Abstract

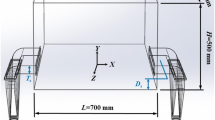

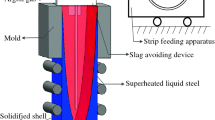

In order to improve the preparation efficiency of high-purity silicon, a new method of rotary segregation purification has been developed to prepare polysilicon. Numerical simulation based on ANSYS19.0 software and water model experiments were used to study the distribution of flow field and optimize the impurity removal process. A numerical simulation model suitable for rotating interface is established. The simulation result is in good agreement with the water model experiment. A vortex flow is found in the middle of the mold when the mold insertion depth is 90 mm. The vortex is conducive to the thinning of the impurity enrichment layer at the solid–liquid interface. With the mold insertion depth increases from 90 to 170 mm, two vortex flows appear in the middle and bottom of the mold, respectively. Moreover, setting the mold rotation rate at 100 rpm can contribute to a more stable flow field and a higher melt flow velocity. When the diffusion layer thickness is less than 0.1 mm, the impurity segregation coefficient can approach close to its equilibrium segregation coefficient, indicating that impurity segregation be effectively enhanced by increasing the rotation rate of mold, strengthening the effect of solidification rate and increasing the rotational speed. Industrial tests were carried out at the 100 kg level. The result shows that the rotary segregation method and equipment can achieve the removal of very low impurity in silicon (99.999 pct), and SoG-Si (99.9999 pct) was obtained. This method provides a new way for silicon purification, and it is believed that better results can be obtained through continuous improvement.

Similar content being viewed by others

References

F. Ebrahimfar and M. Ahmadian: SILICON, 2019, vol. 11, pp. 1979–87.

C. Zhang, H. Lai, Y. Zhang, Z. Sheng, J. Li, P. Xing, and X. Luo: Sep. Purif. Technol., 2020, vol. 232, 115954.

C. Lu, T. Tang, Z. Sheng, P. Xing, and X. Luo: Vacuum, 2017, vol. 143, pp. 7–13.

H.J. Su, J. Zhang, L. Liu, and H.Z. Fu: Adv. Mater. Res., 2011, vol. 311–313, pp. 1389–92.

M.A. Martorano, J.B. Ferreira Neto, T.S. Oliveira, and T.O. Tsubaki: Metall. Mater. Trans. A, 2011, vol. 42, pp. 1870–86.

S. Wen, D. Jiang, S. Shi, Y. Tan, P. Li, Z. Gu, and X. Zhang: Vacuum, 2016, vol. 125, pp. 75–80.

Y. Li, Y. Tan, J. Li, and K. Morita: J. Alloy Compd., 2014, vol. 611, pp. 267–72.

Y. Lei, W. Ma, L. Sun, J. Wu, Y. Dai, and K. Morita: Sci. Technol. Adv. Mat., 2016, vol. 17, pp. 12–19.

G. Lv, Y. Bao, Y. Zhang, Y. He, and W. Ma: Mat. Sci. Semicon. Proc., 2018, vol. 81, pp. 139–48.

X. Chen, Y. Zhong, T. Zheng, Z. Shen, J. Wang, L. Fan, Y. Zhai, M. Peng, B. Zhou, W. Ren, Z. Lei, Z. Ren, and Q. He: J. Alloys Compd., 2017, vol. 714, pp. 39–46.

B. Zhou, W. Chen, Z. Li, R. Yue, G. Liu, and X. Huang: J. Cryst. Growth, 2018, vol. 483, pp. 164–68.

S. Shi, P. Li, D. Jiang, Y. Tan, X. Li, J. Yang, L. Zhang, F. Wang, J. Li, and H.M.N. ul Huda Khan Asghar: Mater. Sci. Semicond. Process., 2019, vol. 96, pp. 53–58.

S. Shi, Y. Tan, D. Jiang, S. Qin, X. Guo, and H.M.N. ul H.K. Asghar: Sep. Purif. Technol., 2015, vol. 152, pp. 32–36.

N. Yuge, K. Hanazawa, and Y. Kato: Mater. Trans., 2004, vol. 45, pp. 850–57.

T.P. Nguyen, Y.-T. Hsieh, J.-C. Chen, C. Hu, and H.B. Nguyen: J. Cryst. Growth, 2017, vol. 468, pp. 514–25.

Y. Tsunooka, N. Kokubo, G. Hatasa, S. Harada, M. Tagawa, and T. Ujihara: CrystEngCom, 2018, vol. 20, pp. 6546–50.

M. Jahoda, L. Tomášková, and M. Moštěk: Chem. Eng. Res. Des., 2009, vol. 87, pp. 460–67.

W. He, W. Lu, S. Xu, M. Huang, and H. Li: Chem. Eng. Res. Des., 2019, vol. 147, pp. 278–91.

S.S. Hoseini, G. Najafi, B. Ghobadian, and A.H. Akbarzadeh: Chem. Eng. J., 2021, vol. 413, 127497.

C.-Y. Ge, J.-J. Wang, X.-P. Gu, and L.-F. Feng: Chem. Eng. Res. Des., 2014, vol. 92, pp. 1027–36.

A. Heidari: Chin. J. Chem. Eng., 2020, vol. 28, pp. 2733–45.

X. Duan, X. Feng, C. Peng, C. Yang, and Z. Mao: Chin. J. Chem. Eng., 2020, vol. 28, pp. 2235–47.

M. Frey, L. Violet, D. Richard, and P. Fongarland: Chem. Eng. J., 2020, vol. 383, 122958.

B. Delacroix, J. Rastoueix, L. Fradette, F. Bertrand, and B. Blais: Chem. Eng. Sci., 2021, vol. 230, 116137.

B. Blais, M. Lassaigne, C. Goniva, L. Fradette, and F. Bertrand: Comput. Chem. Eng., 2016, vol. 85, pp. 136–46.

A.K. Pukkella, R. Vysyaraju, V. Tammishetti, B. Rai, and S. Subramanian: Chem. Eng. J., 2019, vol. 358, pp. 621–33.

Q.-Q. Xiong, Z. Chen, S.-W. Li, Y.-D. Wang, and J.-H. Xu: Chem. Eng. Sci., 2018, vol. 185, pp. 157–67.

M. Avinash Kumar, M. Srinivasan, and P. Ramasamy: Mater. Res. Express, 2019, vol. 6, p. 105912.

T. Kleiner, M. Gottanka, A. Stary, S. Rehfeldt, E. Bertakis, and H. Klein: Chem. Ing. Tech., 2020, vol. 92, pp. 1065–73.

R. Bhar, A. Jardy, P. Chapelle, and V. Descotes: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 2492–2503.

W. Dai, G. Cheng, G. Zhang, Z. Huo, P. Lv, Y. Qiu, and W. Zhu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 611–27.

K. Zhu, P. Yu, N. Yuan, and J. Ding: Int. J. Heat Mass Transf., 2018, vol. 127, pp. 413–25.

S.K. Naeeni and L. Pakzad: Int. J. Multiph. Flow, 2019, vol. 120, 103100.

Q. Fang, H. Zhang, J. Wang, C. Liu, and H. Ni: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1705–17.

S. Eckert, P.A. Nikrityuk, D. Räbiger, K. Eckert, and G. Gerbeth: Metall. Mater. Trans. B, 2007, vol. 38, pp. 977–88.

B. Zhu, B. Zhang, and K. Chattopadhyay: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 898–905.

Z. Sun, C. Hu, C. Liu, G. Lu, and J. Yu: Can. J. Chem. Eng., 2017, vol. 95, pp. 467–74.

S.E. Mousavi, M.R. Choudhury, and Md.S. Rahaman: Chem. Eng. J., 2019, vol. 361, pp. 690–702.

X. Guan, X. Li, N. Yang, and M. Liu: Chem. Eng. J., 2020, vol. 386, 121554.

J. Chéron, C. Loubière, S. Delaunay, A.-G. Guezennec, and E. Olmos: Hydrometallurgy, 2020, vol. 197, 105490.

A. Wodołażski: Int. J. Multiph. Flow, 2020, vol. 123, 103162.

G. Wei, R. Zhu, B. Han, S. Yang, K. Dong, and X. Wu: Metall. Mater. Trans. B, 2020, vol. 51B, pp. 1101–12.

T. Kawasaki and K. Kim: Sci. Rep., 2019, vol. 9, p. 8118.

Acknowledgments

This work was financially supported by the National Key R&D Program of China (2018YFC1901801), the National Natural Science Foundation of China (Nos. 51934006, U1902219). We thank William Leo, PhD, from Research Cloud, Australia Group, for editing the English text of a draft of this manuscript.

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Numerical Simulation of Flow Field During the Process of Rotating Segregation Purification of Silicon for SoG-Si.”

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shang, R., Qian, G., Wang, Z. et al. Numerical Simulation of Flow Field Optimizing the Rotating Segregation Purification of Silicon for SoG-Si. Metall Mater Trans B 53, 2657–2674 (2022). https://doi.org/10.1007/s11663-022-02558-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02558-7