, and M.J. Lu: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 948–62.

W.J. Wu, H.X. Yu, X.H. Wang, H.B. Li, and K. Liu: J. Iron Steel Res. Int., 2015, vol. 22, pp. 80–86.

J.K. Sun, J.S. Zhang, W.H. Lin, L.L. Cao, X.M. Feng, and Q. Liu: Steel Res. Int., 2021, vol. 92, pp. 2100178–79.

N. Asahara, K.I. Naito, I. Kitagawa, M. Matsuo, M. Kumakura, and M. Iwasaki: Steel Res. Int., 2011, vol. 82, pp. 587–94.

L.L. Cao, Q. Liu, Z. Wang, and N. Li: Ironmak. Steelmak., 2016, vol. 45, pp. 239–48.

O. Olivares, A. Elias, R. Sanchez, M. Diaz-Cruz, and R.D. Morales: Steel Res. Int., 2002, vol. 73, pp. 44–51.

X. Zhou, M. Ersson, L. Zhong, and P. Jönsson: Metall. Mater. Trans. B, 2015, vol. 47B, pp. 434–45.

M. Li, Q. Li, Z. Zou, and B. Li: JOM., 2018, vol. 71, pp. 729–36.

X. Zhou, Y. Liu, P. Ni, and S. Peng: Steel Res. Int., 2020, vol. 92, pp. 2000334–42.

Y. Li, W.T. Lou, and M.Y. Zhu: Ironmak. Steelmak., 2013, vol. 40, pp. 505–14.

H. J. Odenthal, U. Falkenreck, and J. Schlüter: in European Conference on Computational Fluid Dynamics, ed. P. Wesseling, Oñate E. and Périaux J. Delft University of Technology, Netherlands, 2006.

V. Singh, J. Kumar, C. Bhanu, S.K. Ajmani, and S.K. Dash: ISIJ Int., 2007, vol. 47, pp. 1605–12.

J. Zhang, W. Lou, P. Shao, and M. Zhu: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 3585–3601.

J. Zhang, W. Lou, and M. Zhu: Metall. Mater. Trans. B, 2023, vol. 54B, pp. 1449–67.

M. Akhlaghi, V. Mohammadi, N.M. Nouri, M. Taherkhani, and M. Karimi: Chem. Eng. Res. Des., 2019, vol. 152, pp. 48–59.

A. Kumar, D. Ghosh, and S. Ghosh: J. Braz. Soc. Mech. Sci. Eng., 2020, vol. 42, pp. 572–602.

H. Liu, W. Zhang, M. Jia, Y. Yan, and Y. He: Comput. Fluids, 2018, vol. 177, pp. 20–32.

K. Song and A. Jokilaakso: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1772–88.

C.K.K. Lun, S.B. Savage, D.J. Jeffrey, and N. Chepurniy: J. Fluid Mech., 2006, vol. 140, pp. 223–56.

S.H. Hosseini, M. Fattahi, and G. Ahmadi: J. Taiwan Inst. Chem. Eng., 2016, vol. 58, pp. 107–16.

B.K. Singh, S. Roy, and V.V. Buwa: Ind. Eng. Chem. Res., 2021, vol. 60, pp. 17677–93.

M.T. Islam and A.V. Nguyen: Chem. Eng. Res. Des., 2020, vol. 159, pp. 13–26.

N.B. Ballal and A. Ghosh: Metall. Mater. Trans. B, 1981, vol. 12B, pp. 525–34.

V.B. Okhotskii: Refract. Ind. Ceram., 2001, vol. 42, pp. 411–16.

M.S. Lee, S. O’Rourke, and N.A. Molloy: Ironmak. Steelmak., 2013, vol. 28, pp. 244–49.

X. Zhou, M. Ersson, L. Zhong, and P.G. Jönsson: Steel Res. Int., 2015, vol. 86, pp. 1328–38.

Q. Li, M. Li, S.B. Kuang, and Z. Zou: JOM, 2016, vol. 68, pp. 3126–33.

J. Sun, J. Zhang, W. Lin, X. Feng, and Q. Liu: Metals, 2022, vol. 12, pp. 117–35.

Inc.: FLUENT, 2022 R1 Fluent Theory Guide, Fluent Inc., Lebanon, NH, 2022, p. 2022.

A.D. Burns, T. Frank, I. Hamill, and J.M. Shi: in 5th international conference on multiphase flow, ICMF, (ICMF: 2004), pp. 1–17.

M. Sano and K. Mori: Tetsu To Hagane-J. Iron Steel Inst. Jpn., 1976, vol. 17, pp. 344–52.

D. Gidaspow, R. Bezburuah, and J. Ding: in Fluidization VII, Proceedings of the 7th Engineering Foundation Conference on Fluidization., 1992, pp 75-82.

D.G. Schaeffer: J. Differ. Equ., 1987, vol. 66, pp. 19–50.

P.C. Johnson and R. Jackson: J. Fluid Mech., 2006, vol. 176, pp. 67–93.

C.K.K. Lun and S.B. Savage: Acta Mech., 1986, vol. 63, pp. 15–44.

W. Lou and M. Zhu: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1251–63.

J.S. Zhang, W.T. Lou, and M.Y. Zhu: J. Iron Steel Res. Int., 2022, vol. 29, pp. 1771–88.

J. Sun, J. Zhang, R. Jiang, X. Feng, and Q. Liu: Steel Res. Int., 2023, vol. 94, pp. 2200532–45.

G. Wang, S. Zhou, J.B. Joshi, G.J. Jameson, and G.M. Evans: Miner. Eng., 2014, vol. 69, pp. 165–69.

J.P. Mollicone, M. Sharifi, F. Battista, P. Gualtieri, and C.M. Casciola: Phys. Fluids, 2019, vol. 31, p. 101301.

S. Kalenko and A. Liberzon: Int. J. Multiph. Flow, 2020, vol. 133, p. 103451.

T.C.W. Lau and G.J. Nathan: J. Fluid Mech., 2016, vol. 809, pp. 72–110.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. U20A20272) and the Fundamental Research Funds for the Central Universities, NEU, (No. N2025017).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, J., Lou, W. & Zhu, M. Numerical Simulation of Particle Motion and Wall Scouring Behavior in Steelmaking Converter With Bottom Powder Injection. Metall Mater Trans B 54, 3031–3048 (2023). https://doi.org/10.1007/s11663-023-02886-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02886-2