Abstract

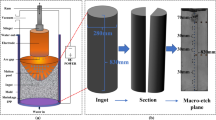

Modeling vacuum arc remelting (VAR) is very challenging as this process involves a wide range of physical phenomena and complex interactions. The formations of macrosegregation and channel segregation during VAR are essential issues and require deep investigations. A two-dimensional transient model is developed to study the macrosegregation of NbTi alloy and predict the occurring tendency of channel segregation by dimensionless Rayleigh number. The most important feature is a full consideration of electromagnetic interaction, multi-force driven convection, heat as well as solute transfers, and time-variant characteristic values of microstructure. The simulation results reveal that the Lorentz force induced by the electromagnetic interaction mainly controls the macrosegregation distribution in the ingot. The effects of enhancing cooling on macrosegregation are studied by filling helium into an air gap formed between the inner wall of the crucible and the outer wall of the ingot. As the cooling efficiency is increased with filling pressure, there exists an optimized filling pressure to avoid the formation of a positive segregation in the central region. The homogenization of the ingot is improved. The simulated macrosegregation and channel segregation show fairly good qualitative agreement with the experimental results. This study elucidates the mechanism of enhanced cooling reducing channel segregation and highlights an economic and controllable method to produce homogenized ingots during VAR.

Similar content being viewed by others

Abbreviations

- B θ :

-

Magnetic field intensity (A m−1)

- C l :

-

Liquid concentrations (wt pct)

- C s :

-

Solid concentrations (wt pct)

- C mix :

-

Mixture concentration (wt pct)

- c p :

-

Specific heat (J kg−1 K−1)

- D :

-

Solute diffusion coefficient (m2 s−1)

- \(\overrightarrow{{e}_{r}}\) :

-

Current unit along radius direction

- \(\overrightarrow{{e}_{y}}\) :

-

Current unit along vertical direction

- f s , f l :

-

Fractions of solid and liquid

- g :

-

Acceleration of gravity (m s−2)

- g l , g c :

-

Ingot and crucible temperature jump distance (mm)

- G :

-

Temperature gradient (K m−1)

- G k :

-

Turbulent energy terms

- h :

-

Enthalpy (J kg−1)

- \(\overrightarrow{J}\) :

-

Current density (A m−2)

- \({J}_{r}\) :

-

Current density along radius direction

- \({J}_{y}\) :

-

Current density in the gravity direction

- L :

-

Latent heat (J kg−1)

- K :

-

Effective permeability (m2)

- K par :

-

Parallel permeability (m2)

- K perp :

-

Perpendicular permeability (m2)

- k gas :

-

Thermal conductivity of helium gas (W m−2 K−1)

- k eff :

-

Effective thermal conductivity (W m−1 K−1)

- k 0 :

-

Equivalent partition coefficient

- t :

-

Time (s)

- P :

-

Pressure (kPa)

- R :

-

Solidification rate (m s−1)

- r :

-

Ingot radius (m)

- T :

-

Reference temperature (K)

- T l :

-

Liquidus temperature (K)

- T s :

-

Solidus temperature (K)

- T arc :

-

Temperature of arc discharge (K)

- T top :

-

Temperature of the upper surface (K)

- \(\overrightarrow{U}\) :

-

Velocity vector

- \({\overrightarrow{U}}_{\text{cast}}\) :

-

Casting velocity

- \({U}_{\text{meltt}}\) :

-

Melting rate

- μ eff :

-

Effective viscosity (Pa s)

- μ trub :

-

Intramolecular viscosity (Pa s)

- μ t :

-

Turbulent viscosity (Pa s)

- μ l :

-

Molecular dynamics viscosity (Pa s)

- λ 1 :

-

Primary and dendrite arm spacing (μm)

- λ 2 :

-

Secondary dendrite arm spacing (μm)

- ρ :

-

Density of melt (kg m−3)

- μ 0 :

-

Magnetic permeability (H m−1)

- σ :

-

Electrical conductivity (\(\Omega \)m)−1

- φ :

-

Electrical potential (V)

- α :

-

Angle between flow vector and horizontal

- ε top :

-

Emissivity

- Constants :

-

\({\sigma }_{k}\), \({C}_{1\varepsilon }\), \({C}_{2\varepsilon }\), \({r}_{1}\), \({r}_{2}\), \({r}_{3}\), \({q}_{1}\), \({q}_{2}\), \({a}_{1}\), \({a}_{2}\),\({p}_{1}\) And \({p}_{2}\)

References

M. Niinomi, M. Nakai, and J. Hieda: Acta Biomater., 2012, vol. 8, pp. 3888–3903.

Z.Y. Zhang, S. Matsumoto, S. Choi, R. Teranishi, and T. Kiyoshi: Physica C (Amsterdam Neth.), 2011, vol. 471, pp. 1547–49.

Q. Wang, G. Cui, and H. Chen: J. Alloys Compd., 2021, vol. 868, 159106.

A. Patel, D. W. Tripp and D. Fiore: Proceedings of the 2013 International Symposium on Liquid Metal Processing and Casting, 2013, pp. 239–44.

W.J. Kroll: Vacuum, 1951, vol. 1, pp. 163–84.

R. Bhar, A. Jardy, P. Chapelle, and V. Descotes: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2492–2503.

H. Song, S. Lee, and K. Lee: Int. J. Refract. Met. Hard Mater., 2021, vol. 99, 105595.

J.J. Beaman, R.L. Williamson, D.K. Melgaard, and J. Hamel: ASME Int. Mech. Eng. Congr. Expo., 2005, vol. 136, pp. 1059–67.

F. Lopez, J. Beaman, R. Williamson, E. Taleff and T. Watt: Proceedings of the 2013 International Symposium on Liquid Metal Processing and Casting, 2013, pp. 245–52

T.A. Ivanoff, T.J. Watt, and E.M. Taleff: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 700–15.

Y. Cao, Y. Miao, D. Li, Y. Chen, P. Fu, H. Liu, X. Kang, H. Liu, and C. Sun: Metall. Mater. Trans. B, 2022, vol. 26B, pp. 1858–74.

H. Ge, J. Li, Q. Guo, F. Ren, M. Xia, J. Yao, and J. Li: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 2992–3003.

V. Hatič, B. Mavrič, and B. Šarler: Eng. Anal. Bound. Elem., 2020, vol. 113, pp. 191–203.

A. Kumar, M. Založnik, H. Combeau, G. Lesoult, and A. Kumar: Int. J. Heat Mass Transfer, 2021, vol. 164, 120602.

N. Ren, J. Li, C. Panwisawas, M. Xia, H. Dong, and J. Li: Acta Mater., 2021, vol. 206, 116620.

P. King, M. Cibula and J. Motley: 11th International Symposium on High-Temperature Metallurgical Processing. A, 2020, pp. 273–87.

L. Yuan and P.D. Lee: Acta Mater., 2012, vol. 60, pp. 4917–26.

V. Descotes, T. Quatravaux, J.-P. Bellot, S. Witzke, and A. Jardy: Metals, 2020, vol. 10, p. 541.

H.E. Mir, A. Jardy, J.-P. Bellot, P. Chapelle, D. Lasalmonie, and J. Senevat: J. Mater. Process. Technol., 2010, vol. 210, pp. 564–72.

C.R. Woodside, P.E. King, and C. Nordlund: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 154–65.

Z. Yang, X. Zhao, H. Kou, J. Li, R. Hu, and L. Zhou: Trans. Nonferrous Met. Soc. China, 2010, vol. 20, pp. 1957–62.

E. Karimi-Sibaki, A. Kharicha, M. Wu, A. Ludwig, and J. Bohacek: Metall. Mater. Trans. B, 2019, vol. 51B, pp. 222–35.

Z. Yang, H. Kou, X. Zhao, J. Li, R. Hu, H. Chang, and L. Zhou: J. Shanghai Jiaotong Univ., 2011, vol. 16, p. 133.

E. Karimi-Sibaki, A. Kharicha, M. Abdi, A. Vakhrushev, M. Wu, A. Ludwig, and J. Bohacek: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 3354–62.

K. Pericleous, G. Djambazov, M. Ward, L. Yuan, and P.D. Lee: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 5365–76.

P.O. Delzant, B. Baqué, P. Chapelle, and A. Jardy: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 958–68.

D. Zagrebelnyy and M.J.M. Krane: Metall. Mater. Trans. B, 2009, vol. 40B, pp. 281–88.

A. Patel and D. Fiore: IOP Conf. Ser., 2016, vol. 143, p. 012017.

B. Zhu, Z. Chen, Y. Cao, Y. Liu, X. Kang, Y. Chen, H. Liu, P. Fu, Y. Luan, and D. Li: Materials, 2021, vol. 14, p. 796.

Y. Menni, H. Ahmad, H. Ameur, S. Askar, T. Botmart, M. Bayram, and G. Lorenzini: Case Stud. Therm. Eng., 2022, vol. 31, 101824.

A. Kao, N. Shevchenko, S. He, P.D. Lee, S. Eckert, and K. Pericleous: JOM, 2020, vol. 72, pp. 3645–51.

T. Kajatani, J.M. Drezet, and M. Rappaz: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1479–91.

P. Peng: J. Alloys Compd., 2019, vol. 798, pp. 210–19.

M. Seredyński and J. Banaszek: Int. J. Heat Mass Transfer, 2021, vol. 173, 121221.

D. Liu, B. Sang, X. Kang, and D. Li: Metall. Mater. Trans. B, 2010, vol. 42B, pp. 210–23.

R. Pardeshi, V.R. Voller, A.K. Singh, and P. Dutta: Int. J. Heat Mass Transfer, 2008, vol. 51, pp. 3399–3409.

Y.F. Cao, Y. Chen, and D.Z. Li: Acta Mater., 2016, vol. 107, pp. 325–36.

D. Li, X.-Q. Chen, P. Fu, X. Ma, H. Liu, Y. Chen, Y. Cao, Y. Luan, and Y. Li: Nat. Commun., 2014, vol. 5, pp. 1–8.

A. Xu, L. Shi, and H.-D. Xi: Int. J. Heat Mass Transfer, 2019, vol. 140, pp. 359–70.

M.T. Rad, P. Kotas, and C. Beckermann: Metall. Mater. Trans. A, 2013, vol. 44A, pp. 4266–81.

Y.F. Cao, Y. Chen, P. Fu, H.W. Liu, and D.Z. Li: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 2260–73.

N. Talat, B. Mavrič, V. Hatić, S. Bajt, and B. Šarler: Eng. Anal. Bound. Elem., 2018, vol. 87, pp. 78–89.

Acknowledgments

This work was supported by the National Science and Technology Major Project (Grant No. 2017-VII-0008-0101), the National Natural Science Foundation (Grant Nos. 52031013 and U1708252), the National Key Research and Development Program (Grant No. 2018YFA0702900), and the Project to Strengthen Industrial Development at the Grass-roots Level (Grant No. TC190A4DA/35).

Competing interests

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guan, J., Miao, Y., Chen, Z. et al. Modeling of Macrosegregation Formation and the Effect of Enhanced Cooling During Vacuum Arc Remelting Solidification of NbTi Alloy Ingot. Metall Mater Trans B 53, 4048–4062 (2022). https://doi.org/10.1007/s11663-022-02664-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02664-6