Abstract

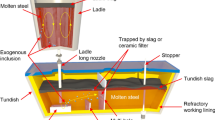

The cleanliness of high-quality steel largely depends on the distribution and characteristics of non-metallic inclusions. The removal of inclusions in the tundish can be studied by simulation, but the traditional criterion tends to predict high removal rates. In this study, the touched inclusion fraction at the free surface of the tundish was analyzed by considering the fundamental forces acting on the inclusions. An optimized criterion based on the direction of the inclusion balance force was established to judge the inclusion removal behavior. The simulation results obtained using the optimized criterion were more consistent with actual industrial trial results. In addition, the connection between the removal behaviors of inclusions of different sizes and flow time of liquid steel was studied using the new criterion. The optimized criterion for inclusion removal created a prerequisite for improving the combined model and dead zone volume. The method for calculating the dead zone volume was upgraded.

Graphical Abstract

Similar content being viewed by others

References

Y. Sahai: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2095–2106.

Y. Miki and B.G. Thomas: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 639–54.

K. Chattopadhyay, M. Isac, and R.I. Guthrie: ISIJ Int., 2011, vol. 50, pp. 331–48.

D. Mazumdar: Steel Res. Int., 2019, vol. 90, p. 1800279.

H. Tanaka, R. Nishihara, R. Miura, R. Tsujino, T. Kimura, and T. Nishi: ISIJ Int., 1994, vol. 34, pp. 868–75.

K. Chattopadhyay, M. Isac, and R.I. Guthrie: ISIJ Int., 2011, vol. 51, pp. 573–80.

C. Gu, W.Q. Liu, J.H. Lian, and Y.P. Bao: Int. J. Miner. Metall. Mater., 2021, vol. 28, pp. 826–34.

W. Xiao, Y.P. Bao, C. Gu, M. Wang, Y. Liu, and Y.S. Huang: Int. J. Miner. Metall. Mater., 2021, vol. 28, pp. 804–15.

C. Liu, R.I. Revilla, D.W. Zhang, Z.Y. Liu, A. Lutz, and F. Zhang: Corros. Sci., 2018, vol. 138, pp. 96–104.

J.H. Park and H. Todoroki: ISIJ Int., 2010, vol. 50, pp. 1333–46.

C.J. Hua, Y.P. Bao, and M. Wang: Powder Technol., 2021, vol. 393, pp. 405–20.

C.B. Shi, X.C. Chen, and H.J. Guo: Int. J. Miner. Metall. Mater., 2012, vol. 19, pp. 295–302.

J.H. Park: Mat Sci Eng A-Struct, 2008, vol. 472, pp. 43–51.

K.H. Tacke and J.C. Ludwig: Steel Res. Int., 1987, vol. 58, pp. 262–70.

A.W. Cramb and I. Jimbo: Steel Res. Int., 1989, vol. 60, pp. 157–65.

Y. Chung and A.W. Cramb: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 957–71.

M. Valdez, K. Prapakorn, and A.W. Cramb: Ironmak. Steelmak., 2002, vol. 29, pp. 47–52.

P.Y. Ni, L.T. Jonsson, M. Ersson, and P.G. Jönsson: Steel Res. Int., 2017, vol. 88, p. 1600155.

S.K. Ray, M. Isac, and R.I.L. Guthrie: Ironmak. Steelmak., 2011, vol. 38, pp. 173–80.

S. García Hernández, J.D.J. Barreto, J.A. Ramos Banderas, and G. Solorio Diaz: Steel Res. Int., 2010, vol. 81, pp. 453–60.

K. Takahashi, M. Ando, and T. Ishii: ISIJ Int., 2014, vol. 54, pp. 304–10.

Q. Yue, C.B. Zhang, and X.H. Pei: Ironmak. Steelmak., 2017, vol. 44, pp. 227–36.

A. Cwudziński: Steel Res. Int., 2010, vol. 81, pp. 123–31.

C. Yao, M. Wang, R.X. Zheng, M.X. Pan, J.Y. Rao, and Y.P. Bao: Metals, 2020, vol. 10, p. 1111.

A. Kumar, D. Mazumdar, and S.C. Koria: ISIJ Int., 2008, vol. 48, pp. 38–47.

D.Y. Sheng: Metals, 2020, vol. 10, p. 1213.

C. Liu, S.F. Yang, J.S. Li, L.B. Zhu, and X.G. Li: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1882–92.

S.F. Yang, J.S. Li, C. Liu, L.Y. Sun, and H.B. Yang: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2453–63.

Y. Sahai and T. Emi: ISIJ Int., 1996, vol. 36, pp. 667–72.

G.C. Wang, M.F. Yun, C.M. Zhang, and G.D. Xiao: ISIJ Int., 2015, vol. 55, pp. 984–92.

J. Li, G.H. Wen, P. Tang, and M.M. Zhu: Ironmak. Steelmak., 2012, vol. 39, pp. 140–46.

C. Yao, M. Wang, M.X. Pan, and Y.P. Bao: J. Iron Steel Res. Int., 2021, vol. 28, pp. 1114–24.

E. Gutiérrez, S. Garcia-Hernandez, and J. Barreto: Steel Res. Int., 2019, vol. 90, p. 1900328.

H.T. Ling, L.F. Zhang, and H. Li: Metall. Mater. Trans. B., 2016, vol. 47B, pp. 2991–3012.

Competing Interest

The authors declare no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 4, 2022; accepted February 12, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yao, C., Wang, M., Zhu, H. et al. Mathematical Study of Realistic Removal Rates of Non-metallic Inclusions in Continuous Casting Tundish Using Optimized Criterion. Metall Mater Trans B 54, 1144–1158 (2023). https://doi.org/10.1007/s11663-023-02750-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-023-02750-3