Abstract

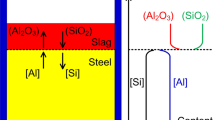

A three-dimensional species transport model in continuous casting mold has been developed to describe the interfacial reaction behavior and to clarify the evolution of composition and properties of the mold flux for high-Al steel. The reaction experiment and plant trial were conducted to verify the model predictions. The results show that the interfacial reaction rate is the main factor affecting the composition distribution of the mold flux. The reaction interface above the upflow zone of molten steel has a fast update rate, resulting in a rapid increase in the Al2O3 content in mold flux in this area. In addition, the mold flux near the nozzle stays in the liquid pool for a longer time to react with the molten steel, leading to the accumulation of Al2O3. The Al2O3 content in the solid film is slightly lower than that of the liquid pool due to the solidification of liquid mold flux in the early stage. The interfacial reaction increases the viscosity of the mold flux and reduces the thickness of the liquid film, thereby reducing the flux consumption.

Similar content being viewed by others

References

J. Hu, L. Du, W. Xu, J. Zhai, Y. Dong, Y. Liu, and R.D.K. Misra: Mater. Charact., 2018, vol. 136, pp. 20–28.

J. Hu, J. Zhang, G. Sun, L. Du, Y. Liu, Y. Dong, and R.D.K. Misra: J. Mater. Sci., 2019, vol. 54, pp. 6565–78.

S. Hwang, J. Ji, and K. Park: Mater. Sci. Eng. A, 2011, vol. 528, pp. 7267–75.

D.J. Kim and J.H. Park: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 875–86.

Q. Wang, S. Qiu, and P. Zhao: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 424–30.

T. Wu, S. He, L. Zhu, and Q. Wang: Mater. Trans., 2016, vol. 57, pp. 58–63.

M. Kim, S. Lee, J. Cho, M. Park, H. Lee, and Y. Kang: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 299–308.

Y. Kang, M. Kim, S. Lee, J. Cho, M. Park, and H. Lee: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 309–16.

M. Kim, M. Park, S. Kang, J. Park, and Y. Kang: ISIJ Int., 2018, vol. 58, pp. 686–95.

D.G.C. Robertson, B. Deo, and S. Oguchi: Ironmak. Steelmak., 1984, vol. 11, pp. 41–55.

S. Kitamura, S. Saito, K. Utagawa, H. Shibata, and D.G.C. Robertson: ISIJ Int., 2009, vol. 49, pp. 1838–44.

J. Park, S. Sridhar, and R.J. Fruehan: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 1380–88.

A. Harada, N. Maruoka, H. Shibata, and S. Kitamura: ISIJ Int., 2013, vol. 53, pp. 2110–17.

M. van Ende and I. Jung: ISIJ Int., 2014, vol. 54, pp. 489–95.

J. Shin, Y. Chung, and J. Park: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 46–59.

M. Kim and Y. Kang: Calphad, 2018, vol. 61, pp. 105–15.

J. Yang, L. Wang, Y. Li, T. Wang, L. Kong, and X. Zang: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1516–25.

J. Yang, Z. Cai, and M. Zhu: ISIJ Int., 2018, vol. 58, pp. 299–308.

M. Kawakami, S. Yokoyama, K. Takagi, M. Nishimura, and J.S. Kim: ISIJ Int., 1997, vol. 5, pp. 425–31.

F. Calderon, N. Sano, and Y. Matsushita: Metall. Mater. Trans. B, 1971, vol. 2B, pp. 3325–32.

J. Henderson, L. Yang, and G. Derge: Trans. AIME, 1961, vol. 221, pp. 56–60.

Y. Ukyo and K. Goto: Tetsu-to-Hagane, 1982, vol. 68, pp. 1981–86.

H. Keller, K. Schwerdtfeger, and K. Hennesen: Metall. Mater. Trans. B, 1979, vol. 10B, pp. 551–54.

J. Yang and M. Zhu: ISIJ Int., 2016, vol. 56, pp. 2191–98.

K. Zhang, J. Liu, and H. Cui: ISIJ Int., 2019, vol. 59, pp. 2256–63.

Acknowledgments

The authors are especially grateful to the Major Program of Liaoning Province (Grant Number 2020JH1/10100001) and the National Natural Science Foundation of China (Grant Numbers 51904046, 52274337).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, L., Xing, F., Wang, T. et al. Interfacial Reaction Model of High-Al Steel in Continuous Casting Mold. Metall Mater Trans B 54, 1546–1554 (2023). https://doi.org/10.1007/s11663-023-02780-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02780-x