Abstract

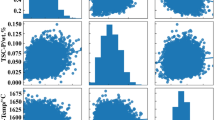

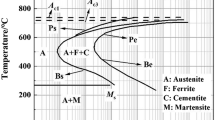

Controlling the temperature of molten steel in ladle furnace (LF)-refining process is one of the main tasks to ensure that the steelmaking-continuous casting process runs smoothly. In this work, a hybrid model based on metallurgical mechanism, isolation forest (IF), zero-phase component analysis whitening (ZCA whitening), and a deep neural network (DNN) was established to predict the temperature of molten steel in LF-refining process. The metallurgical mechanism, Pearson correlation coefficient, ZCA whitening, IF, and t-distributed stochastic neighbor embedding (t-SNE) were used to obtain the main factors affecting the temperature, analyze the correlation between two random variables, eliminate the correlation among the input variables, reduce the abnormal data of the original datasets, and visualize high-dimensional data, respectively. The single-machine-learning (ML) models, ZCA–ML models, and IF–ZCA–DNN model were comparatively examined by evaluating the coefficient of determination (R2), root-mean-square error (RMSE), mean absolute error (MAE), and hit ratio. The optimal structure of IF–ZCA–DNN model had 4 hidden layers, 45 hidden layer neurons, a learning rate of 0.03, regularization coefficient of 2 × 10−4, batch size of 128, leaky-rectified linear unit activation function, and an optimization algorithm of mini-batch stochastic gradient descent with momentum. The R2, RMSE, and MAE of the IF–ZCA–DNN model were 0.916, 2.827, and 2.048, respectively. Meanwhile, the prediction hit ratio for the temperature of IF–ZCA–DNN model in the error ranges of [− 3, 3], [− 5, 5], and [− 10, 10] were 77.9, 92.3, and 99.6 pct, respectively. This study will be beneficial to realize precise control of temperature of molten steel in LF-refining process.

Copyright 2021, copyright Taylor & Francis)

Similar content being viewed by others

References

R.Y. Yin: Iron Steel, 2021, vol. 56, pp. 4–9.

J. Li: LF Refining Technology, Metallurgical Industry Press, Beijing, 2012, pp. 135–36.

U. Camdali and M. Tunc: J. Iron Steel Res. Int., 2006, vol. 13, pp. 18–20.

O. Volkova and D. Janke: ISIJ Int., 2003, vol. 43, pp. 1185–90.

Y.J. Wu, Z.H. Jiang, M.F. Jiang, W. Gong, and D.P. Zhan: J. Iron Steel Res., 2002, vol. 14, pp. 9–12.

D.G. Hong, W.H. Han, and C.H. Yim: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3833–45.

W.J. Wang, L.F. Zhang, Y. Ren, Y. Luo, X.H. Sun, and W. Yang: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 1–7.

W.J. Yang, L.J. Wang, W. Zhang, and J.M. Li: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 3124–35.

C.A. Myers and T. Nakagaki: ISIJ Int., 2019, vol. 59, pp. 687–96.

S.K. Thakur, A.K. Das, and B.K. Jha: Steel Res. Int., 2022, vol. 93, p. 2100479.

S.H. Kwon, D.G. Hong, and C.H. Yim: Ironmak. Steelmak., 2020, vol. 47, pp. 1176–87.

L.J. Yang, W.Q. Chen, P. Yu, L.C. Li, and L.G. Zhu: Iron Steel, 2000, vol. 35, pp. 13–16.

J. Li, D.F. He, A.J. Xu, and N.Y. Tian: Steelmaking, 2012, vol. 28, pp. 50–52.

X.L. Wang, H. Zhao, and Y.G. Sun: Metal. Ind. Autom., 2007, vol. 4, pp. 5–7.

Z.C. Xin, J.S. Zhang, J. Zheng, Y. Jin, and Q. Liu: ISIJ Int., 2022, vol. 62, pp. 532–41.

K. Feng, D.F. He, A.J. Xu, and H.B. Wang: Steel Res. Int., 2016, vol. 87, pp. 79–86.

H.Y. Tang, X.C. Guo, J.L. Wang, Y. Wang, and P.F. Cheng: Chin. J. Eng., 2016, vol. 38, pp. 139–45.

X.J. Wang: IEEE CAA J. Autom. Sin., 2017, vol. 4, pp. 770–74.

G.Q. Fu, Q. Liu, Z. Wang, J. Chang, B. Wang, F.M. Xie, X.C. Lu, and Q.P. Ju: J. Univ. Sci. Technol. B, 2013, vol. 35, pp. 948–54.

W. Lv, Z.Z. Mao, and P. Yuan: J. Iron Steel Res. Int., 2012, vol. 19, pp. 21–28.

W. Lv, Z.Z. Mao, and P. Yuan: Steel Res. Int., 2012, vol. 83, pp. 288–96.

W. Lv, Z.Z. Mao, P. Yuan, and M.X. Jia: Steel Res. Int., 2014, vol. 85, pp. 405–14.

F. He, A.J. Xu, H.B. Wang, D.F. He, and N.Y. Tian: Steel Res. Int., 2012, vol. 83, pp. 1079–86.

N.K. Nath, N.K. Mandal, A.K. Singh, B. Basu, C. Bhanu, S. Kumar, and A. Ghosh: Ironmak. Steelmak., 2006, vol. 33, pp. 140–50.

H.X. Tian, Z.Z. Mao, and Y. Wang: ISIJ Int., 2008, vol. 48, pp. 58–62.

H.X. Tian, Z.Z. Mao, and A.N. Wang: ISIJ Int., 2009, vol. 49, pp. 58–63.

H.X. Tian, Y.D. Liu, K. Li, R.R. Yang, and B. Meng: ISIJ Int., 2017, vol. 57, pp. 841–50.

H.X. Tian, Z.Z. Mao, and Z. Zhao: Chin. J. Sci. Instrum., 2008, vol. 29, pp. 2658–62.

C. Chen, N. Wang, and M. Chen: ISIJ Int., 2021, vol. 61, pp. 1908–14.

L.L. Zou, J.S. Zhang, Y.S. Han, F.Z. Zeng, Q.H. Li, and Q. Liu: Metals, 2021, vol. 11, pp. 1976–92.

Z.C. Xin, J.S. Zhang, Y. Jin, J. Zheng, and Q. Liu: Int. J. Miner. Metall. Mater., 2023, vol. 30, pp. 335–44.

K. Sano, S. Matsuda, S. Tohyama, D. Komura, and C. Sutoh: Sci. Rep., 2020, vol. 10, pp. 11714–22.

G.Q. Huang, X.X. Zhao, and Q.Q. Lu: J. Saf. Environ., 2022, vol. 22, pp. 3412–23.

Q.S. Deng and G.P. Mei: in 2009 IEEE International Conference on Granular Computing (GRC 2009), China, 2009, pp. 126–31.

F.T. Liu, K.M. Ting, and Z.H. Zhou: in 8th IEEE International Conference on Data Mining (IEEE, ICDM 2008), Pisa, Italy, 2008, pp. 413–22.

Z.C. Xin, J.S. Zhang, J.G. Zhang, Y. Jin, J. Zheng, and Q. Liu: Ironmak. Steelmak., 2021, vol. 48, pp. 1123–32.

J.D. Rodriguez, A. Perez, and J.A. Lozano: IEEE Trans. Pattern Anal. Mach. Intell., 2010, vol. 32, pp. 569–75.

L.V.D. Maaten and G. Hinton: J. Mach. Learn. Res., 2008, vol. 9, pp. 2579–2605.

A.C. Belkina, C.O. Ciccolella, R. Anno, R. Halpert, J. Spidlen, and J.E.S. Cappione: Nat. Commun., 2019, vol. 10, pp. 5415–27.

R.Z. Bian, J. Zhang, L. Zhou, P. Jiang, B.Q. Chen, and Y.H. Wang: J. Comput. Aided Des. Comput. Graph., 2021, vol. 33, pp. 1746–54.

K. Pearson: Philos. Trans. R. Soc. A, 1895, vol. 186, pp. 343–414.

F.T. Liu, K.M. Ting, and Z.H. Zhou: ACM Trans. Knowl. Discov. Data, 2012, vol. 6, pp. 1–39.

K. Hornik, M. Stinchcombe, and H. White: Neural Netw., 1989, vol. 2, pp. 359–66.

Y. Liu, Q. Zhao, W. Yao, X. Ma, and L. Liu: Sci. Rep., 2019, vol. 9, pp. 19751–63.

S. Gouravaraju, J. Narayan, R.A. Sauer, and S.S. Gautam: J. Adhes., 2023, vol. 99, pp. 92–115.

G.B. Huang, Q.Y. Zhu, and C.K. Siew: Neurocomputing, 2006, vol. 70, pp. 489–501.

H.Z. Chen, J.P. Yang, X.C. Lu, X.Z. Yu, and Q. Liu: Chin. J. Eng., 2018, vol. 40, pp. 815–21.

J. Wang, S.Y. Lu, S.H. Wang, and Y.D. Zhang: Multimed. Tools Appl., 2022, vol. 81, pp. 41611–60.

Z. Zhang, L.L. Cao, W.H. Lin, J.K. Sun, X.M. Feng, and Q. Liu: Chin. J. Eng., 2019, vol. 41, pp. 1052–60.

W.Y. Deng, Q.H. Zheng, and L. Chen: in 2009 IEEE Symposium on Computational Intelligence and Data Mining, (CIDM 2009), Nashville, TN, USA, 2009, pp. 389–95.

Z.C. Xin, J.S. Zhang, W.H. Lin, J.G. Zhang, Y. Jin, J. Zheng, J.F. Cui, and Q. Liu: Ironmak. Steelmak., 2021, vol. 48, pp. 275–83.

T.M. Cover and P.E. Hart: IEEE Trans. Inf. Theory, 1967, vol. 13, pp. 21–27.

H. Peter: Machine Learning in Action, Manning Publications, Greenwich, 2012, pp. 15–25.

Y. LeCun, Y. Bengio, and G.E. Hinton: Nature, 2015, vol. 521, pp. 436–44.

J.P. Yang, J.S. Zhang, W.D. Guo, S. Gao, and Q. Liu: ISIJ Int., 2021, vol. 61, pp. 2100–110.

H.X. Yang, J.H. Liu, H.W. Sun, and H.G. Zhang: IEEE Access, 2020, vol. 8, pp. 112805–13.

L.S. Shapley: A value for n-person games, Princeton University Press, Princeton, NJ, 1953, pp. 307–17.

P. Giudici and E. Raffinetti: Qual. Reliab. Eng. Int., 2022, vol. 38, pp. 1318–26.

J. Bae, Y.R. Li, N. Stahl, G. Mathiason, and N. Kojola: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1632–45.

J. Nickolls and W.J. Dally: IEEE Micro, 2010, vol. 30, pp. 56–69.

J. Prakash, U. Agarwal, and P.K. Yalavarthy: Sci. Rep., 2021, vol. 11, pp. 18536–45.

J. Schmidhuber: Neural Netw., 2015, vol. 61, pp. 85–117.

Acknowledgments

This project is funded by the National Natural Science Foundation of China, under Grant Number 51974023, and the funding of State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, under Grant Number 41621005.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xin, Zc., Zhang, Js., Zhang, Jg. et al. Predicting Temperature of Molten Steel in LF-Refining Process Using IF–ZCA–DNN Model. Metall Mater Trans B 54, 1181–1194 (2023). https://doi.org/10.1007/s11663-023-02753-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02753-0